Improved reeling machine

A technology of silk reeling machine and frame, which is applied in the direction of silk reeling, which can solve the problems of many broken ends and low grade of raw silk, and achieve the effects of uniform feeding, improved quality and avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

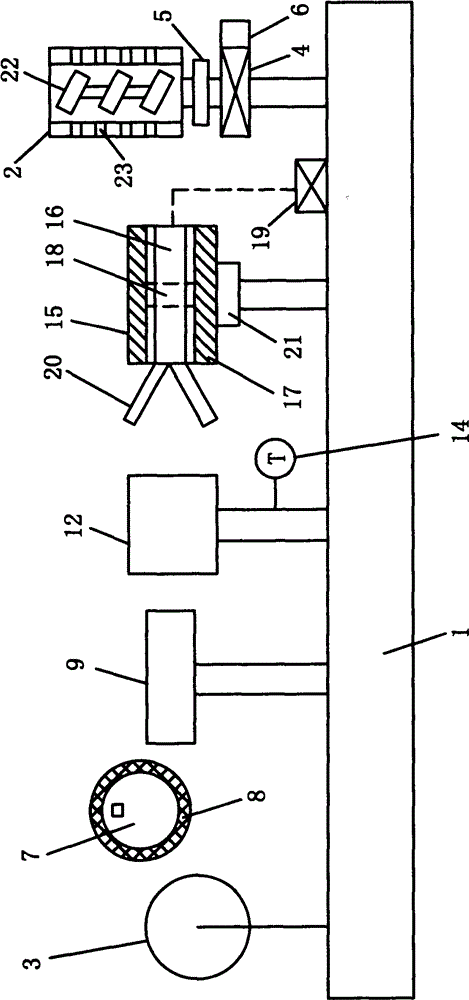

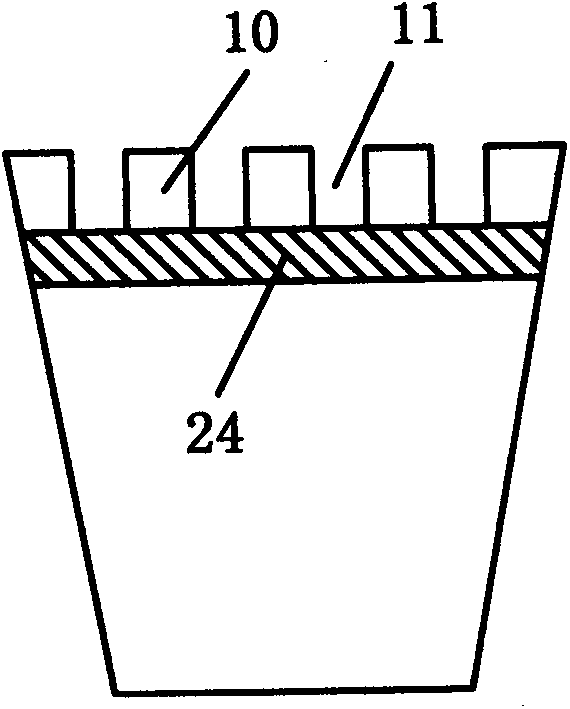

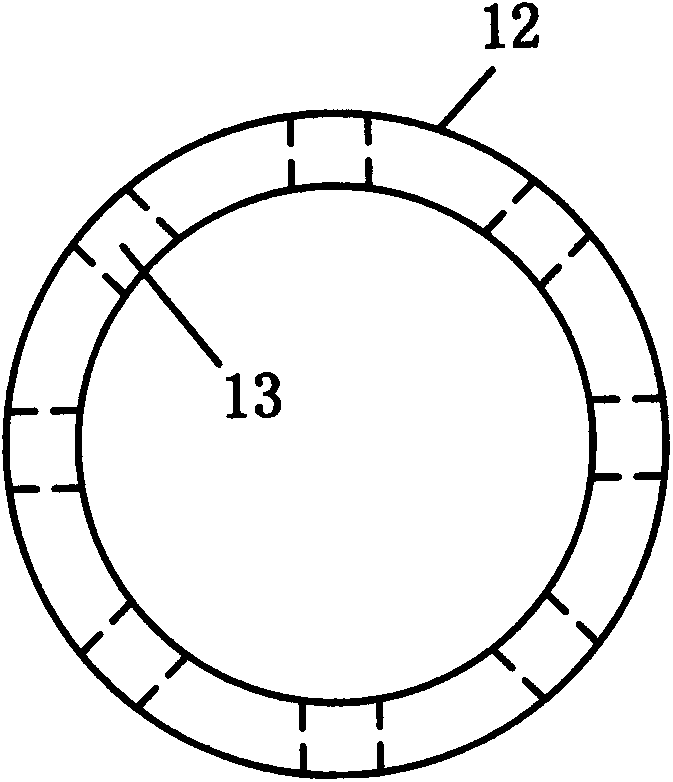

[0037] Reference Figure 1-3 , A specific embodiment of the present invention includes a frame 1, the frame 1 is provided with a take-up wheel 2 and a wire feed wheel 3, the take-up wheel 2 is provided with a drive motor 4, and the drive shaft of the drive motor 4 is provided with an encoder 5 , The drive motor 4 is connected to the frequency converter 6, the eccentric wheel 7 is arranged between the wire take-up wheel 2 and the wire feed wheel 3, the surface of the eccentric wheel 7 is provided with a rough layer 8, and the eccentric wheel 7 and the wire take-up wheel 2 are arranged rationally A number of claw heads 10 are provided on the top of the thread claw 9, a gap 11 is provided between two adjacent claw heads 10, and an annular steam spray head 12 is provided between the thread claw 9 and the take-up wheel 2. A number of air jets 13 are evenly arranged on the inside of the steam nozzle 12, a temperature sensor 14 is arranged on the air inlet pipe of the annular steam no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com