Cooler

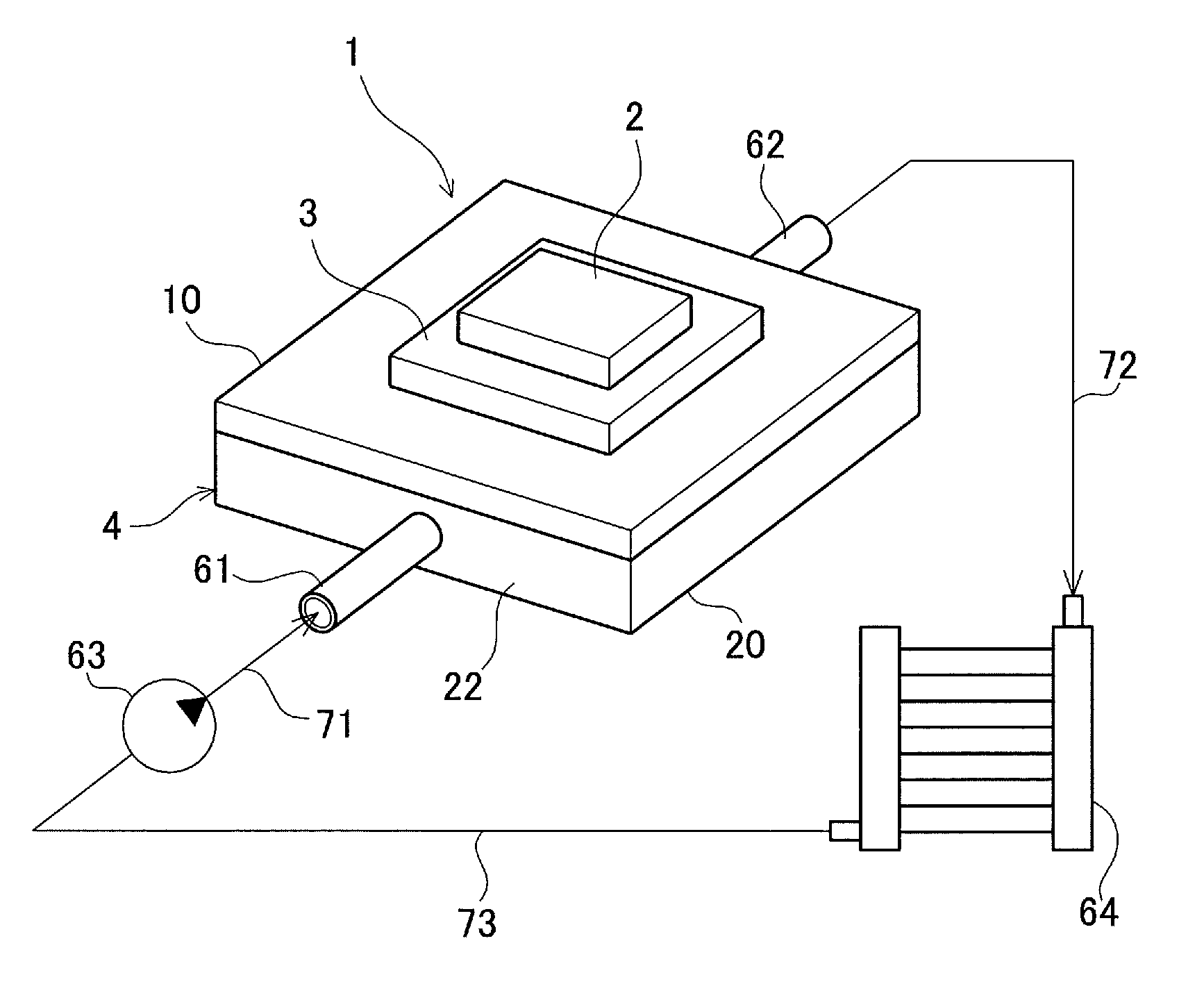

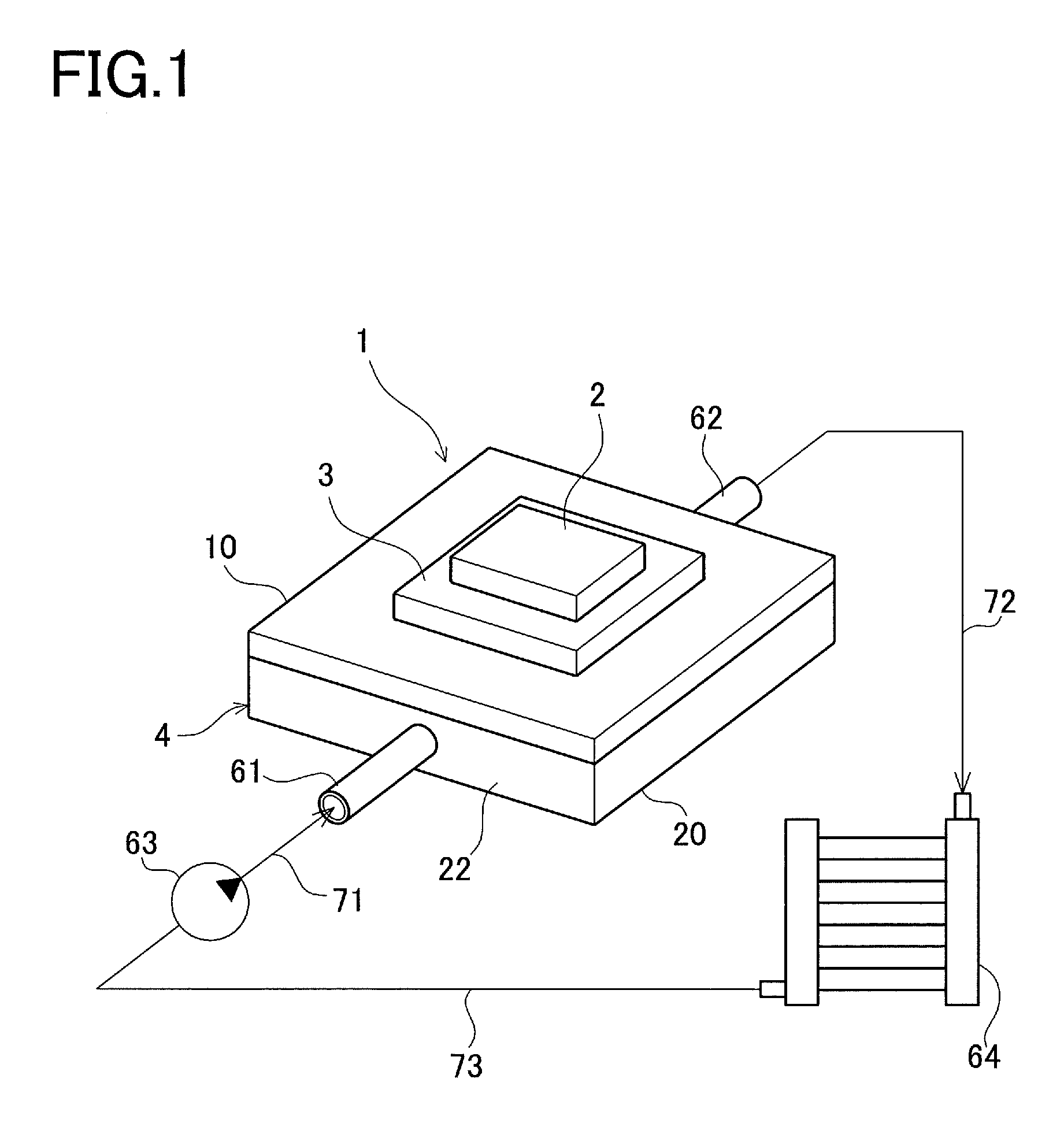

a cooling device and cooling fin technology, applied in the field of cooling devices, can solve the problems of increasing the amount of heat generated by semiconductor devices, and achieve the effects of enhancing cooling performance, preventing stagnation of coolant near the lowered curved portion, and improving the heat transfer coefficient of the wavy fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

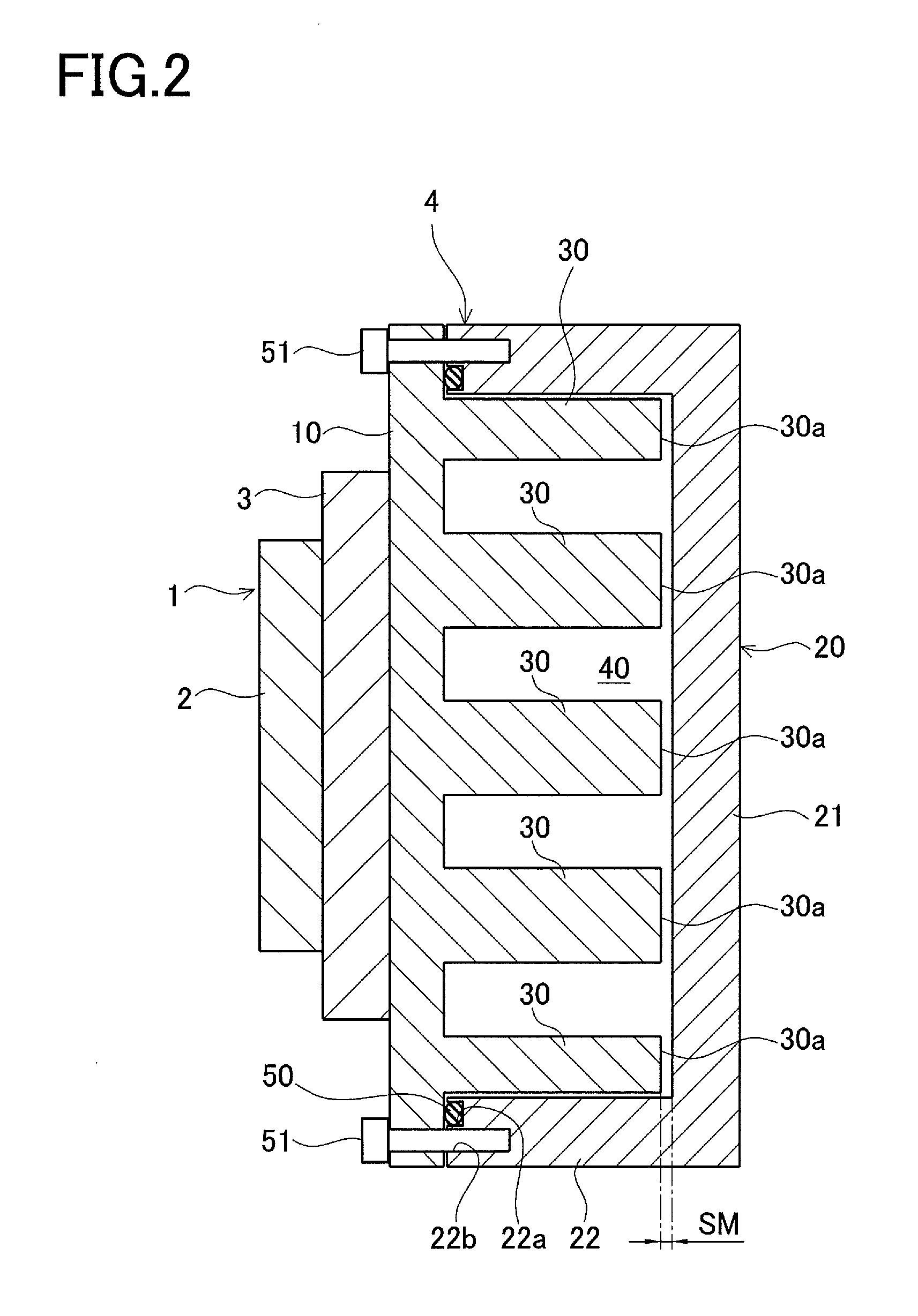

first embodiment

[0069]The advantageous effects of the cooler 4 of the first embodiment will be described. In this cooler 4, as shown in FIG. 9, the banks 31x create flows of the coolant 40 from the raised curved portions 31 toward the opposite lowered curved portions 32. Thereby, the part MS1 of the main stream MS of the coolant 40 can be mixed with the coolant 40 stagnating near the lowered curved portions 32, whereby the heat transfer coefficient of the wavy fins 30 can be improved. Thus, stagnation of the coolant 40 near the lowered curved portions 32 can be prevented, so that the cooler 4 can have enhanced cooling performance.

[0070]In the cooler 4 of the first embodiment, as shown in FIG. 7, the banks 31x provided at the base portions 31a create flows of coolant from the base portions 31a of the raised curved portions 31 toward the opposite lowered curved portions 32. Thereby, the coolant 40 is disturbed near the base portions 31a of the wavy fins 30 where the temperature is relatively high. Th...

second embodiment

[0094]In the second embodiment, one protrusion 31y is provided on each raised curved portion 31. Alternately, a plurality of protrusions 31y may be provided on each raised curved portion 31. For example, two protrusions 31y may be provided at the base portion 31a of the raised curved portion 31. Alternatively, one protrusion 31y may be provided at the base portion 31a of the raised curved portion 31, and another protrusion 31y may be provided at the distal portion 31b of the raised curved portion 31. The shape and the size of the protrusions 31y can be changed as required.

third embodiment

[0095]In the third embodiment, the banks 31x are provided at the base portions 31a of the raised curved portions 31, while the second banks 21x are provided at the distal portions 31b of the raised curved portions 31. Alternately, protrusions may be provided at the base portions 31a of the raised curved portions 31 instead of the banks 31x. Alternatively, protrusions may be provided at the distal portions 31b of the raised curved portions 31 instead of the second banks 21x.

[0096]In the forth embodiment, the second banks 90x are provided on the sheet member 90. Alternately, protrusions may be provided on the sheet member 90.

[0097]In each embodiment mentioned above, the distance (flow path width) of the adjacent wavy fins 30 is made constant at any points in the flowing direction, but it may be changed at any points in the flowing direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com