High-frequency glue-free double-sided flexible copper clad laminate and preparation method thereof

A flexible copper-clad laminate, double-sided technology, applied in the field of high-frequency glue-free double-sided flexible copper-clad laminate and its preparation, can solve the problems of reducing material water absorption, low water absorption, and insufficient dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

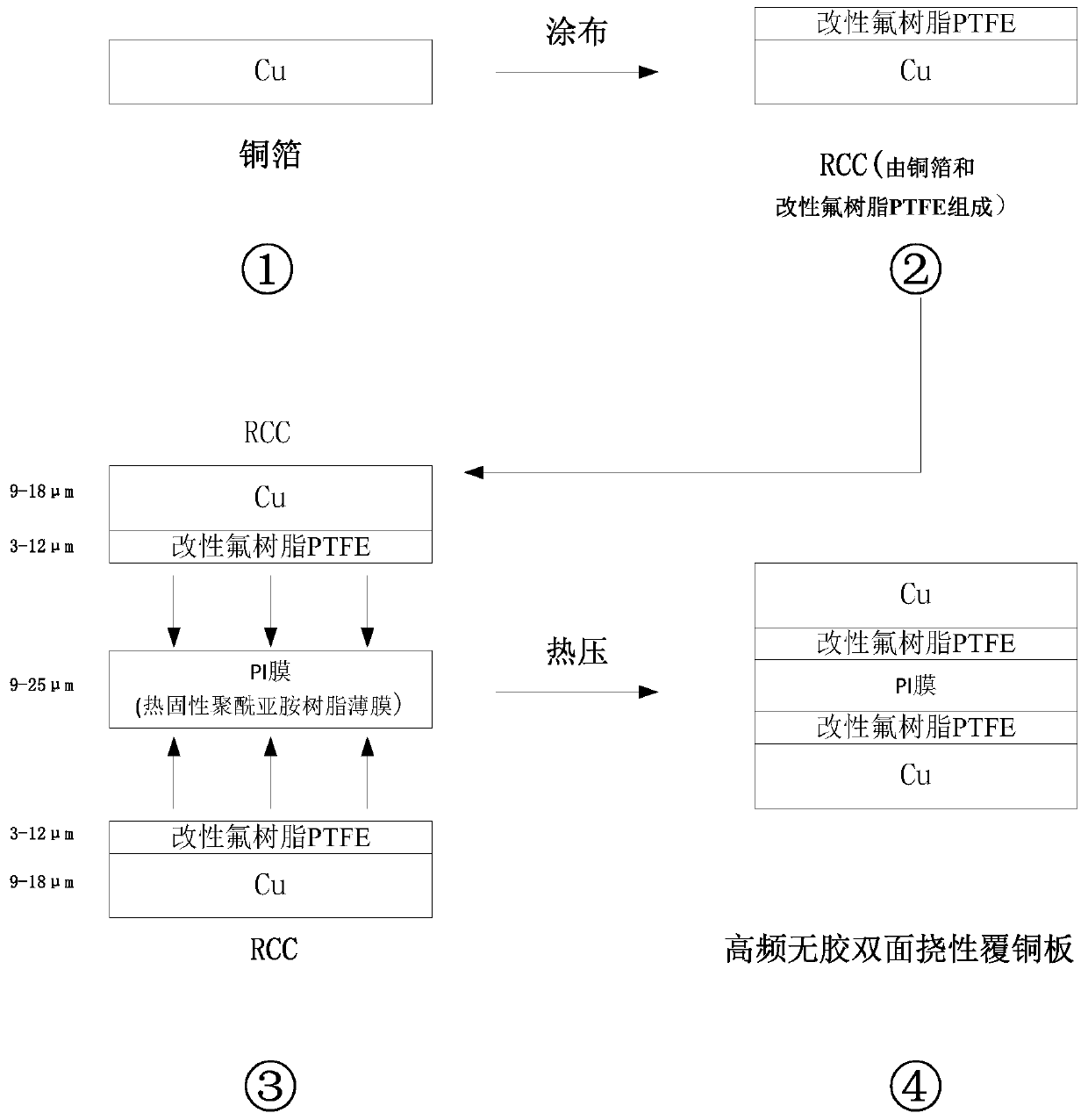

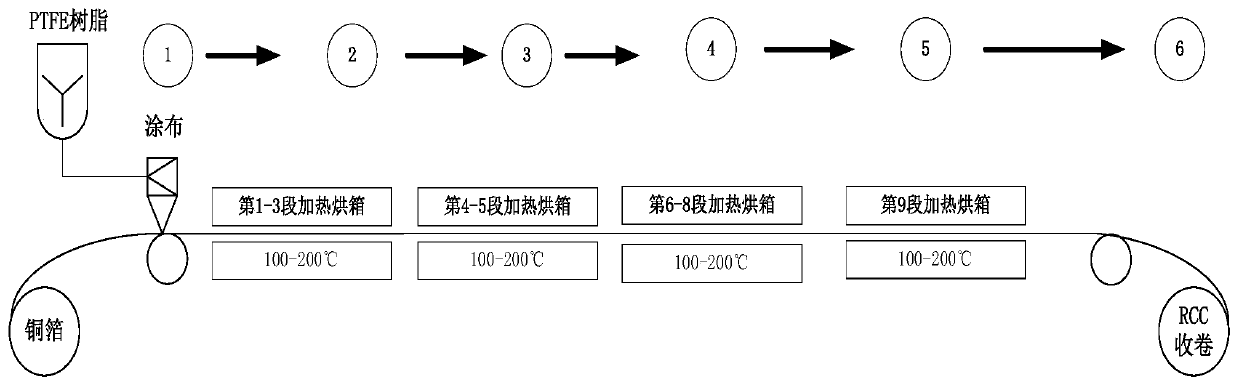

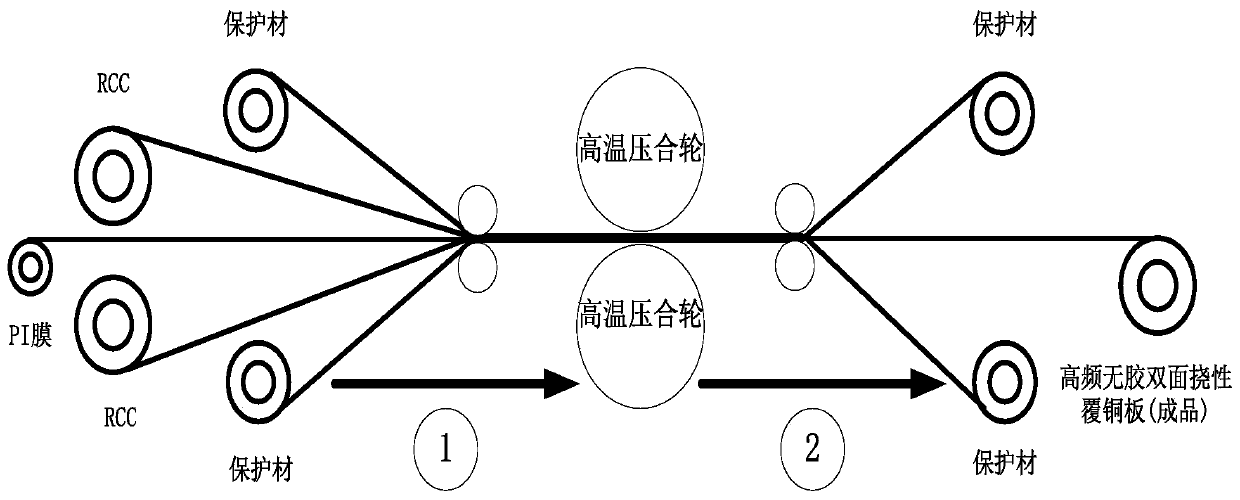

[0045] A high-frequency adhesive-free double-sided flexible copper clad laminate, including upper and lower layers of copper foil and an insulating layer sandwiched between the two layers of copper foil: the insulating layer is made of a thermosetting polyimide resin film in the middle and a thermosetting PTFE / PI / PTFE composite film composed of modified fluororesin PTFE on the upper and lower sides of polyimide resin film PI.

[0046] The thickness of the PTFE / PI / PTFE composite film is 25 μm.

[0047] The preparation method of modified fluororesin PTFE comprises the following steps:

[0048] S1) raw material preparation: prepare modified PTFE powder;

[0049] S2) solvent selection: select the organic solvent MEK;

[0050] S3) additive selection: select fluorine surfactant as additive;

[0051]S4) Synthesis of modified fluororesin PTFE: add 45-50%wt modified PTFE powder to the selected organic solvent, add fluorosurfactant at the same time, stir for 2 hours, then add 10-20%w...

Embodiment 2

[0063] A high-frequency adhesive-free double-sided flexible copper clad laminate, including upper and lower layers of copper foil and an insulating layer sandwiched between the two layers of copper foil: the insulating layer is an LCP (liquid crystal polymer) film, and the thickness of the LCP film is is 50 μm.

[0064] The preparation method is as follows: first make the LCP into a film, and then press the upper and lower layers of copper foil through a hot press to form a high-frequency adhesive-free double-sided flexible copper clad laminate with a structure of CU / LCP / CU.

Embodiment 3

[0066] A high-frequency adhesive-free double-sided flexible copper clad laminate, including upper and lower layers of copper foil and an insulating layer sandwiched between the two layers of copper foil: the insulating layer is a modified MPI (thermoplastic polyimide) film, and the MPI film The thickness is 50 μm.

[0067] The preparation method is as follows: first make MPI into a film shape, and then press it against the upper and lower layers of copper foil through a hot press to form a high-frequency adhesive-free double-sided flexible copper-clad laminate with a structure of CU / MPI / CU.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com