Energy-saving and environmentally-friendly automatic tussah silk reeling machine

An energy-saving, environmentally friendly, silk reeling technology, applied in the direction of silk reeling, sustainable manufacturing/processing, climate sustainability, etc., to achieve the effect of increasing the reeling recovery rate, improving labor productivity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

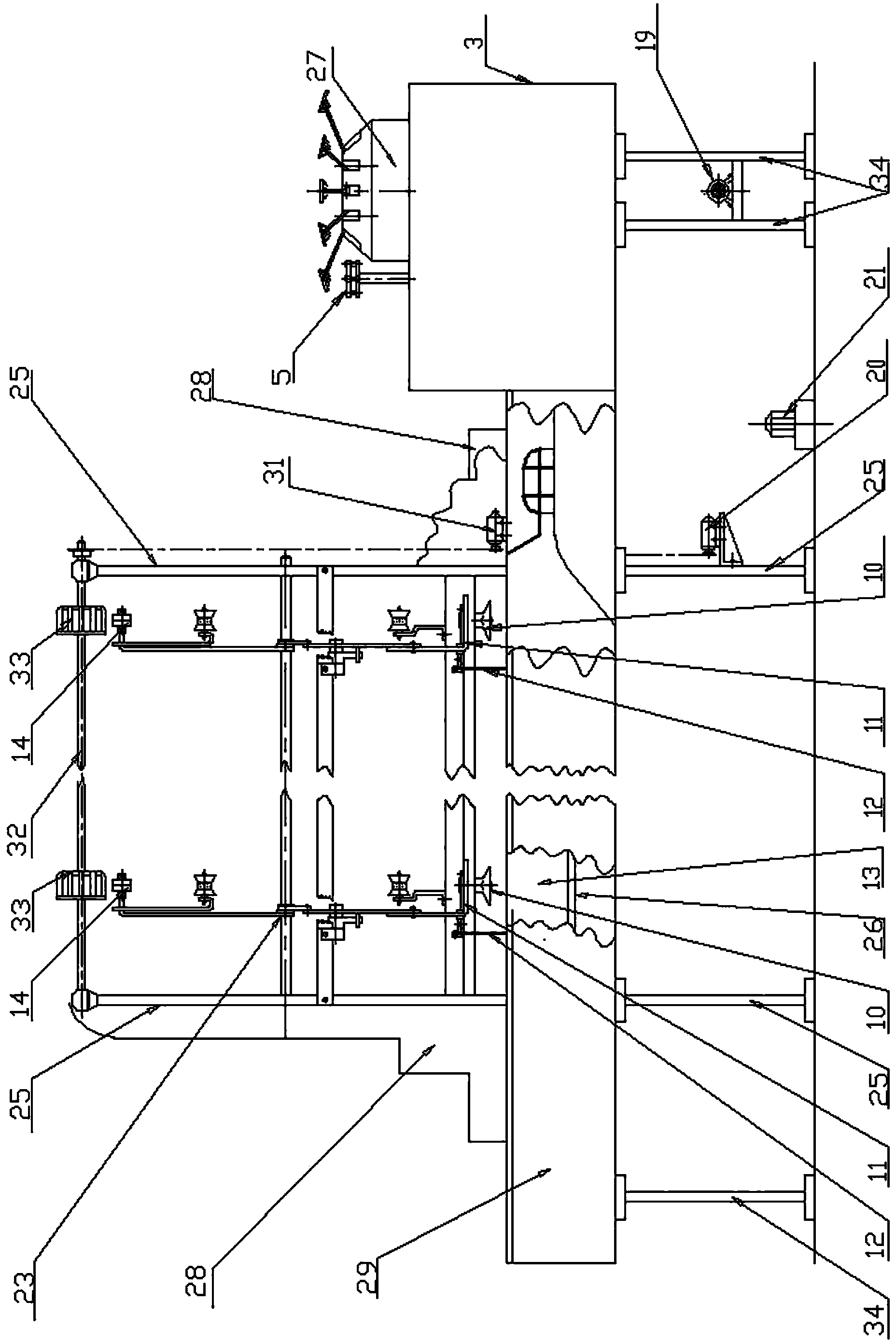

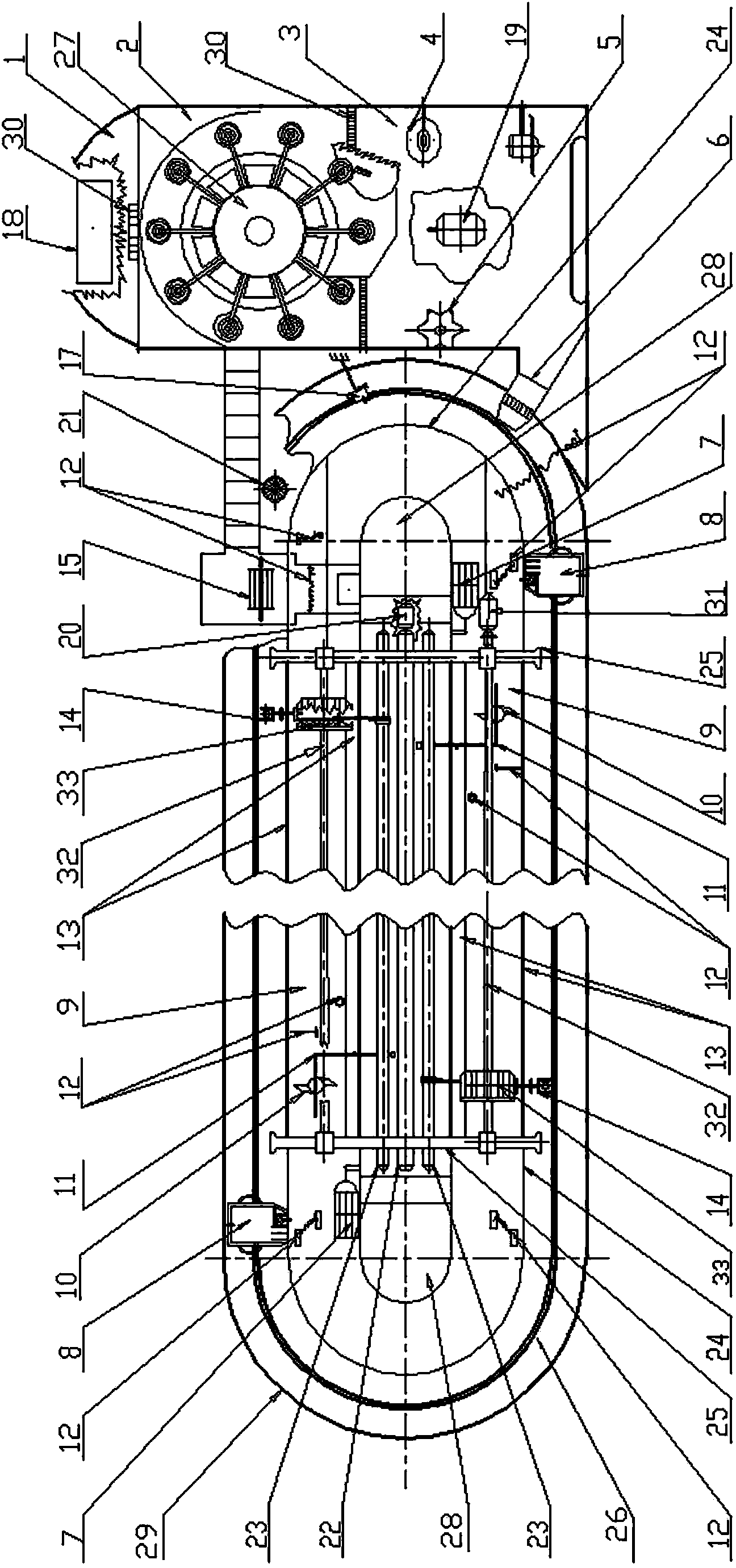

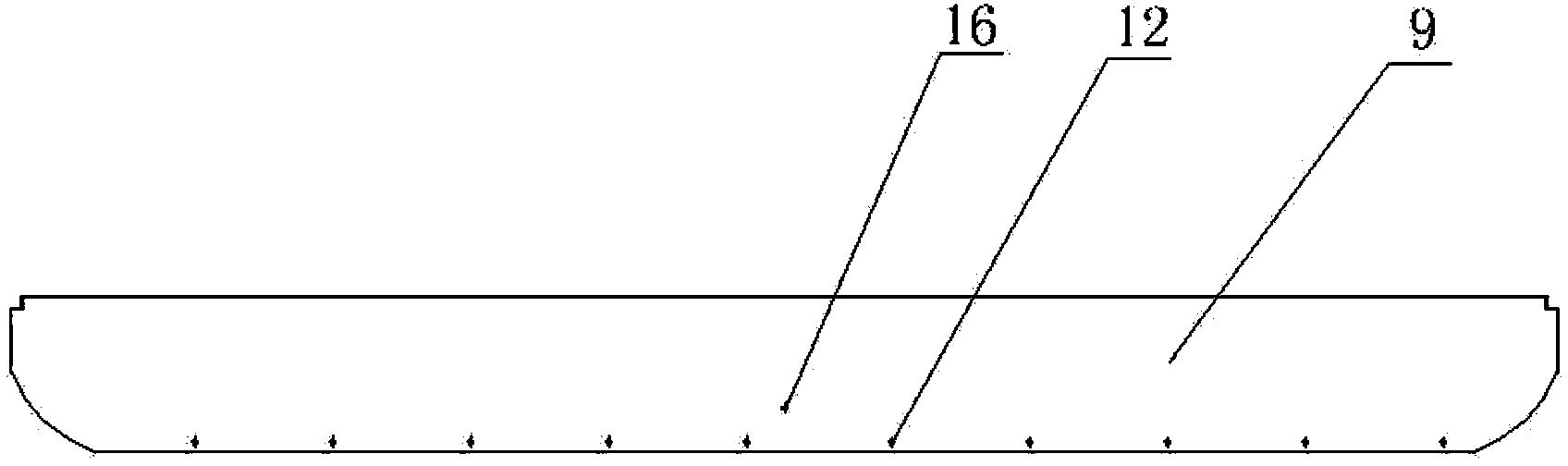

[0011] This machine is suitable for automatic reeling of all tussah cocoons. What present embodiment provides is the automatic silk reeling machine of a kind of 20 threads scale of energy-saving and environment-friendly type tussah silk that produces 100D tussah silk, as figure 1 , Figure 2, image 3 with Figure 4 As shown, the cocoon preparation pot 1 is set above the automatic threading pot 2, the automatic threading pot 3 is set under the automatic threading pot 2, between the cocoon preparation pot 1 and the automatic threading pot 2, the automatic threading pot 2 and the automatic threading pot 3 are respectively provided with a cocoon-adding lifting bucket 30, and the automatic threading pot 2 is provided with several threading brushes 27, the eccentric disc 4 is arranged in the automatic threading pot 3, and the winding device 5 is arranged on the On the upper left side of the automatic silk reeling pot 3, the automatic cocoon adding mouth 6 is arranged on the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com