Engine cooling system

An engine cooling and engine block technology, applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of poor lubrication effect, waste of energy efficiency, low temperature of gearbox gear oil, etc., to avoid the temperature of gearbox gear oil. too low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

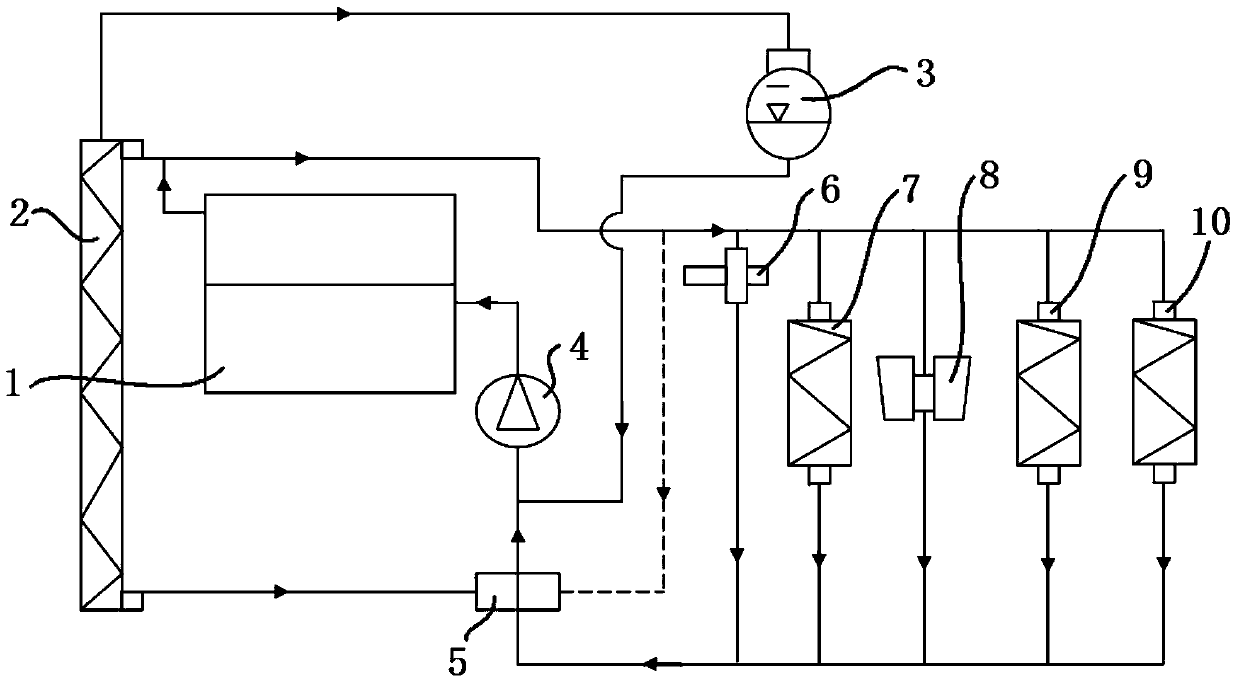

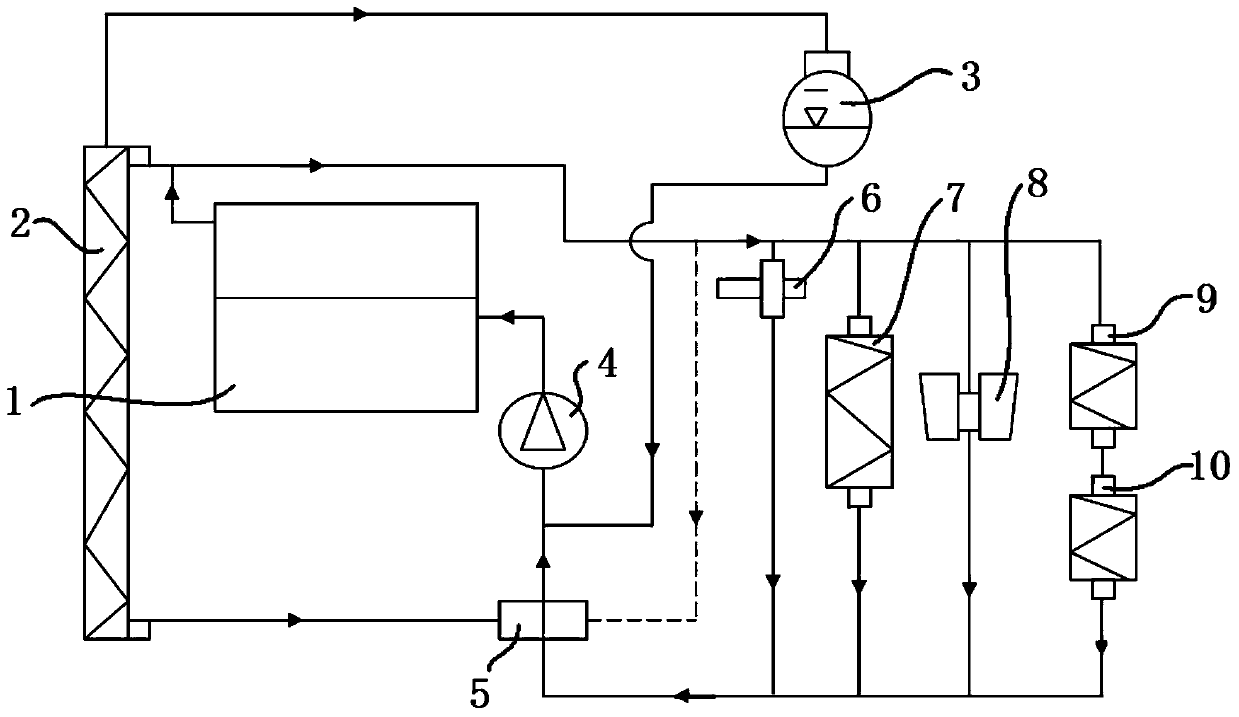

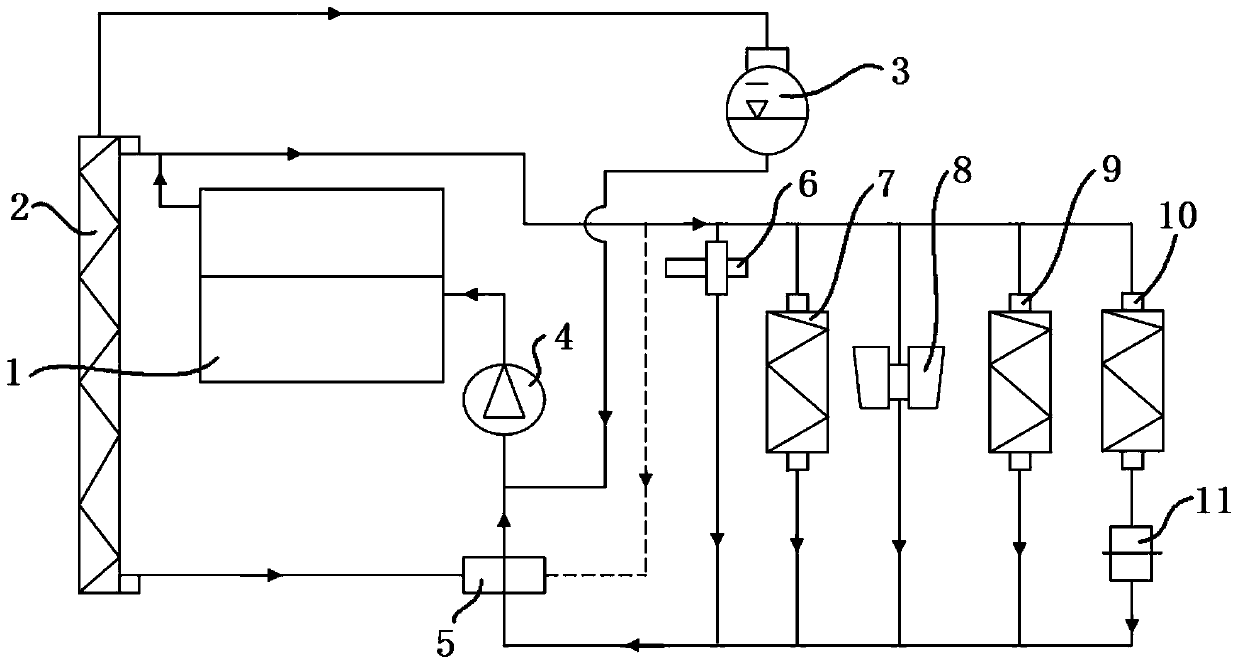

[0059] refer to figure 1 with figure 2 , respectively show the structural diagrams of the traditional parallel and series engine cooling systems, the difference between these two engine cooling systems is only the connection mode of the heater 9 and the gearbox cooler 10, both of these two engine cooling systems include cooling The liquid pump 4, the water jacket arranged in the cylinder block and cylinder head of the engine 1, the first thermostat 5, the radiator 2 and the gearbox cooler 10. Wherein, the circulation circuit of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com