Copper Alloy for Heat Exchanger Tube

a heat exchanger tube and copper alloy technology, applied in the field of copper alloys, can solve the problems of increasing the weight of the tube and therefore the material cost associated with the tube, and achieve the effects of good thermal conductivity, high tensile strength, and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

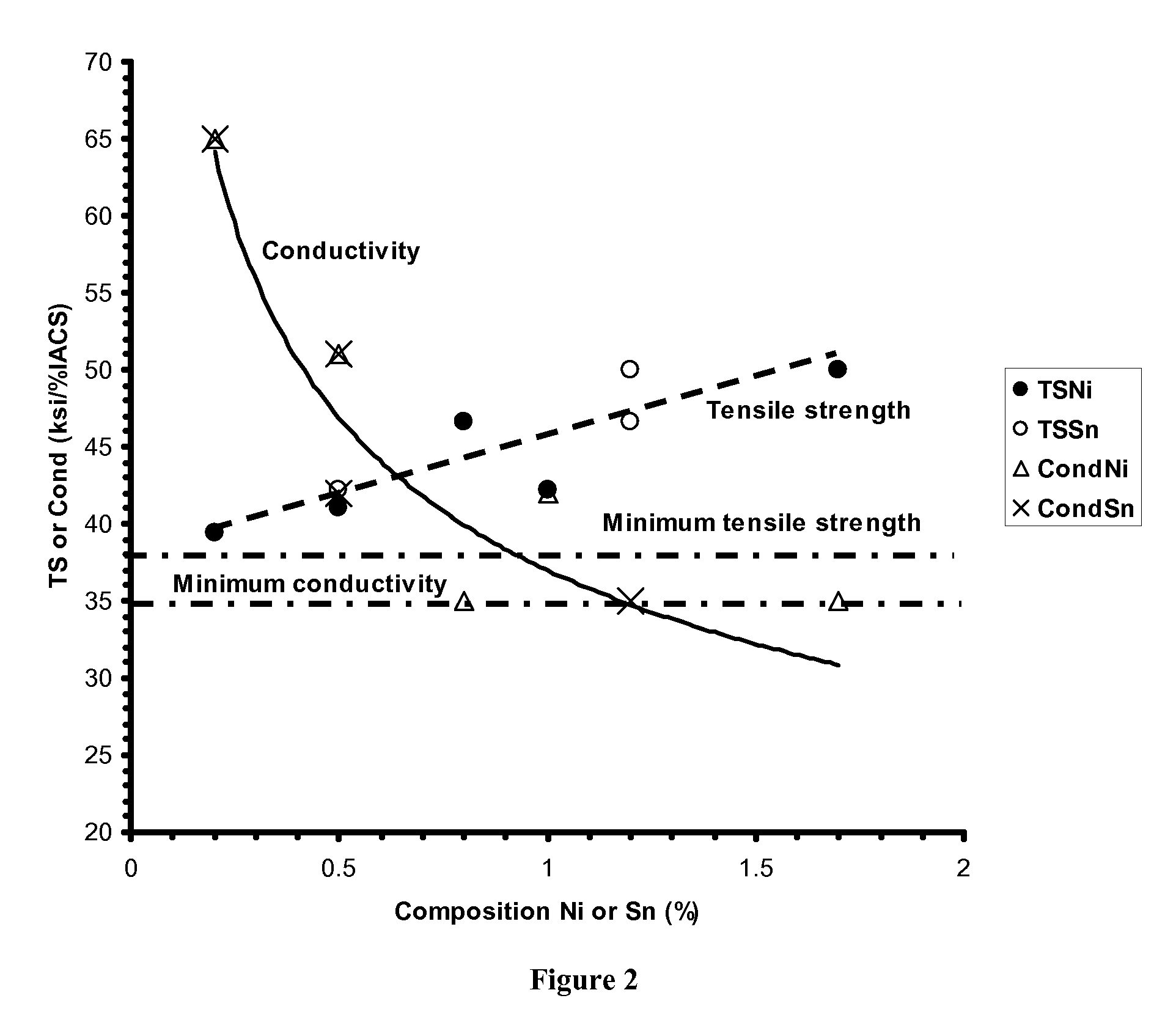

[0039]Copper alloys with different Ni and Sn contents were produced in pilot scale and mechanical and physical properties tested, see Table 1.

[0040]The results was plotted versus the amount of Ni or Sn, see FIG. 2. All tested alloys meet a desired minimum conductivity of 35% IACS. The mechanical properties of a minimum tensile strength of 38 ksi is achieved for all tested alloys. In order to meet desired strength and conductivity the composition should be from 0.2% to 1.0% by weight for both Ni and Sn.

[0041]Material of a composition of 0.5% Ni and 0.5% Sn (CuNi(0.5)Sn(0.5) was produced in full production scale and formed to tubes using the roll and weld method. The tubes were produced both in standard wall thickness (e.g., 0.0118 inches) and with 13% lower wall thickness. Mechanical properties of the tubes were tested using ASTM and UL (e.g., UL testing protocols and compared with tubes made of “present use” copper alloy C12200 with standard wall thickness. The results are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com