Method of automatically twisting silk threads of raw silks of automatic silk reeling machine

A silk reeling machine and silk sliver technology, which is applied in the field of automatic silk reeling machine twisting, can solve the problems of large space occupation, poor quality of silk sliver, and complicated process of changing yarn bobbins, so as to save production costs, improve raw silk quality, Achieve full utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with the embodiment of the invention the present invention is described in further detail:

[0036] A method for automatically twisting raw silk sliver of an automatic silk reeling machine, said method comprising the following steps:

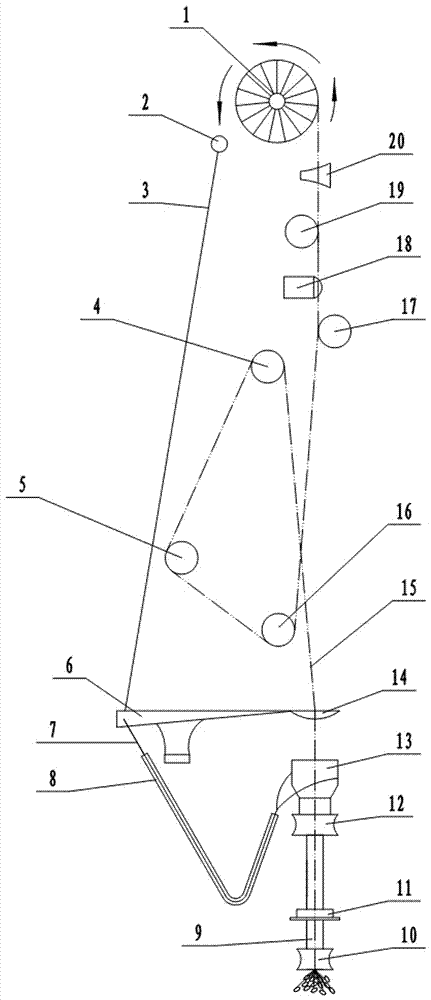

[0037] (1) Lengthen the length of the wire pipe on the existing Bailing platform, and install a friction wheel above the wire pipe, install a twister above the friction wheel, and the friction wheel is coupled with the twister, driven by the friction wheel The twister rotates clockwise at a high speed of 1400 rpm, and completes the automatic twisting process of the filament during the production process;

[0038] (2) Change the single transmission wheel on the existing thread-collecting wing transmission box into an upper and a lower double-drive wheel, respectively drive the thread collection device and the friction wheel with the rotary rope, and the friction wheel drives the twister;

[0039] (3) Increase the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com