Water flow neatening device for automatic silk reeling machine

A silk reeling machine and automatic technology, which is applied in the field of automatic silk reeling machine water flow finishing device, can solve the problems that affect the effect of threading, rough cocoons are not easy to break up, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

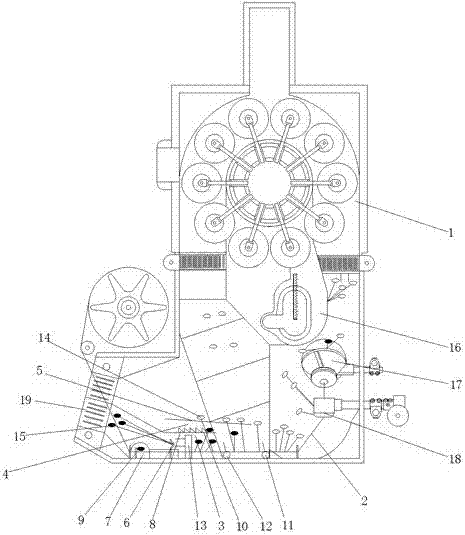

[0013] Embodiment: a kind of automatic silk reeling machine water flow finishing device of this example, as figure 1 , including a straightening pot 1, a silk braid 2 is provided in the space between the needle in the straightening pot and the automatic cocoon adding bucket, and a first flushing pipe 11 and a second flushing pipe 12 are arranged on the path that the silk braid passes. The passing path is divided into a first passage 3 through which fluffy cocoons can pass through and a second passage 4 through which Zhengxu cocoons can pass through by a partition 10. The second passage is provided with a baffle plate 5 outside, and the first flushing pipe is located at At the inlet end of the baffle, the second flushing pipe is arranged at the inlet end of the second channel, and the first channel is provided with a third flushing pipe 12 capable of spraying water to the water surface. The outlet of the first channel is provided with a guide wire hook 6 and a cocoon bucket 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com