Automatic temperature control apparatus and method in reeling silk production process

An automatic control device and production process technology, applied in the direction of temperature control, non-electric variable control, electric fluid pressure control, etc., can solve the problems of high labor intensity, large temperature value lag, and large sericin dissolution loss. Achieve the effect of improving silk reeling production efficiency, improving the ability of disturbance, and easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

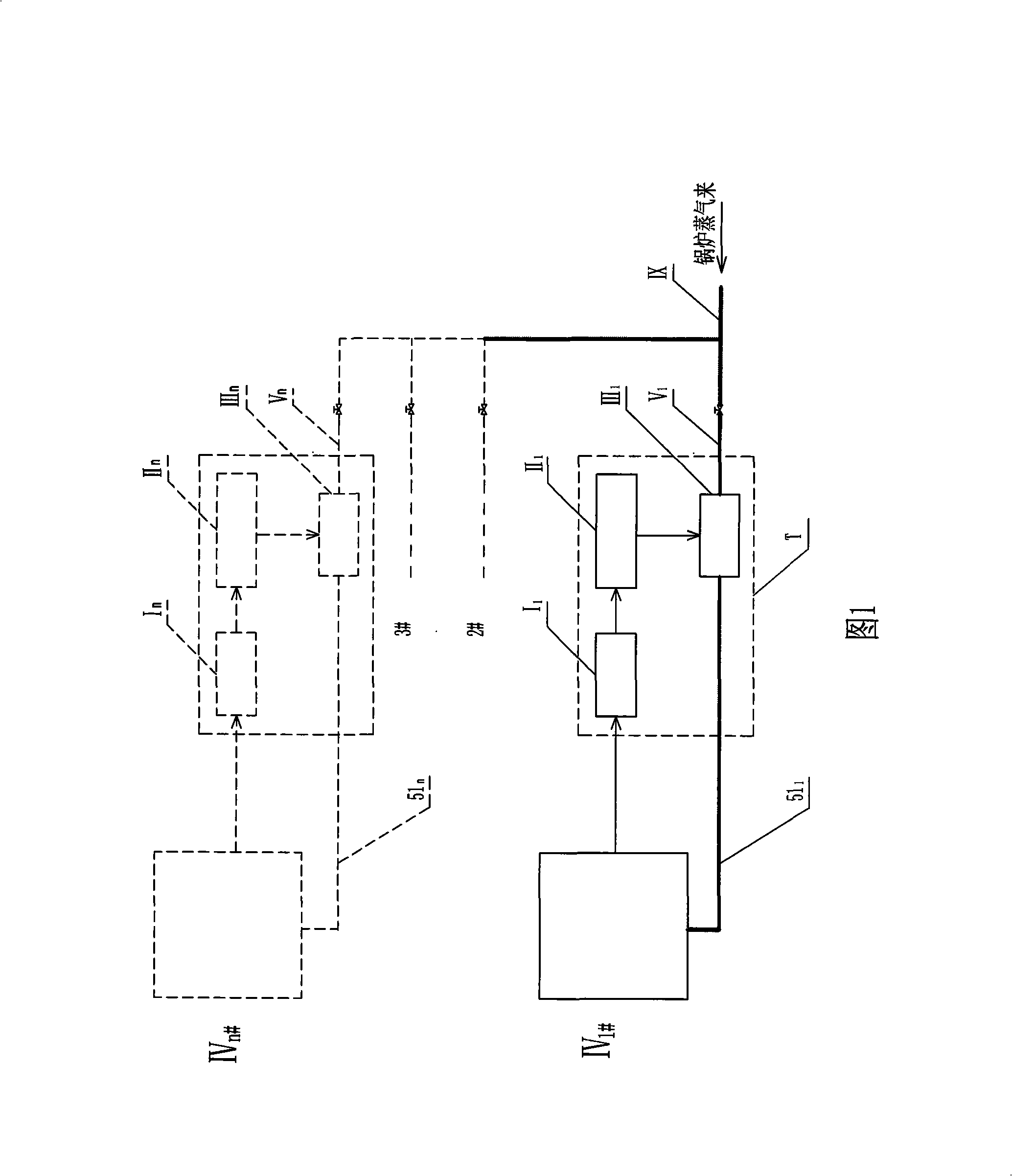

[0052] A kind of process temperature automatic control device used in the silk reeling production process (full name: a kind of temperature automatic control device used in the process temperature control point in the silk reeling production process), as shown in Figure 1, the process temperature automatic control device Including n process temperature regulation loops, the value range of n is: 1≤n≤32;

[0053] Each process temperature regulation loop includes temperature measurement part I, temperature display control part II and automatic regulating valve part III;

[0054] The temperature measurement part includes a temperature measurement sensor and a temperature measurement sensor installation connector; the temperature measurement sensor is installed in the process device IV designed with a process temperature control point, and converts the temperature of the measured medium—water or steam in real time It is in the form of an electrical signal and transmitted to the tem...

Embodiment 2

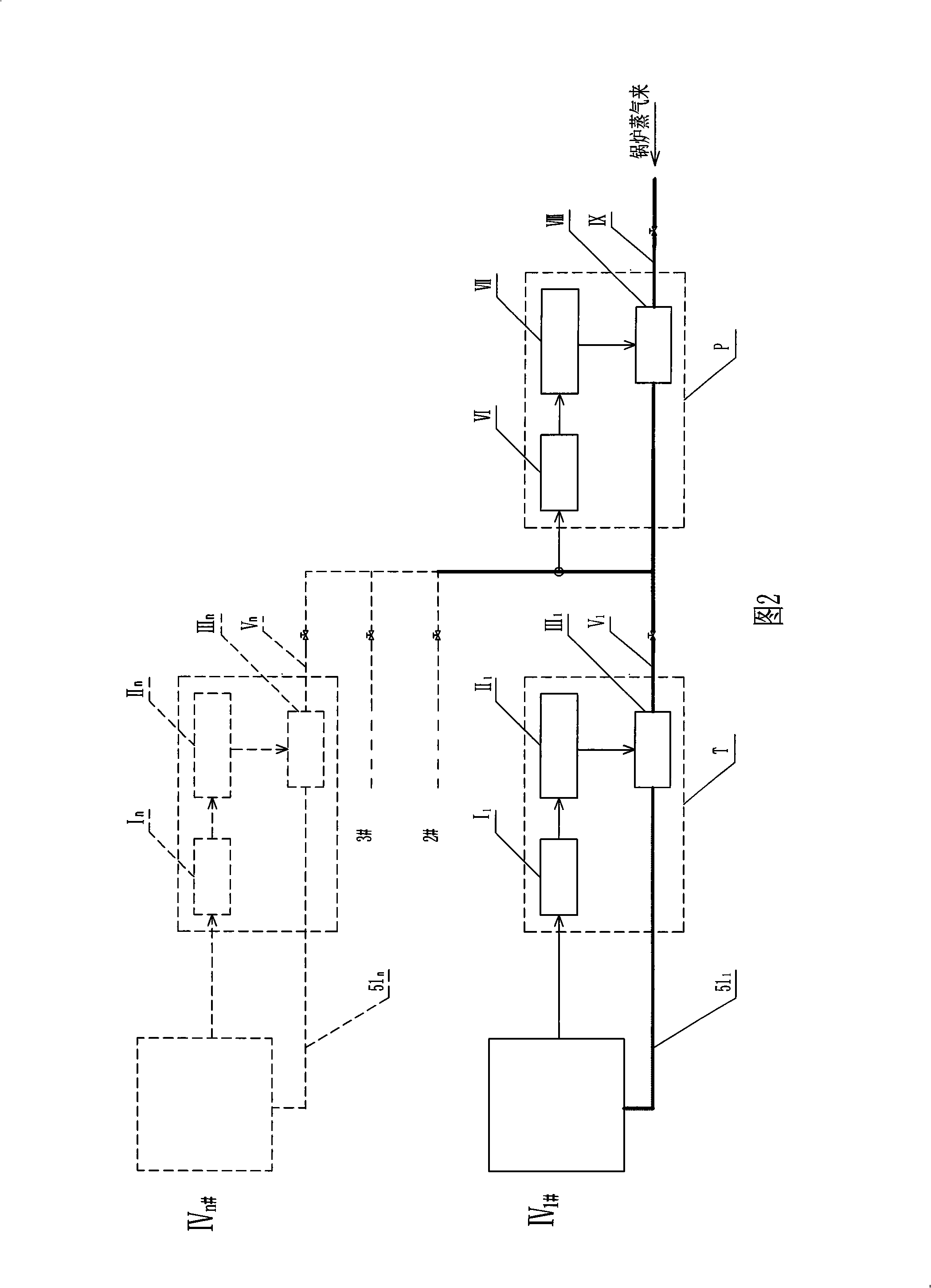

[0058] The utility model relates to an automatic temperature control device used in the silk reeling production process with a steam pressure regulating circuit.

[0059] As shown in Figure 2, the device has n parts consisting of a temperature measurement part I, a temperature display control part II and an automatic regulating valve part III (the value range of n is: 1≤n≤32) In addition to the process temperature regulating circuit T, it also includes a steam pressure regulating circuit P composed of a pressure measurement part, a pressure display control part and an automatic regulating valve part, and the steam pressure regulating circuit P is installed before each temperature regulating circuit;

[0060] The pressure measurement part includes a root cut-off valve, a pressure guide pipe, and a pressure sensor; the pressure sensor converts the pressure in the steam main pipe of the process device before entering the process device into an electrical signal through the root st...

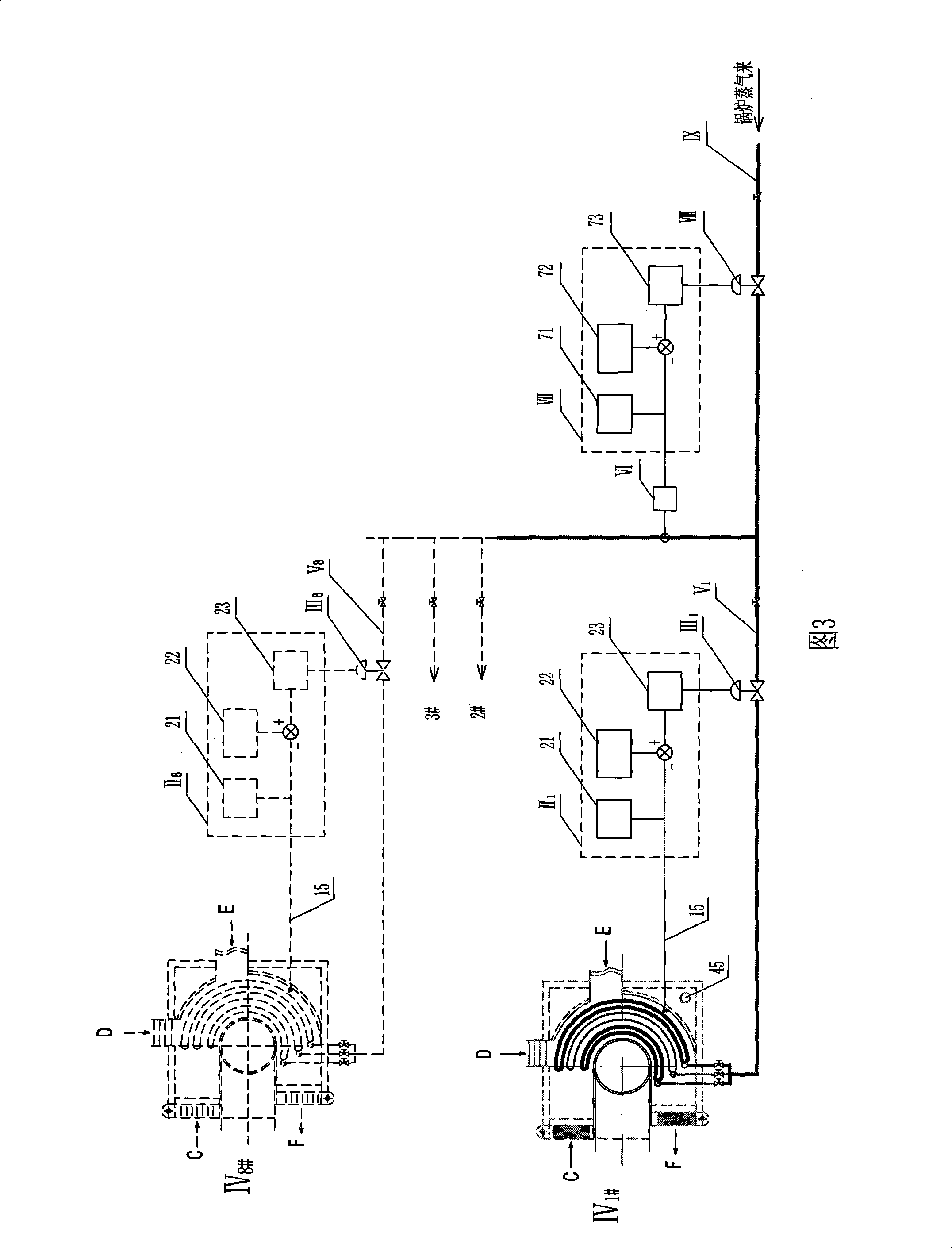

Embodiment 3

[0064] The invention relates to an automatic temperature control method for process temperature control points in the silk reeling production process. (hereinafter referred to as: a kind of temperature automatic control method used in the silk reeling production process), it adopts the temperature control method in the silk reeling production process which is composed of the steam pressure regulating circuit and the temperature regulating circuit described in the second embodiment of the present invention. The automatic control device is a hierarchical adjustment method in which the pressure in the steam inlet main pipe of the workshop is first adjusted by the steam pressure adjustment circuit, and then the temperature of the temperature control point of the process is automatically adjusted by the temperature adjustment circuit;

[0065] The method of regulating the pressure in the steam inlet main pipe of the workshop by the steam pressure regulating circuit is: connect the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com