Expansion water flow arranging device for automatic silk reeling machine

A technology of silk reeling machine and water flow is applied in the field of automatic silk reeling machine separating thread arrangement device, which can solve the problems of affecting the thread arrangement effect and the like, and achieve the effect of simple structure and prevention of reeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

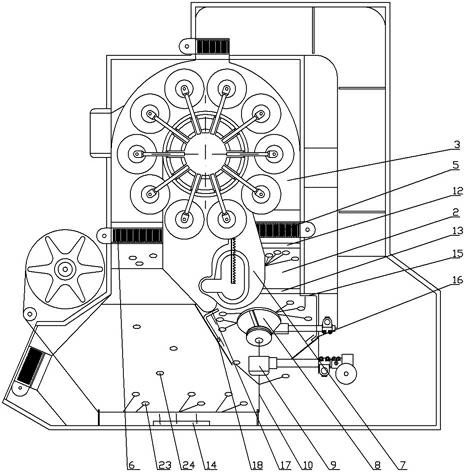

[0022] Embodiment 1: a kind of automatic silk reeling machine tension water flow arrangement device of this example, as figure 1 , figure 2 , including the Rixu pot 2 and the Suoxu pot 3, the Rixu pot and the Suoxu pot are integrated, and the Lixu pot and the Suoxu pot are connected to each other, and the Suoxu pot is respectively equipped with a thread and a cocoon bucket 5, without thread adding cocoon hopper 6, the third water adding pipe 14 that can spray water to the threadless adding cocoon hopper is provided on the pot wall of the rice cooker. The rack at the entrance of the rice cooker is provided with an eccentric plate 8 and a needle 9 in turn. The eccentric plate is connected with a braid 10 that can pull threaded cocoons. The water head 11 is provided with the first water adding pipe 12 that can spray water in the threading pot. A second water supply pipe 13 is provided in the water tank of the water spray head and the first water supply pipe, a first water flow...

Embodiment 2

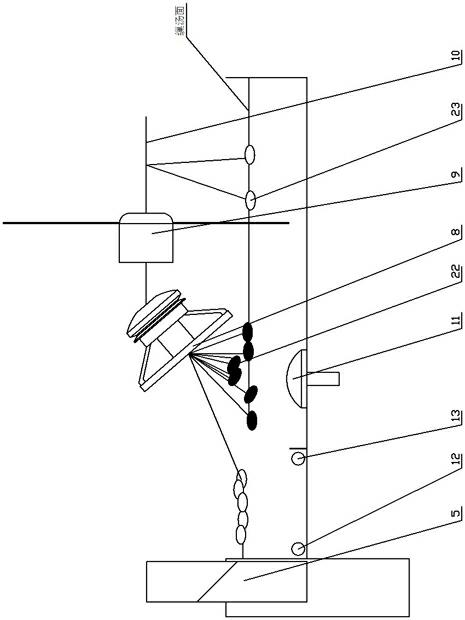

[0024] Embodiment 2: a kind of automatic silk reeling machine tension water flow arrangement device of this example, as image 3 , Figure 4 , including the Rixu pot 2 and the Suoxu pot 3, the Rixu pot and the Suoxu pot are integrated, and the Lixu pot and the Suoxu pot are connected to each other, and the Suoxu pot is respectively equipped with a thread and a cocoon bucket 5. No thread plus cocoon bucket 6. The rack at the entrance of the rice cooker is provided with an eccentric plate 8 and a needle 9 in turn. The eccentric plate is connected with a braid 10 that can pull threaded cocoons. The water head 11 is provided with the first water adding pipe 12 that can spray water in the threading pot. The second water supply pipe 13 is provided in the water tank of the water spray head and the first water supply pipe, and the bottom of the rice cooker below the eccentric plate is an inclined plane 19. The outlet of the Suoxu pot is provided with a sawtooth roughening device 23...

Embodiment 3

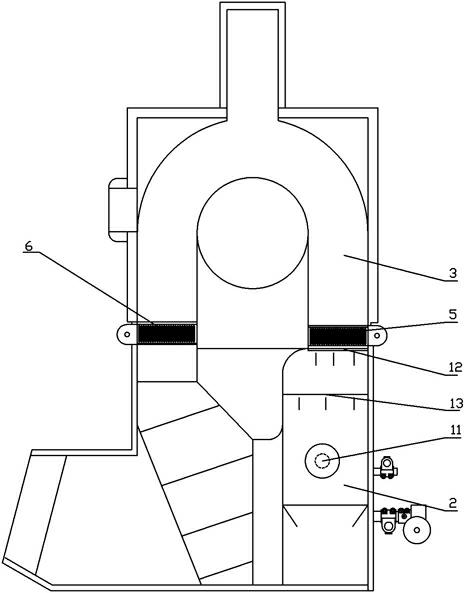

[0026] Embodiment 3: a kind of automatic silk reeling machine tension water flow arrangement device of this example, as Figure 5 , Image 6 , Figure 7, including the Rixu pot 2 and the Suoxu pot 3, the Rixu pot and the Suoxu pot are integrated, and the Lixu pot and the Suoxu pot are connected to each other, and the Suoxu pot is respectively equipped with a thread and a cocoon bucket 5. No thread plus cocoon bucket 6. The rack at the entrance of the rice cooker is provided with an eccentric plate 8 and a needle 9 in turn. The eccentric plate is connected with a braid 10 that can pull threaded cocoons. The water head 11 is provided with the first water adding pipe 12 that can spray water in the threading pot. This is provided with a small groove 1 between the water spray head and the first water adding pipe. One end of the water spray head is connected with a water return tank 20, and the two sides of the water spray head are respectively provided with a water flow box 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com