Preparation method of nitrogen-doped graphene/polytetrafluoroethylene (PTFE ) composite material

A technology of nitrogen-doped graphene and polytetrafluoroethylene, which is applied in the field of preparation of nitrogen-doped graphene/polytetrafluoroethylene composite materials, can solve the problems of easy deformation and poor wear resistance, and achieve good wear resistance , good friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

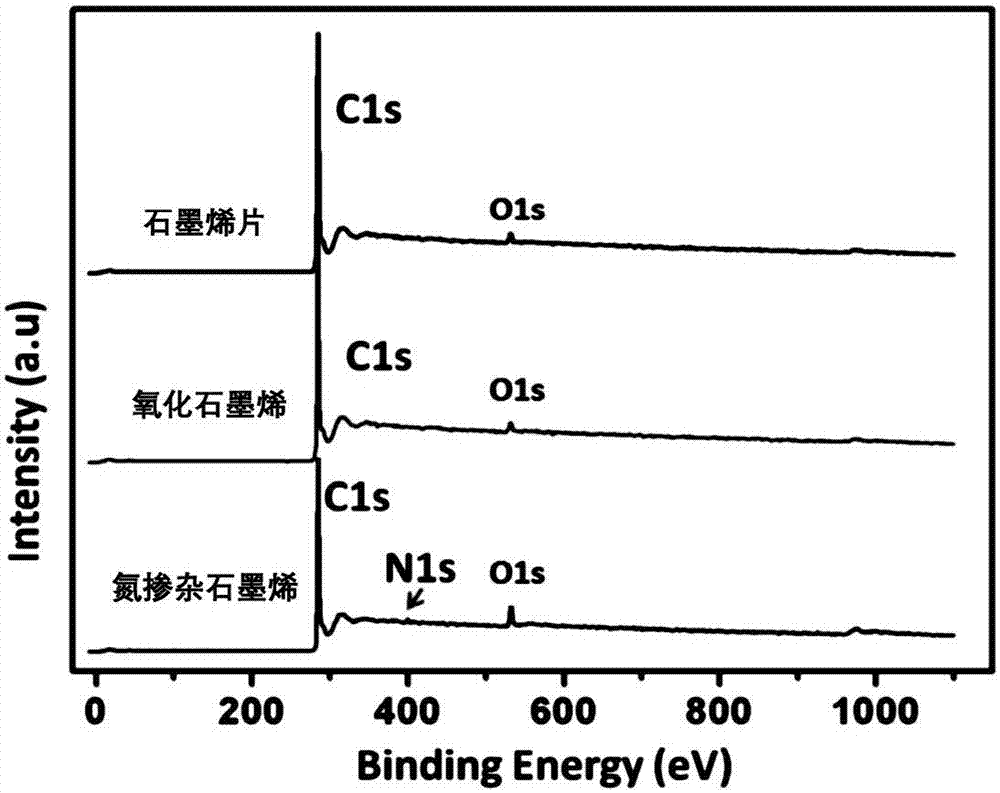

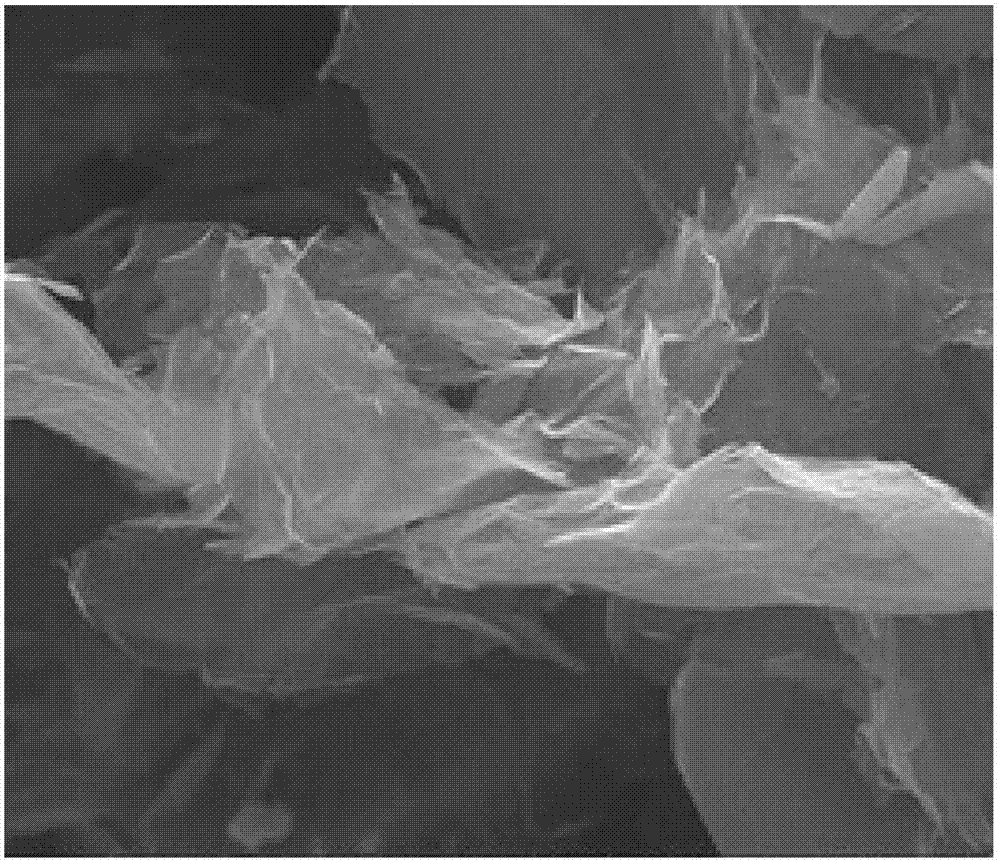

[0029]Example 1: Weigh 0.5 g of graphene sheet prepared by the re-expansion method, keep it in concentrated nitric acid at 120°C for 5 hours, then wash the solution to neutrality, and ultrasonically disperse the treated graphene into the aqueous solution again 1g of polyvinylpyrrolidone (PVP) was added, the solution was magnetically stirred, and the uniformly mixed solution was kept at a constant temperature of 100°C in the reaction kettle. After 4 hours, the sample was centrifuged and dried to obtain nitrogen-doped Graphene precursor material; will obtain the PTFE powder of nitrogen-doped graphene precursor material 0.5g and 100g and other auxiliary agents, auxiliary agent is the copper powder 5g of carbon fiber 1.5g, 100nm, 3mm glass fiber 1g, chlorinated 0.5g of copper, 0.2g of silane coupling agent (KH-550), 1g of nano-zinc oxide powder, and 0.5g of silicon carbide, and get a uniformly mixed powder through a mechanical mixer; then transfer the powder into a mold under a pre...

Embodiment 2

[0030] Example 2: Weigh 0.5g of graphene oxide prepared by the modified Hummer method, disperse it in an aqueous solution, then add 2g of glycine and heat it up to 140°C in the reactor, react for 4 hours and then centrifuge and dry to obtain Nitrogen-doped reduced graphene; then take nitrogen-doped reduced graphene 0.25g and PTFE powder of 100g and other additives, additives are 5 μm carbon fiber 1.4g, 1 μm copper powder 5g, 7mm glass fiber 1g, chlorine 0.6g of cuprous chloride, 0.25g of silane coupling agent (KH-560), 1.2g of nano-zinc oxide powder, and 0.8g of silicon carbide were mixed uniformly through a mechanical stirrer to obtain a mixed powder. Then the powder is transferred into a mold and slowly pressed under a pressure of 12Mpa, and then kept under constant pressure for 8 minutes to obtain a preform. Then put the preform into a temperature-controllable furnace from room temperature to 355°C and control the temperature rise rate to ~10°C / min. After reaching 355°C, ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com