Porous gas diffusion layer and preparation method thereof

A gas diffusion layer and diffusion hole technology, which is applied in electrical components, fuel cells, electrochemical generators, etc., can solve the problems of low porosity of porous gas diffusion layer, unfavorable gas diffusion, and low performance of metal-air batteries, so as to promote The process of commercialization, the preparation method is simple, and the effect of solving the sharp decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The embodiment of the present invention provides a method for preparing a porous gas diffusion layer of an air cathode of a metal-air battery, which includes the following steps:

[0014] Step S1: adding a pore former to the polytetrafluoroethylene (PTFE) emulsion to form a PTFE composite emulsion. The pore forming agent includes silicon oxide, calcium carbonate, aluminum oxide, titanium oxide or polystyrene microspheres. The particle size of the pore former is 0.05 μm-10 μm, and the particle size of the preferred pore former is 0.5 μm-5 μm. When the particle size of the pore former is larger than 10 μm, the pore size in PTFE is too large, which is not conducive to waterproofing. When the particle size of the pore former is smaller than 0.05 μm, the pore size in PTFE is too small, so that the PTFE The air permeability performance becomes worse.

[0015] The mass concentration of PTFE in the PTFE aqueous emulsion is 10%-60%, and the mass ratio of the pore former to the PTFE...

Embodiment 1 2

[0027] Example 1 Silica is used as a pore former to prepare a porous gas diffusion layer

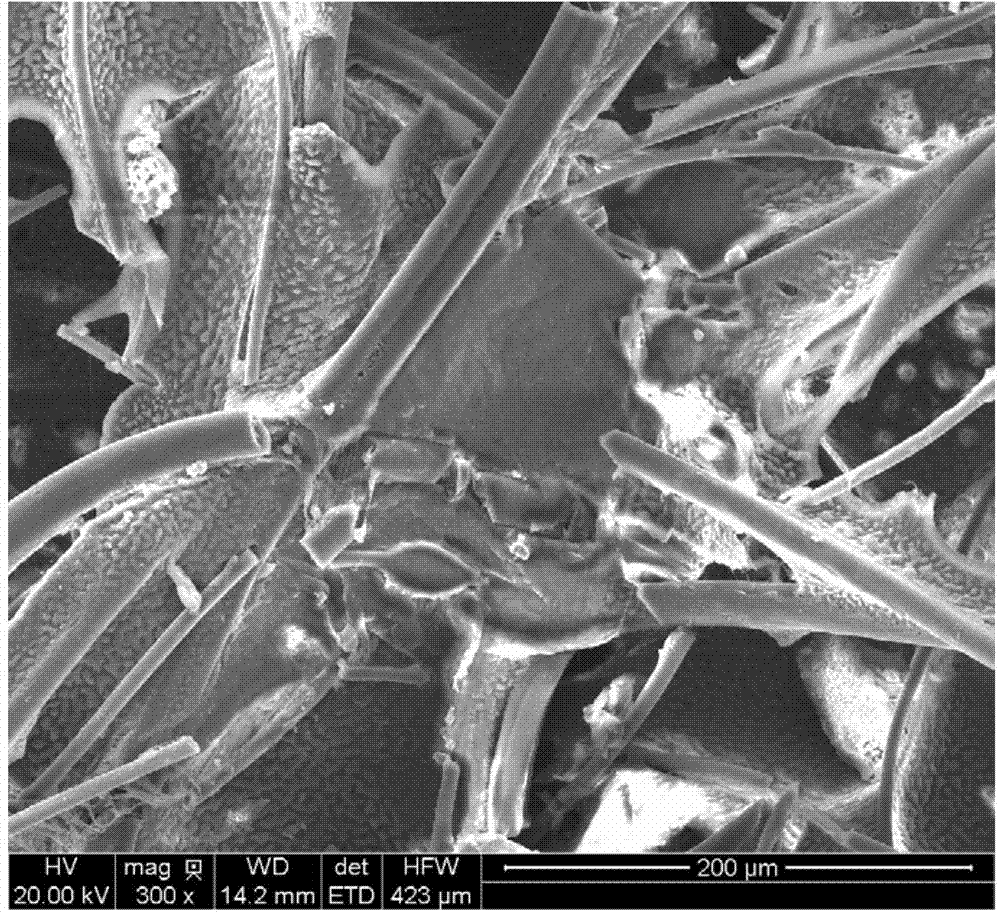

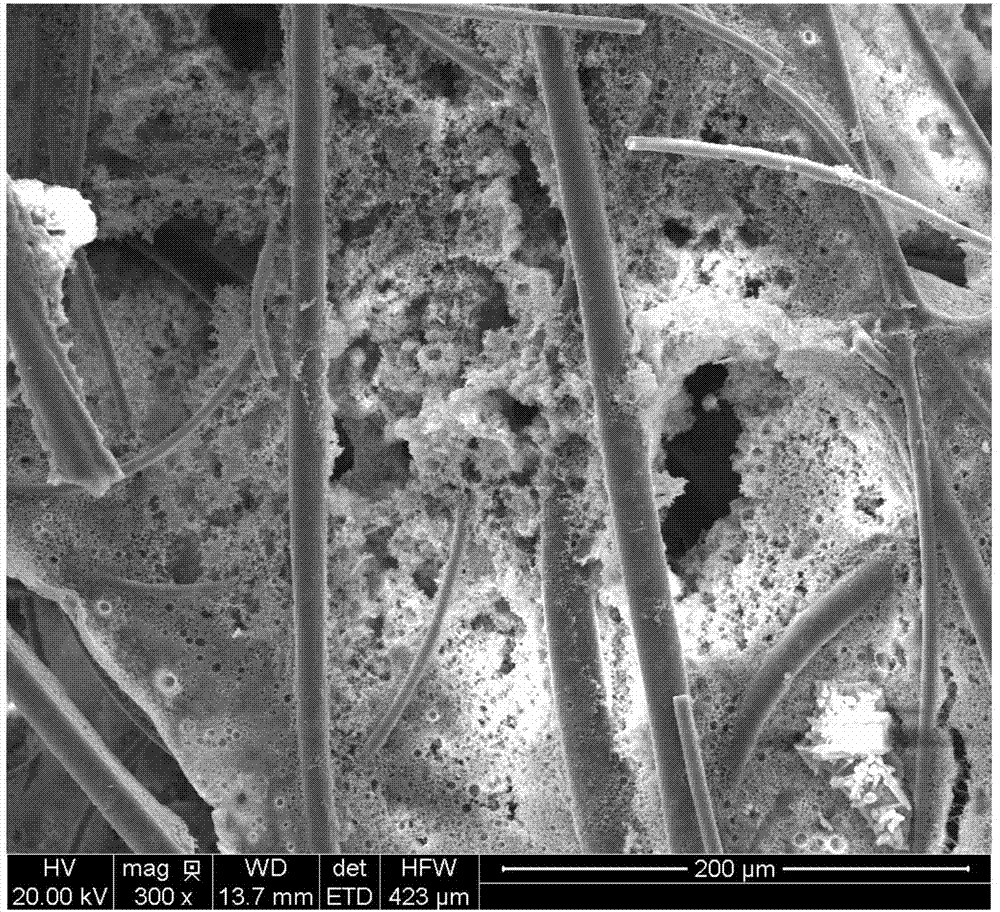

[0028] Choose a thickness of 4mm and a bulk density of 0.137g / cm 3 Conductive graphite felt, 30Wt.% PTFE solution and silica pore former with a particle size of 2μm as raw materials for the preparation of the porous gas diffusion layer;

[0029] The silica pore former with an average particle size of 2 μm is mixed with a 30 wt% PTFE solution, and then a composite emulsion is obtained by ultrasonic dispersion; wherein the mass percentage of the pore former and PTFE is 1:5 by mass percentage.

[0030] The composite emulsion is coated on the conductive support by two-step dipping to form a coated modified conductive support with a PTFE content of 60 wt.%. The coating modified conductive support is naturally dried at room temperature, and then fired at 350° C. for 60 minutes, and then processed at a pressure of 8 MPa.

[0031] Then the sintered coating modified conductive support is immersed and etc...

Embodiment 2 2

[0032] Example 2 Silica is used as a pore former to prepare a porous gas diffusion layer

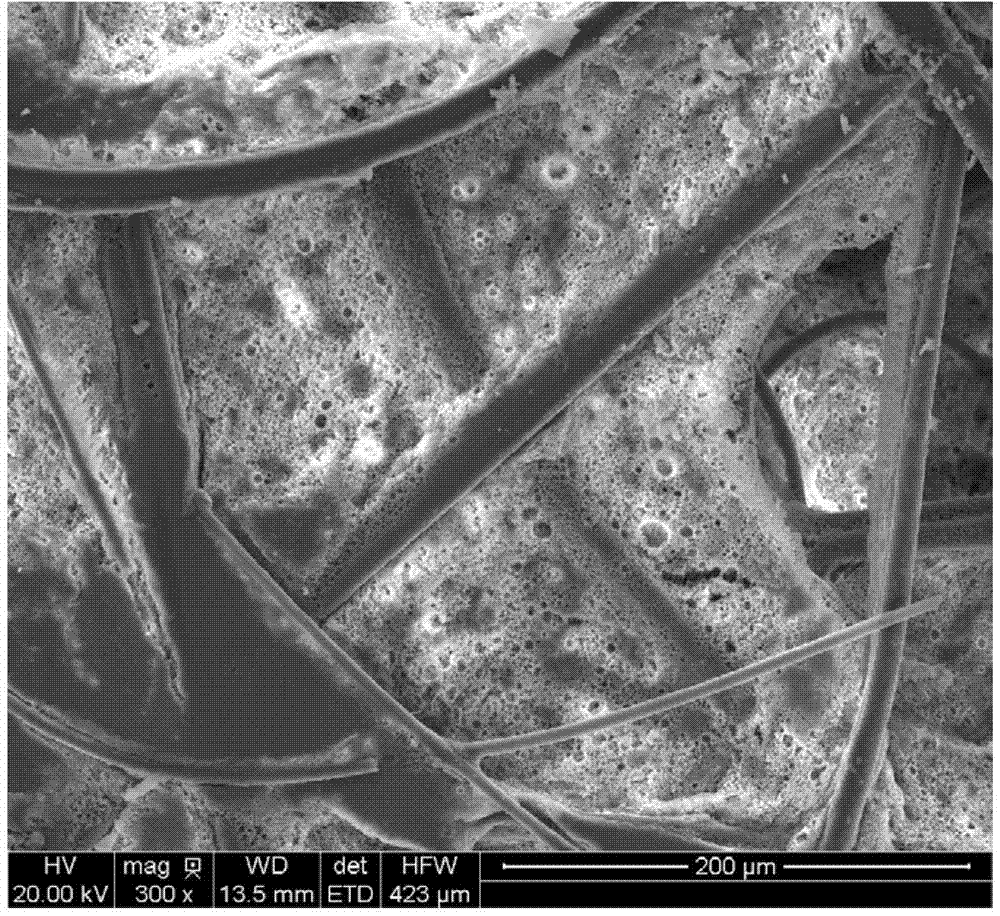

[0033] Choose a thickness of 6mm and a bulk density of 0.095g / cm 3 Conductive carbon fiber felt, 40Wt% PTFE solution and silica pore former with a particle size of 2.5μm are used as raw materials for the preparation of the porous gas diffusion layer;

[0034] The silica pore former with an average particle size of 2.5 μm is mixed with a 40 wt% PTFE solution, and then a composite emulsion suitable for application is obtained by mechanical stirring. Among them, calculated by mass percentage, the mass percentage of pore former and PTFE is 1:1.

[0035] The composite emulsion is sprayed on the conductive support to form a coating modified conductive support with a PTFE content of 55wt.%. Dry the above-mentioned coated modified conductive support at 50°C, then fire it at 330°C for 30 minutes, and then treat it under a pressure of 10MPa.

[0036] Then the sintered coating modified conductive support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com