Preparation method of PTFE composite nanofiltration membrane for water filtration purification

A composite nanofiltration membrane, filtration and purification technology, applied in the field of water treatment, can solve the problems of reduced membrane surface area, reduced rejection rate of nanofiltration membrane, and shedding of the intercepted layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

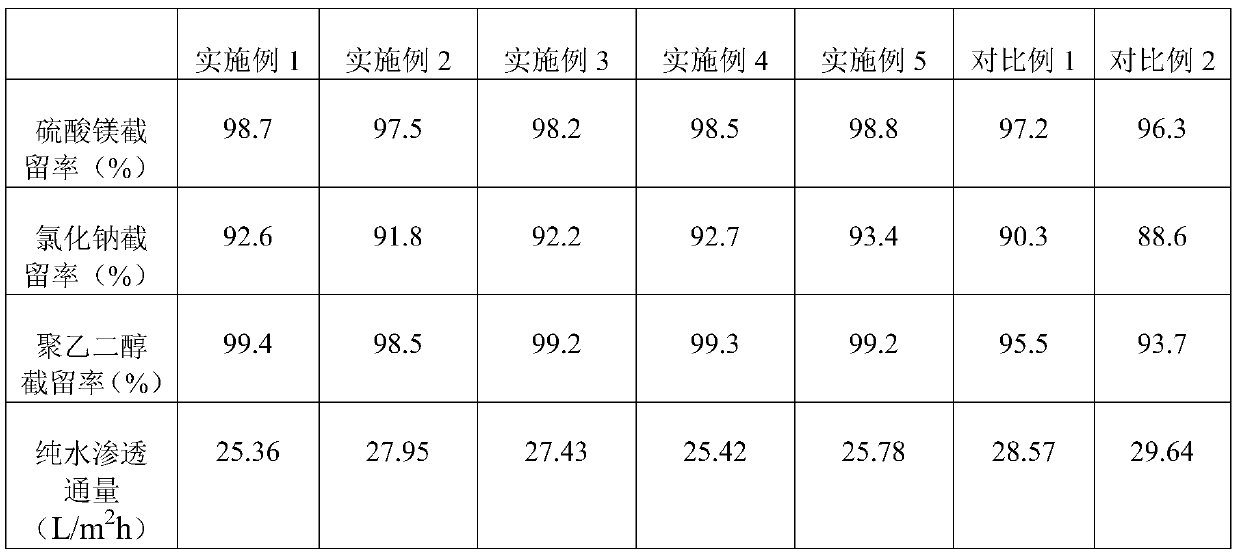

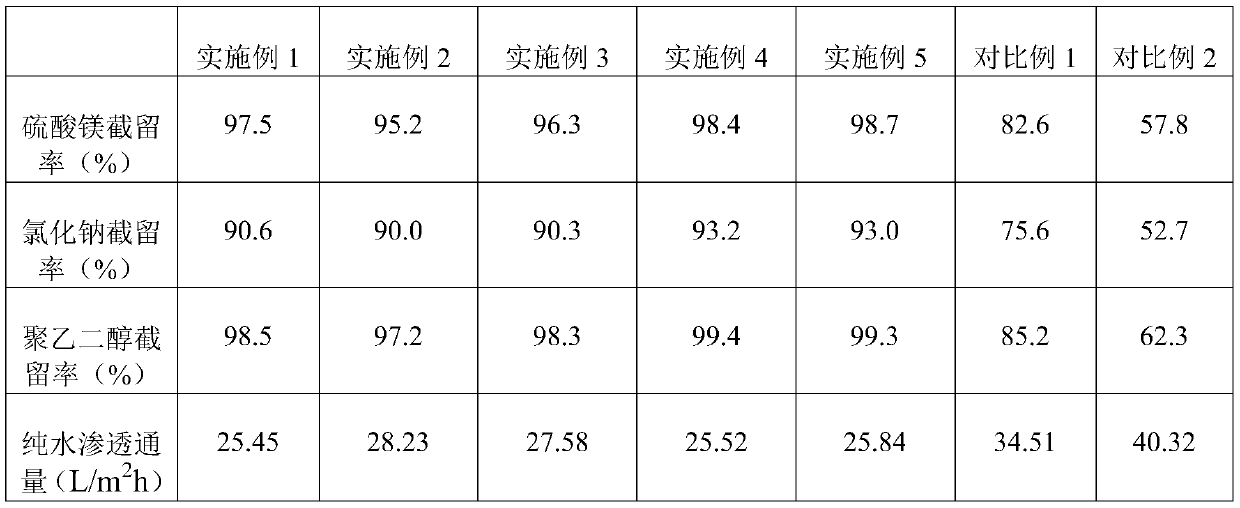

Examples

Embodiment 1

[0027] The preparation method of the PTFE composite nanofiltration membrane that is used for water filtration and purification comprises the following steps:

[0028]1) Get carboxymethyl chitosan and add it into deionized water and stir and dissolve, and be mixed with a carboxymethyl chitosan aqueous solution with a mass concentration of 5%; The ratio of mass ratio is 1:0.2, the hydrophobic polytetrafluoroethylene ultrafiltration base membrane is immersed in the carboxymethyl chitosan aqueous solution, soaked for 3h, after taking out, it is naturally dried to obtain the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane ;

[0029] 2) Take sodium alginate and add it into deionized water, stir and dissolve, and prepare a sodium alginate aqueous solution with a concentration of 3%;

[0030] According to the ratio of the mass ratio of the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane to sodium alginate of 1:0.25, the hydrophili...

Embodiment 2

[0037] The preparation method of the PTFE composite nanofiltration membrane that is used for water filtration and purification comprises the following steps:

[0038] 1) Get carboxymethyl chitosan and add in deionized water and stir and dissolve, and be mixed with a carboxymethyl chitosan aqueous solution with a mass concentration of 2%; The ratio of mass ratio is 1:0.4, the hydrophobic polytetrafluoroethylene ultrafiltration base membrane is immersed in the carboxymethyl chitosan aqueous solution, soaked for 2h, after taking it out, it is naturally dried to obtain the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane ;

[0039] 2) Take sodium alginate and add it into deionized water, stir and dissolve, and prepare a sodium alginate aqueous solution with a concentration of 6%;

[0040] According to the ratio of the mass ratio of the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane to sodium alginate of 1:0.3, the hydrophilic ...

Embodiment 3

[0047] The preparation method of the PTFE composite nanofiltration membrane that is used for water filtration and purification comprises the following steps:

[0048] 1) Get carboxymethyl chitosan and add in deionized water and stir and dissolve, and be mixed with a carboxymethyl chitosan aqueous solution with a mass concentration of 1%; The ratio of mass ratio is 1:0.1, the hydrophobic polytetrafluoroethylene ultrafiltration base membrane is immersed in the carboxymethyl chitosan aqueous solution, soaked for 5h, after taking it out, it is naturally dried to obtain the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane ;

[0049] 2) Take sodium alginate and add it into deionized water, stir and dissolve, and prepare a sodium alginate aqueous solution with a concentration of 5%;

[0050] According to the ratio of the mass ratio of the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane to sodium alginate of 1:0.2, the hydrophilic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com