Preparation method of polytetrafluoroethylene (PTFE) composite dielectric substrate

A composite medium and substrate technology, which is applied in the field of preparation of PTFE composite medium substrates for microwave circuits, can solve the problems of inability to guarantee complete removal of organic additives and moisture, complicated process flow, and high manufacturing costs, and is suitable for batch and large-scale production. Production, excellent comprehensive performance, easy coating and molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

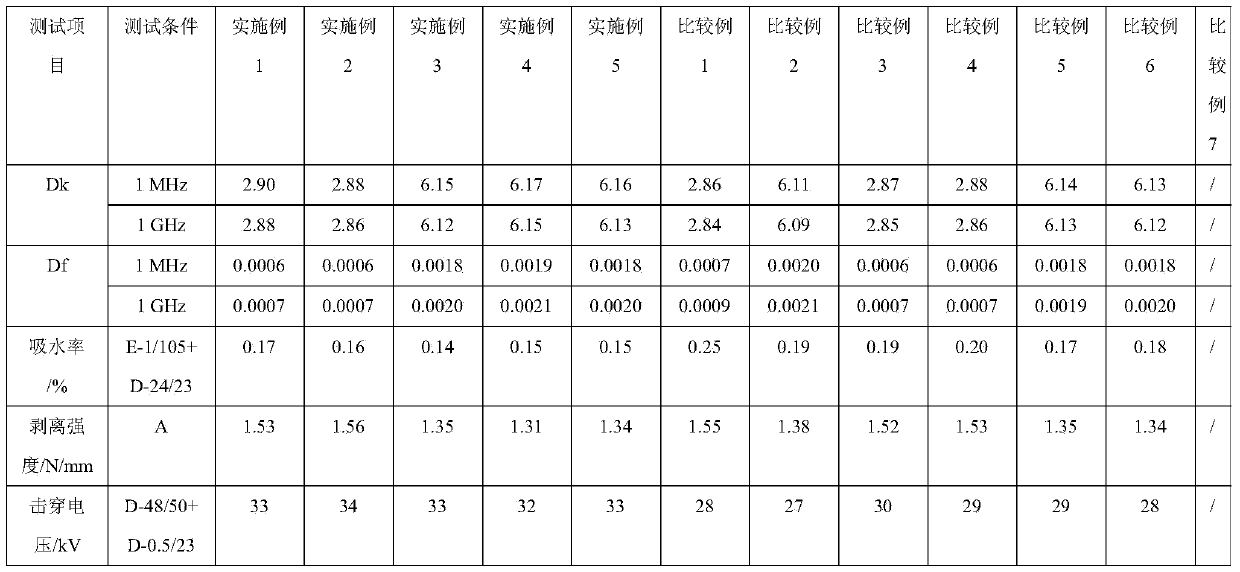

Examples

Embodiment 1

[0038] PTFE resin emulsion, particle size 0.25 μm, resin content 55wt%, produced by Japan Daikin Company, brand: D210C.

[0039] Inorganic filler: silicon micropowder, particle size about 1.5 μm, Sibelco Co., Ltd., brand name: MEGASIL525.

[0040] Thickener: polyoxyethylene distyrenated phenyl ether, Kao Corporation, brand name EMULGEN A-60.

[0041] Take 454.5g of the above-mentioned PTFE resin emulsion, add 250g of silicon micropowder, 4.0g of thickener, and carry out high-speed stirring and mixing for 2 hours. The viscosity of the test glue is 420mPa.s, and the viscosity is within the normal range.

[0042] The above-mentioned glue solution was coated on the surface of the copper foil with a coating machine, and a resin layer with a thickness of 255 μm was coated to obtain the glue-coated copper foil.

[0043]Put the coated copper foil in a vacuum oven at 100°C, bake for 1 hour to remove water, bake at 250°C for 1 hour to remove organic additives, bake at 350°C for 10 minu...

Embodiment 2

[0046] PTFE resin emulsion, particle size 0.25 μm, resin content 55wt%, produced by Japan Daikin Company, brand: D210C.

[0047] Inorganic filler: silicon micropowder, particle size about 1.5 μm, Sibelco Co., Ltd., brand name: MEGASIL525.

[0048] Thickener: polyoxyethylene distyrenated phenyl ether, Kao Corporation, brand name EMULGEN A-60.

[0049] Take 454.5g of the above-mentioned PTFE resin emulsion, add 250g of silicon micropowder, 4.0g of thickener, and carry out high-speed stirring and mixing for 2 hours. The viscosity of the test glue is 420mPa.s, and the viscosity is within the normal range.

[0050] The above-mentioned glue solution was coated on the surface of the copper foil with a coating machine, and a resin layer with a thickness of 104 μm was coated to obtain a glue-coated copper foil.

[0051] Put the coated copper foil in a vacuum oven at 100°C, bake for 1 hour to remove water, bake at 250°C for 1 hour to remove organic additives, bake at 350°C for 10 minut...

Embodiment 3

[0054] PTFE resin emulsion, particle size 0.25 μm, resin content 55wt%, produced by Japan Daikin Company, brand: D210C.

[0055] Inorganic filler: silicon micropowder, particle size about 1.5 μm, Sibelco Co., Ltd., brand: MEGASIL525; titanium dioxide, particle size about 0.25 μm, American Huntsman Company, brand: TR-28.

[0056] Thickener: polyoxyethylene distyrenated phenyl ether, Kao Corporation, brand name EMULGEN A-60.

[0057] Take 318g of the above-mentioned PTFE resin emulsion, add 60g of silica powder, 265g of titanium dioxide, and 5.2g of thickener for high-speed stirring and mixing for 2 hours. The viscosity of the test glue is 550mPa.s, which is within the normal range.

[0058] The above-mentioned glue solution was coated on the surface of the copper foil with a coating machine, and a resin layer with a thickness of 206 μm was coated to obtain a glue-coated copper foil.

[0059] Put the coated copper foil in a vacuum oven at 100°C, bake for 1 hour to remove water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com