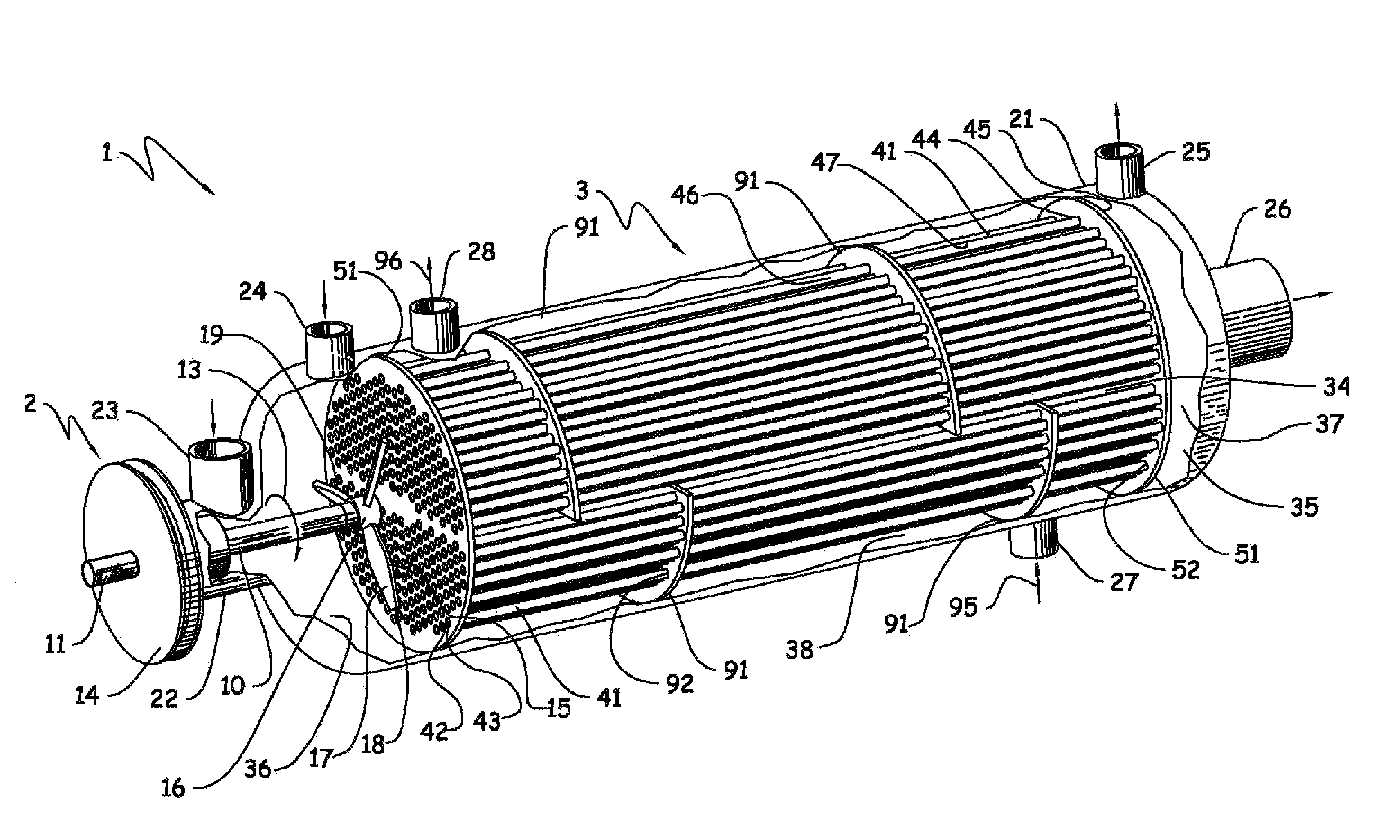

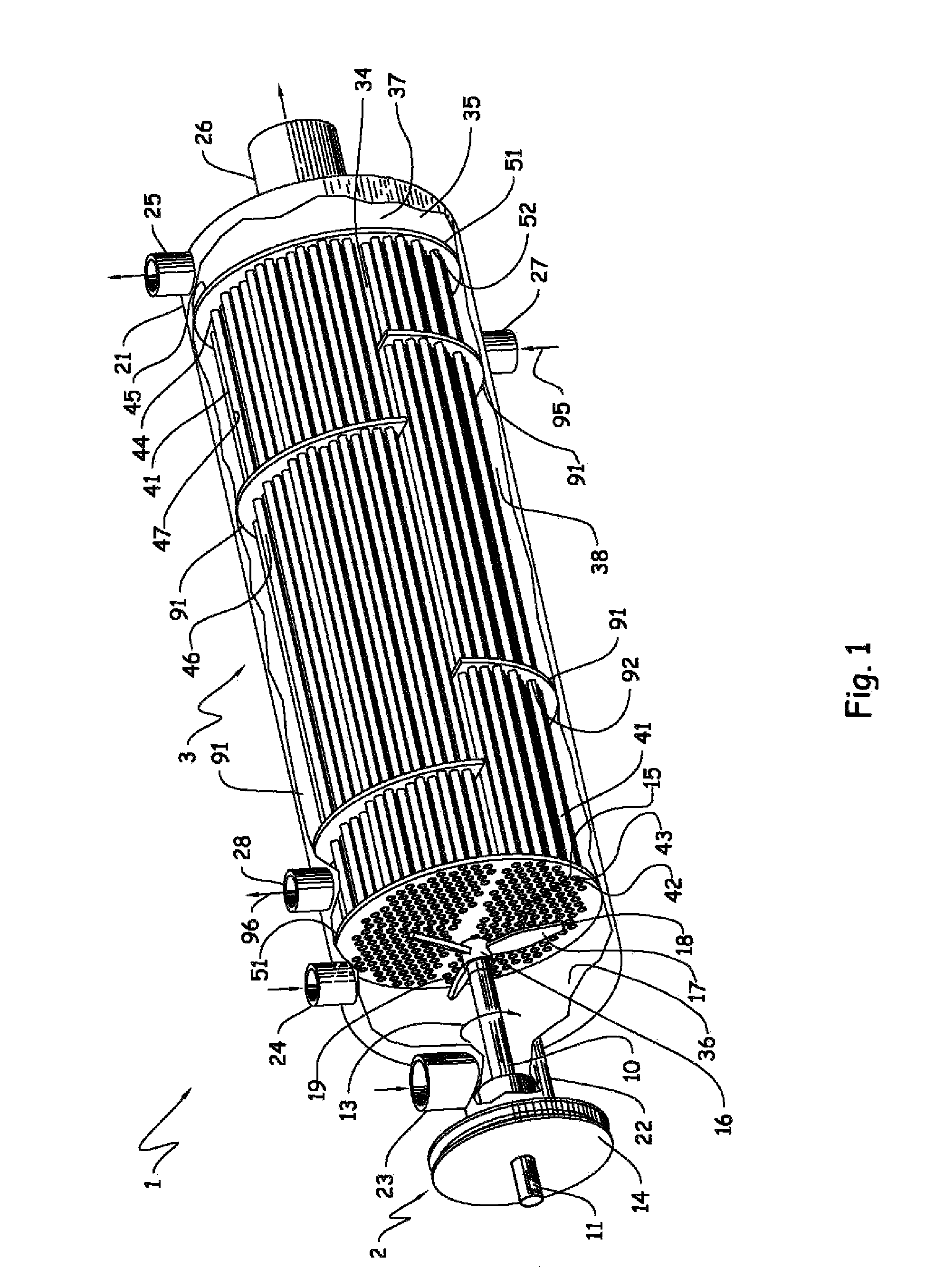

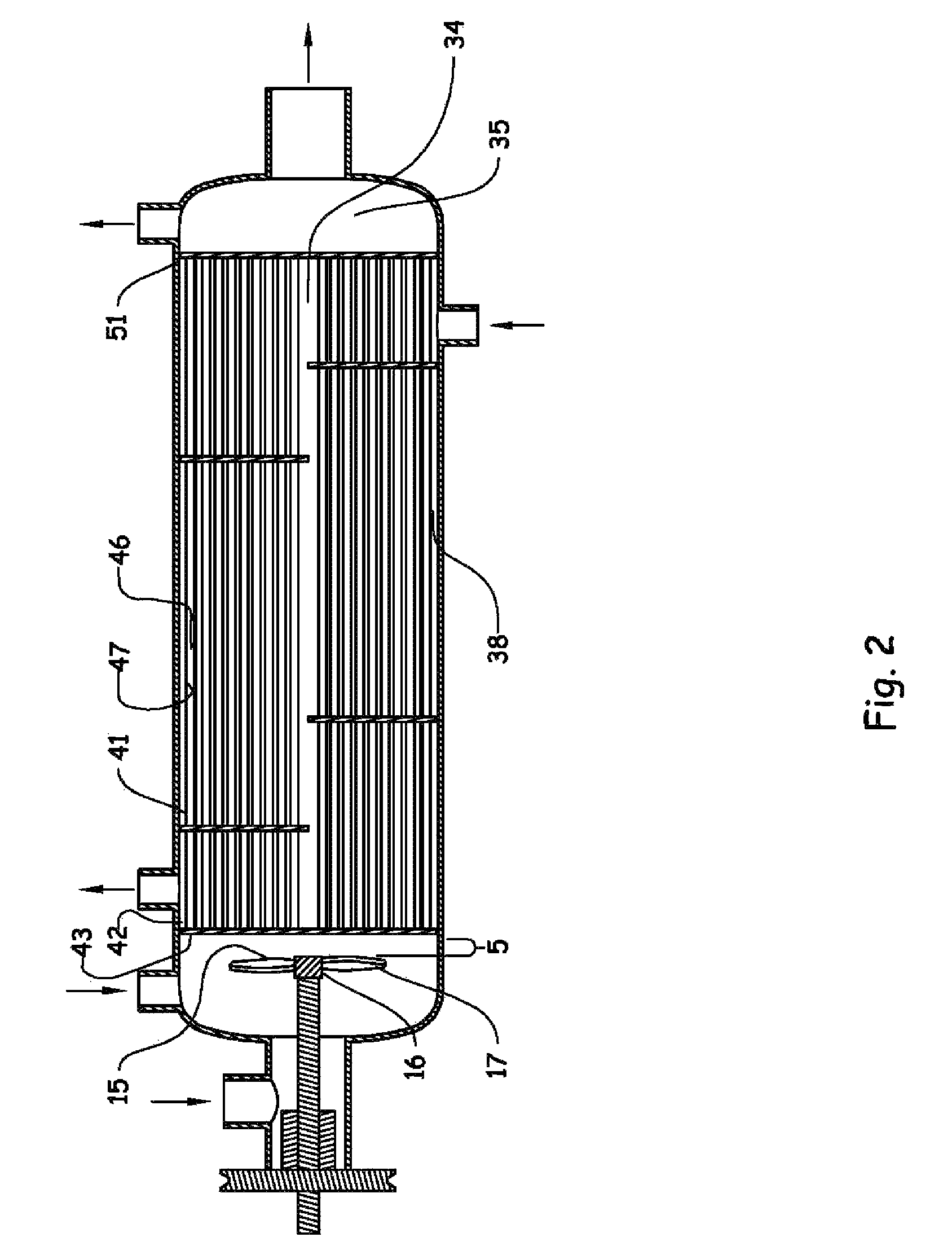

Tube-side sequentially pulsable-flow shell-and-tube heat exchanger appratus, system, and method

a heat exchanger and sequential pulsable flow technology, applied in indirect heat exchangers, chemical/physical/physicochemical processes, and tube reactors, etc., can solve the problems of increased likelihood of heterogeneous materials, work by, and lack of pulsed flow capability of shell and coil heat exchangers, etc., to improve heat exchange rates, reduce fouling, and improve heat exchange rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Simulated Operation of and Calculated Data for Simulated Heat Exchanger Apparatus

[0110]The simulated heat exchanger apparatus has 3.627 meters long tubes, each tube having an inner diameter of 0.0148 meters (14.8 millimeters). To increase computational efficiency, however, only a 0.406 meter (16 inches) long portion of the tubes are directly simulated, leaving a 3.221 meter long truncated portion of the tubes that will be indirectly simulated using a method described in the next paragraph. FIG. 4 shows geometry and dimensions of a portion of the simulated heat exchanger apparatus.

[0111]The portion of the simulated heat exchanger apparatus of FIG. 4 is simulated using the Computational Fluid Dynamics (“CFD”) computer software package FLUENT® 6.3.26, a product of ANSYS Inc., 275 Technology Drive, Canonsburg, Pa., U.S.A. Before performing the simulation, a computational domain that has the same geometry and dimensions as the simulated heat exchanger apparatus is built and discretized i...

example 2

Pilot Heat Exchanger System Design and Testing

[0116]Setup: All tests are conducted using a pilot heat exchanger system comprising a shell-and-tube heat exchanger, centrifugal pump (for pumping slurry), 3 sections of tubing, agitatable feed tank (for holding a slurry in an agitated state), two stirrer motors, first rotatable stir shaft, first impeller, and support structures. A photographic system is also employed. The shell-and-tube heat exchanger comprises an open-ended glass cylinder, inlet and outlet headers, 7 tubes, inlet and outlet tube sheets, second rotatable stir shaft, and second impeller. The open-ended glass cylinder has an inside diameter that is 4 inches (10.2 centimeter (cm)) and a length of 35 inches (88.9 cm) and comprises a portion of the shell of the shell-and-tube heat exchanger. The open ends of the glass cylinder are inlet and outlet ends. Each of the seven tubes is disposed horizontally and substantially parallel to each other. Each of the seven tubes is ⅜ inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com