Preparation method of hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane

A technology of polytetrafluoroethylene and microporous membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a hydrophilic polytetrafluoroethylene composite microporous membrane, the specific steps are as follows:

[0037] 1) Take polytetrafluoroethylene powder with a mass ratio of 50%, 40% solvent oil, and 10% nano-alumina particles. PTFE / Al was prepared after calendering, longitudinal drawing, heat treatment and transverse drawing 2 o 3 Composite microporous membrane;

[0038] 2) Add diethanolamine and silane coupling agent to water to form a modified aqueous solution, place the PTFE composite microporous membrane obtained in step 1) in ethanol until it becomes transparent, then immerse it in the modified aqueous solution, and carry out the surface treatment at room temperature. Take out and dry after coating for 60 minutes; the mass concentration of diethanolamine in the modified aqueous solution is 5%, and the mass concentration of silane coupling agent is 0.5%;

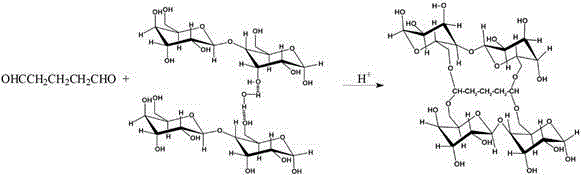

[0039] 3) Immerse the dried PTFE composite microporous membrane into glutaraldehyde...

Embodiment 2

[0041] A preparation method of a hydrophilic polytetrafluoroethylene composite microporous membrane, the specific steps are as follows:

[0042] 1) Measure polytetrafluoroethylene powder with a mass ratio of 60%, 35% solvent oil, and 5% nano-titanium dioxide particles, and mix them evenly in a "V"-shaped mixer. PTFE / TiO was prepared after drawing, heat treatment and horizontal drawing 2 Composite microporous membrane;

[0043] 2) Add polyvinyl alcohol and silane coupling agent to water to form a modified aqueous solution, soak the PTFE composite microporous membrane obtained in step 1) in ethanol until it becomes transparent, then immerse it in the modified aqueous solution, and perform surface treatment at room temperature After coating for 30 minutes, take it out and dry it; the mass concentration of polyvinyl alcohol in the modified aqueous solution is 10%, and the mass concentration of silane coupling agent is 0.2%;

[0044] 3) Immerse the dried PTFE composite microporou...

Embodiment 3

[0046] A preparation method of a hydrophilic polytetrafluoroethylene composite microporous membrane, the specific steps are as follows:

[0047] 1) Measure polytetrafluoroethylene powder with a mass ratio of 70%, 28% solvent oil, and 2% nano-silicon dioxide particles, and mix them evenly in a "V" type mixer. PTFE / SiO was prepared after longitudinal drawing, heat treatment and transverse drawing 2 Composite microporous membrane;

[0048] 2) Add polyvinyl alcohol and silane coupling agent to water to form a modified aqueous solution, soak the PTFE composite microporous membrane obtained in step 1) in ethanol until it becomes transparent, then immerse it in the modified aqueous solution, and perform surface treatment at room temperature Take out and dry after coating for 90 minutes; the mass concentration of polyvinyl alcohol in the modified aqueous solution is 1%, and the mass concentration of silane coupling agent is 0.5%;

[0049] 3) Immerse the dried PTFE composite micropor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com