Two-dimensional covalent organic framework modified flexible fiber fabric and preparation method thereof

A covalent organic framework, flexible fiber technology, applied in the direction of fiber type, fiber treatment, textile and paper making, etc., can solve the problems of low friction coefficient, large local bearing load, thinning and drying of lubricating film, etc., to achieve optimal swing Effect of friction state, reduction of oscillating friction moment, good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a two-dimensional covalent organic framework modified flexible fiber fabric, comprising the following steps:

[0035] Mix 2,4,6-tris(4-aminophenyl)-1,3,5-triazine and 2,5-dihydroxyterephthalaldehyde for polymerization to obtain a two-dimensional covalent organic framework;

[0036] Mix the two-dimensional covalent organic framework, tetrahydrofuran, diethyl azodicarboxylate, triphenylphosphine and PEG2000 for Mitsunobu etherification reaction to obtain 2D COF-PEG2000;

[0037] Mixing the 2D COF-PEG2000 and a dispersant to obtain a nano-lubricant impregnation solution;

[0038] The PTFE composite fiber fabric is soaked in the nano-lubricant impregnation solution and then dried to obtain the two-dimensional covalent organic framework modified flexible fiber fabric.

[0039] In the present invention, 2,4,6-tris(4-aminophenyl)-1,3,5-triazine and 2,5-dihydroxyterephthalaldehyde are mixed and polymerized to obtain a two-dimension...

Embodiment 1

[0059] a. Preparation of two-dimensional covalent organic framework (2D COF):

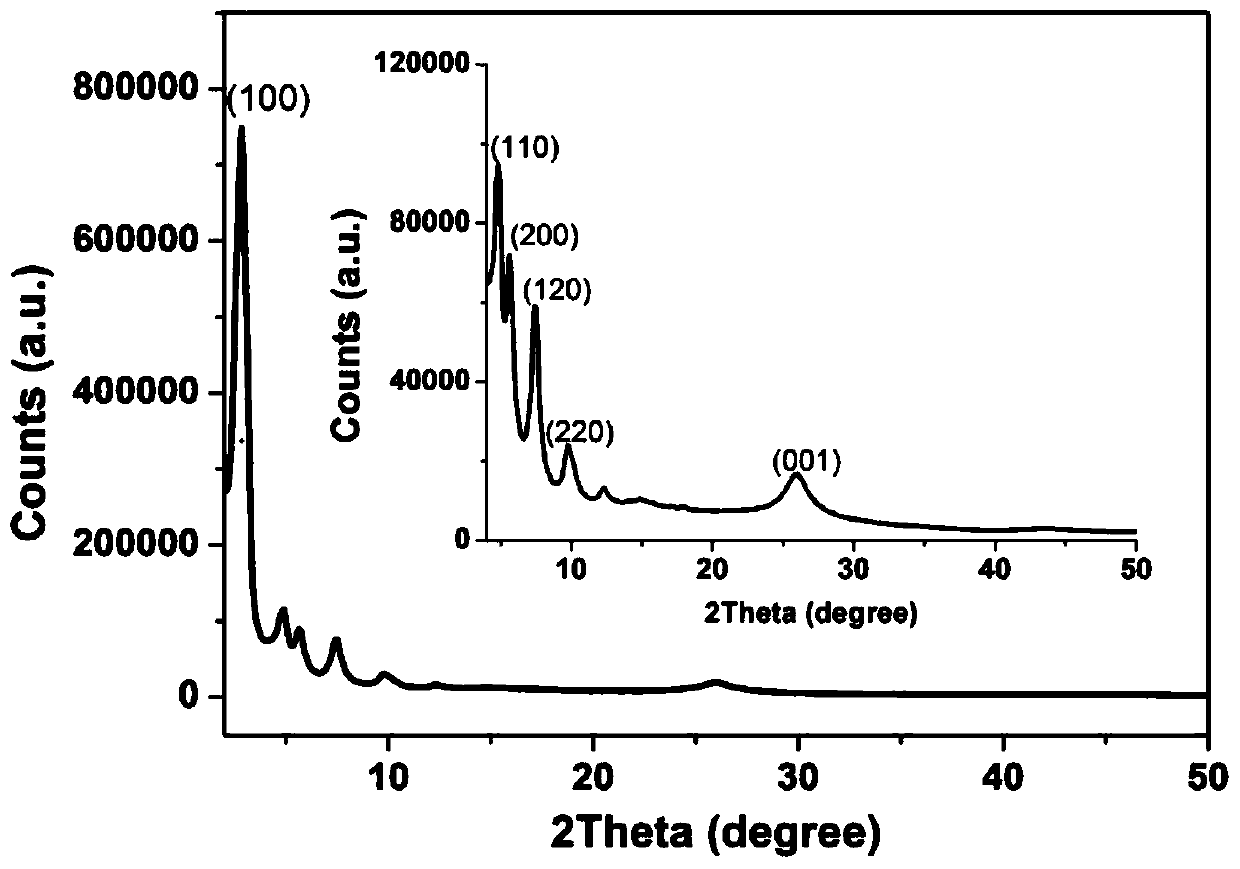

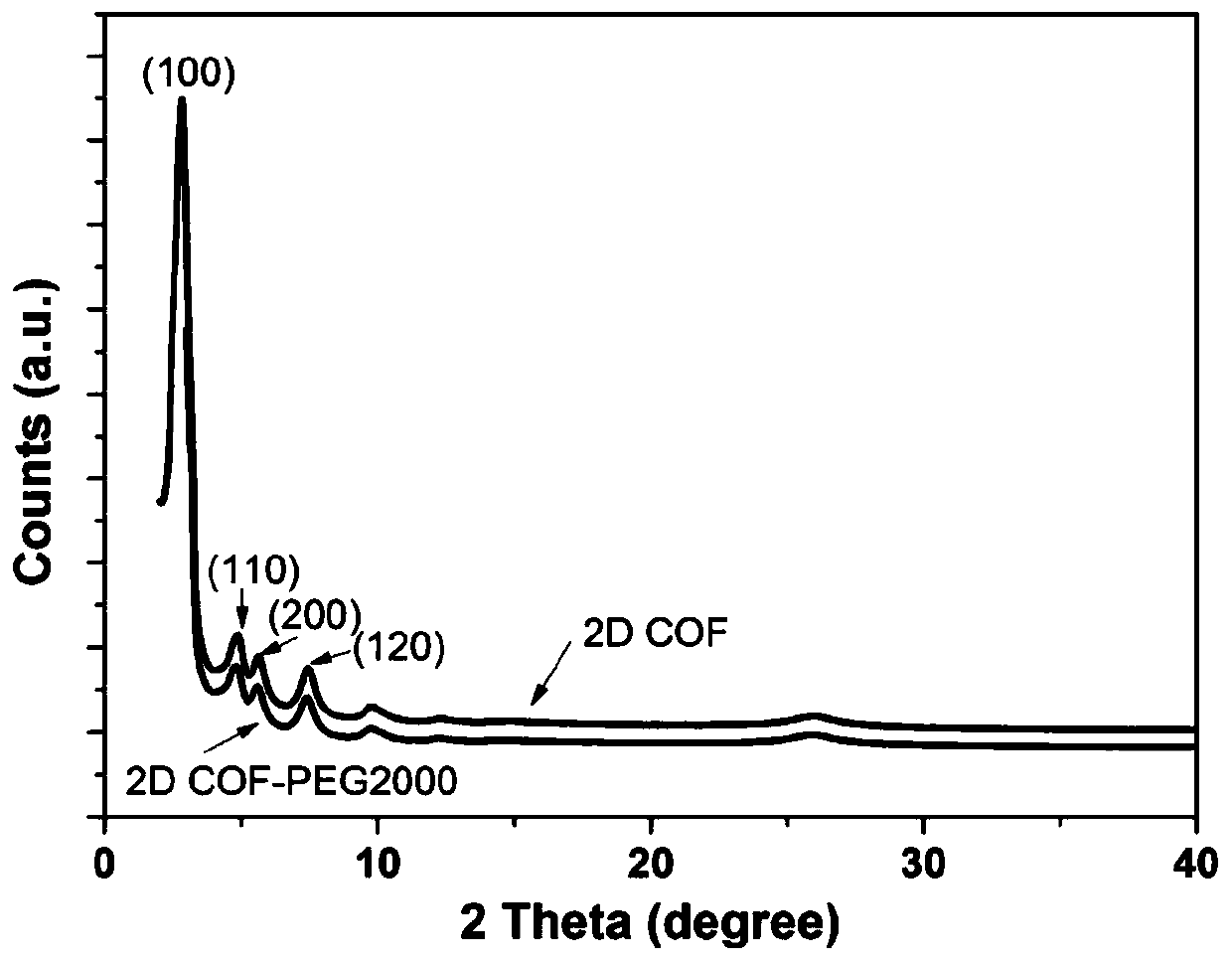

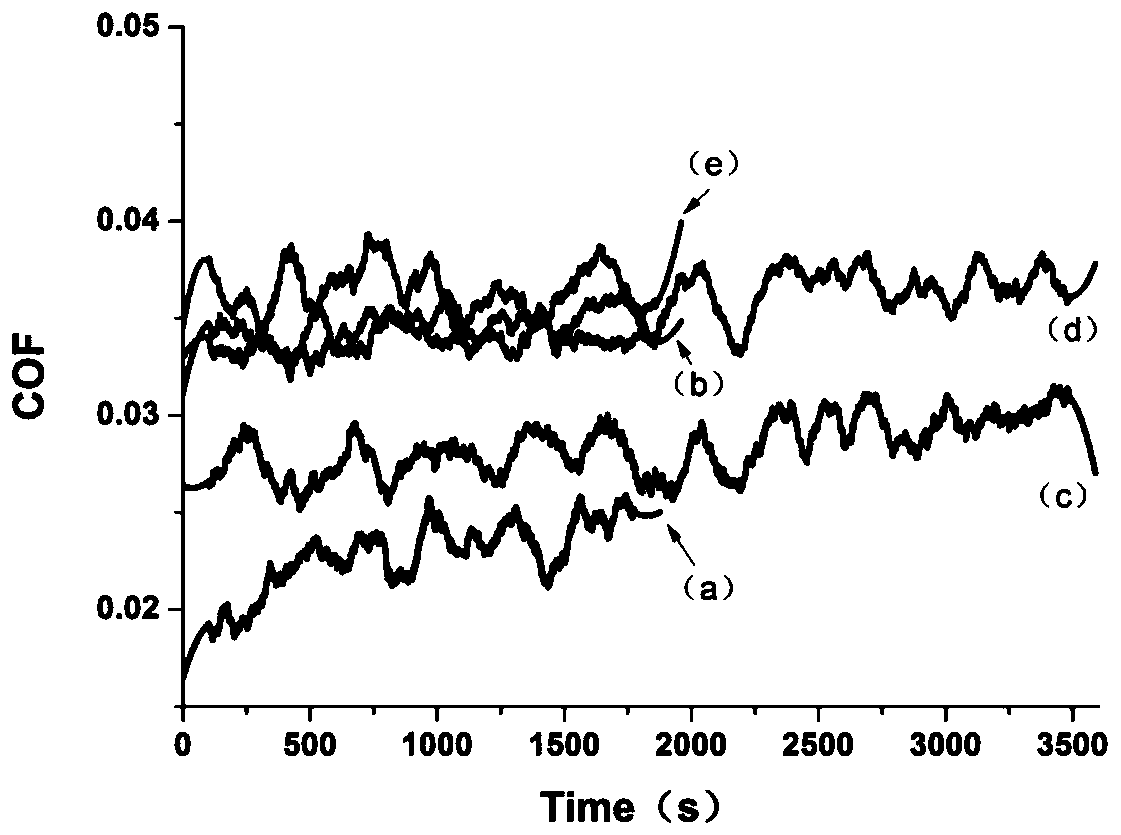

[0060] 3.544 grams (0.01mol) of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine and 2.492 grams (0.015mol) of 2,5-dihydroxyterephthalaldehyde were loaded into the reaction In the bottle, after three cycles of "freezing-pumping-gassing", fill it with high-purity nitrogen, seal the reaction bottle, put it in a blast drying oven at 120°C for 3 days to complete the polymerization reaction, and obtain the phenolic hydroxyl group 2D COF brown-red powder, dry weight 5.30 g, yield about 96%. figure 1 It is the XRD pattern of 2D COF, and the assignment of each crystal plane parameter shows that a 2D COF material with a two-dimensional layered structure has been obtained.

[0061] b. Post-functionalization of 2D COF grafted with PEG2000 to prepare 2D COF-PEG2000:

[0062] Weigh 1.0 g of 2D COF powder into a reaction bottle and add 10.0 g of solvent tetrahydrofuran, 0.01 g (0.057 mmol) of diethyl azodicarboxylate ...

Embodiment 2

[0070] a. Preparation of two-dimensional covalent organic framework (2D COF):

[0071] 3.544 grams (0.01mol) of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine and 2.492 grams (0.015mol) of 2,5-dihydroxyterephthalaldehyde were loaded into the reaction In the bottle, after three cycles of "freezing-pumping-gassing", fill it with high-purity nitrogen, seal the reaction bottle, put it in a blast drying oven at 120°C for 3 days to complete the polymerization reaction, and obtain the phenolic hydroxyl group 2D COF brown-red powder, dry weight 5.30 g, yield about 96%;

[0072] b. Post-functionalization of 2D COF grafted with PEG2000 to prepare 2D COF-PEG2000:

[0073]Weigh 1.0 g of 2D COF powder into a reaction bottle and add 25.0 g of solvent tetrahydrofuran, 0.45 g (2.58 mmol) of diethyl azodicarboxylate as a catalyst and 0.45 g (1.72 mmol) of triphenylphosphine, then weigh 35.0 g ( 17.5mmol) PEG2000 was added, stirred at room temperature for 36 hours to complete the etherification rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com