Device and method for replacing croisures

A silk sheath and silk strip technology, applied in the direction of silk reeling, can solve the problems of non-uniform silk sheath quality, affecting the quality of raw silk, low labor productivity, etc., so as to reduce non-uniformity, improve scientificity and rationality, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

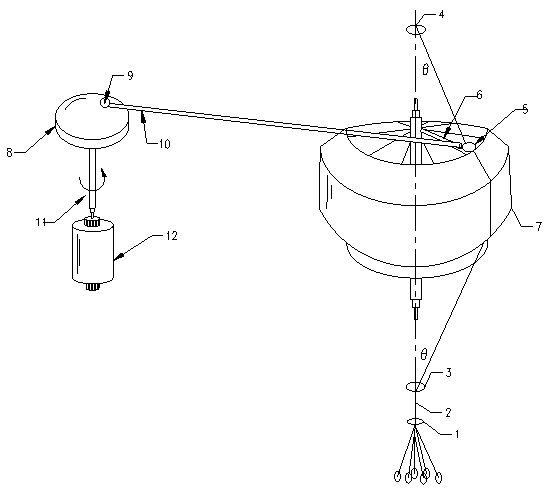

[0030] 20 / 22D autumn cocoon raw silk is reeled, the reeling speed is 80 m / min, and the average number of cocoon grains is 7.8. The thread after passing through the thread collector 1, after passing through the lower guide hook 3, passes through the thread guide ring 5 on the top of the rocker, relying on the angle θ (30°) between the thread and the axis to make the thread close to the height 10cm, diameter is 8 centimetres, and outer wall surface material is the class twist disc 7 of polyurethane rubber, does 45 ° of fan motion, and the speed of fan motion is 120 times / min, and the silk strip after doing fan motion enters upper guide wire hook 4, Complete the effect similar to silk sheath. reeling small For silk flakes, the moisture regain of doffing is 14.2%, the cohesion of the reeled raw silk is 106 times, the cleanness is 94 points, and the cleanness is 98.5 points.

Embodiment 2

[0032] 27 / 29D spring cocoon raw silk is reeled, the reeling speed is 75 m / min, and the average number of cocoon grains is 9.6. The thread after passing through the thread collector 1, after passing through the lower guide hook 3, passes through the thread guide ring 5 on the top of the rocker, relying on the angle θ (15°) between the thread and the axis to make the thread close Paste height 5cm, diameter is 5 centimeters outer wall surface material is the quasi-twist plate 7 of silicon rubber, does 90 ° of fan motion, and the speed of fan motion is 90 times / min, and the silk strip after doing fan motion enters upper guide wire hook 4 , to complete the work similar to the silk sheath. reeling small For silk flakes, the moisture regain of doffing is 16.5%, the cohesion of raw silk is 110 times, the cleanness is 93.5 points, and the cleanness is 98 points.

Embodiment 3

[0034] 40 / 44D spring cocoon raw silk is reeled, the reeling speed is 70 m / min, and the average number of cocoon grains is 14.2. The thread after passing through the thread collector 1, after passing through the lower guide hook 3, passes through the thread guide ring 5 on the top of the rocker, relying on the angle θ (35°) between the thread and the axis to make the thread close to the height 10cm, diameter is 8 centimetres, and outer wall surface material is the quasi-twist plate 7 of silicon dioxide / polyurethane composite material, does 120 ° fan motion, and the speed of fan motion is 30 times / min, and the silk strip after doing fan motion enters upper Guide wire hook 4, finishes twisting sheath work. reeling small For silk flakes, the moisture regain of doffing is 16.5%, the cohesion of raw silk is 105 times, the cleanness is 94 points, and the cleanness is 97 points.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com