Method, equipment and system for drilling

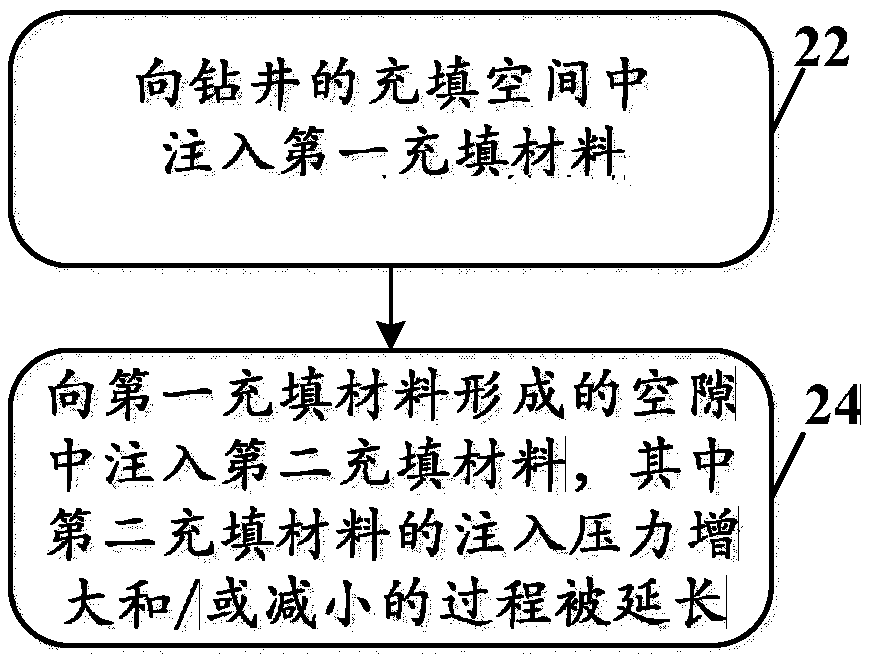

A technology of drilling and injection equipment, which is applied in the cementing and abandonment fields of oil and natural gas drilling, which can solve the problems of polluting shallow water, endangering the ground environment and personal safety, leakage, etc., and achieve the effect of minimizing expansion/contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

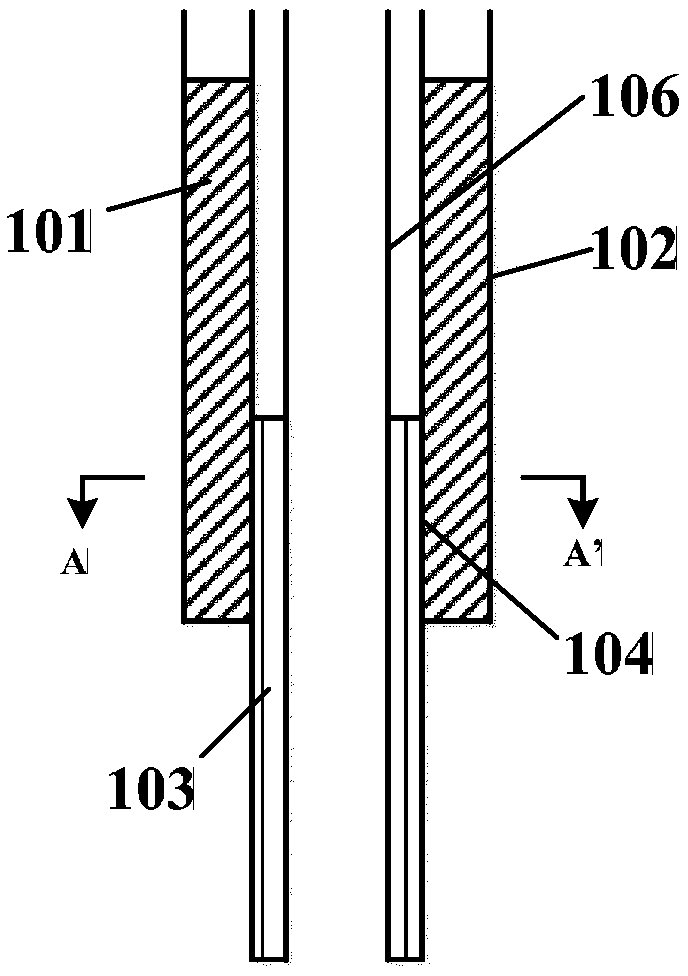

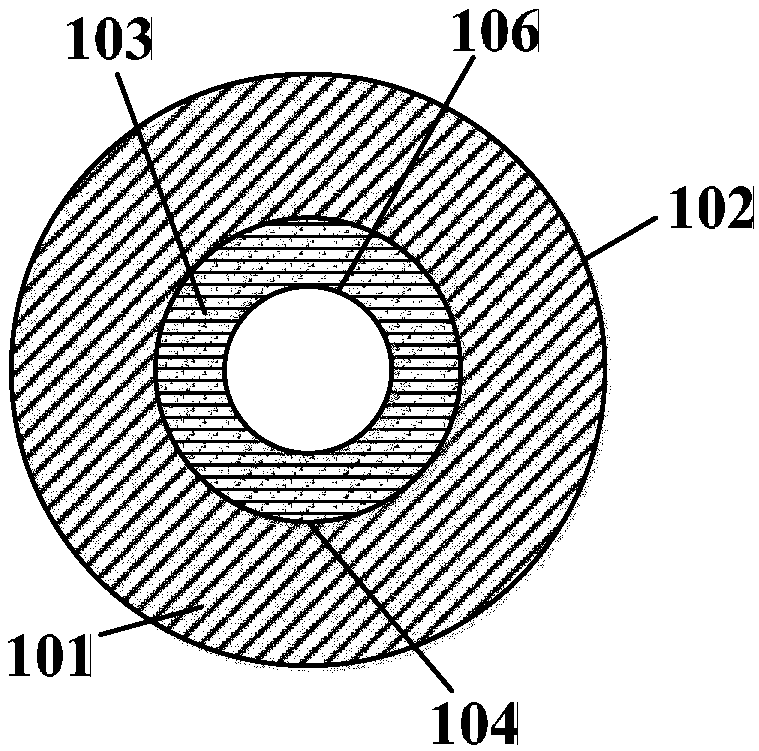

[0031] Figure 1a is a schematic diagram of filling the filling space of the well with cement, Figure 1b for Figure 1a The cross-sectional view of the structure in section AA'. The three sleeves are respectively: a first (outer) sleeve 102 located on the outermost side, a second sleeve 104 located in the middle, and a third sleeve 106 located inside. The annulus between the first casing 102 and the second casing 104 forms a filling space 101, and the annulus between the second casing 104 and the third casing 105 forms another filling space 103, as shown in the figure As shown by the linear and dotted shaded areas of , both filled spaces are filled with a primary fill material, such as cement.

[0032] Injecting the first filling material such as cement between the casings or between the casing and the well wall is known in the art for well cementing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com