Microwave oven with rolled bin

A technology for microwave ovens and warehouses, applied in the field of microwave ovens, can solve the problems of uneven baking and troublesome production process, and achieve the effects of good taste, uniform degree and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

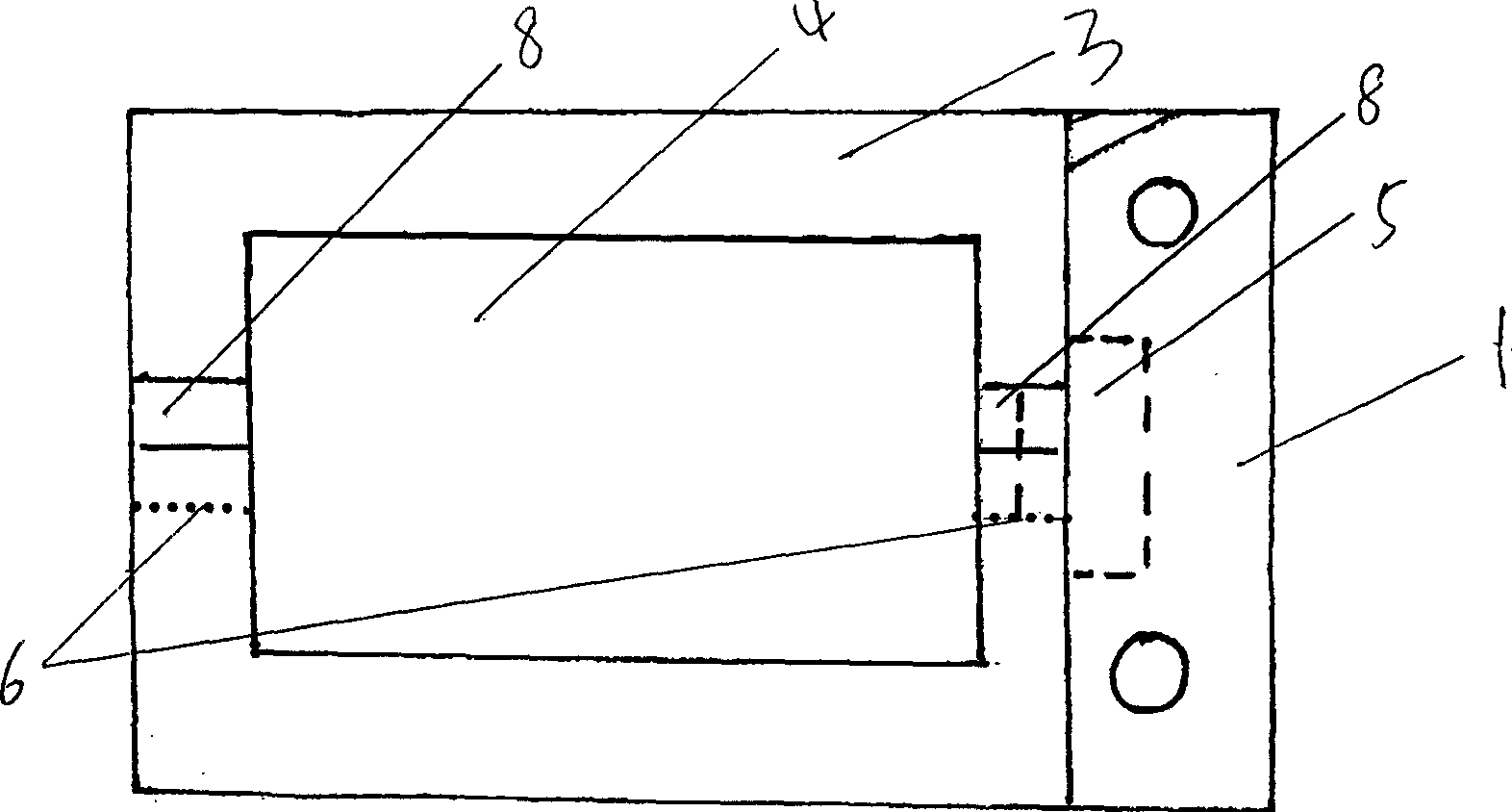

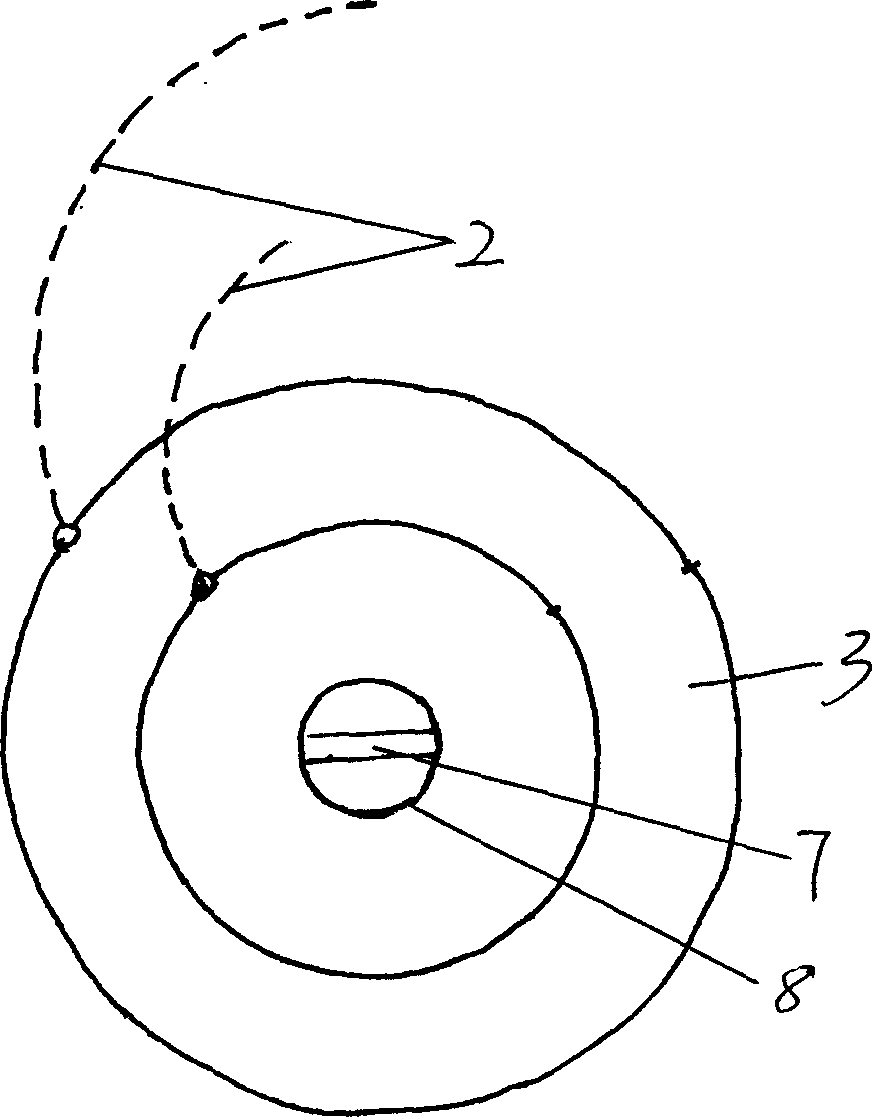

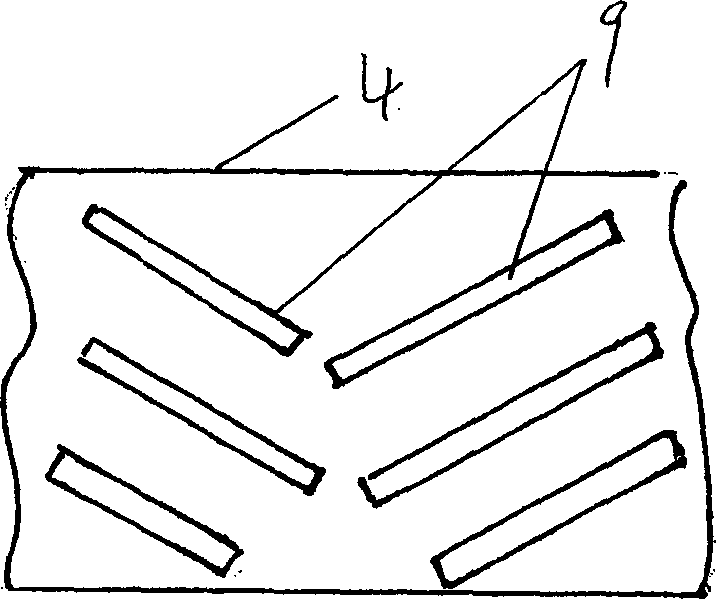

[0017] Example 1. figure 1 It is a schematic structural view of a drum-type microwave oven with a warehouse 4. In order to effectively use the space, the body of oven 1 of the microwave oven is also made into a cylinder (such as figure 2 ). The drive shaft 5 of this microwave oven is arranged on the side wall of the furnace 3 close to the control panel, driven by a reduction motor, and the motor is linked with the furnace door 2, and the motor cannot run when the furnace door 2 is opened. The microwave tube of the microwave oven is arranged above the wall of the front furnace 3 according to the axial direction of the drum warehouse 4, so as to facilitate the food to be evenly irradiated by microwaves. The warehouse 4 is made of a microwave-resistant and heat-resistant material in the shape of a drum, and there are air holes on it, which can make the warehouse 4 a sieve shape, so as to facilitate the discharge of the gas generated during the microwave; The head 8 is a short ...

Embodiment 2

[0018] Example 2. Figure 6 It is a structural schematic diagram of a microwave oven with a spindle-shaped warehouse 4. This microwave oven is suitable for roasting a large number of dried fruits, so the furnace 3 and cargo warehouse 4 of this microwave oven are also relatively large. The furnace body 1 of this microwave oven is square, and for making furnace door 2 have bigger opening, furnace door 2 comprises furnace body 1 top and front part, and door axle is located at furnace body 1 top, and furnace door 2 is gull wing shape when opening. The warehouse 4 is in the shape of a spindle, and the two ends of the spindle are respectively equipped with a shaft groove matched with the drive shaft 5 and the door of the warehouse 4. The warehouse 4 is placed in the furnace 3 at an angle of 45 degrees with the axis of symmetry and the horizontal plane. The door is facing upwards, which is convenient for observation and feeding and discharging; the door of the warehouse is round, and...

Embodiment 3

[0019] Embodiment 3. In the situation of embodiment 1, the warehouse 4 is connected with a pair of roller discs 10 with the central axis instead (as Figure 4 , 5 ), uniform corresponding holes 11 are established on the two roller discs 10, string food can be placed; if electric heating tubes are established in the central axis, power electrodes are established in the two shaft grooves, then the microwave oven can be made to have a barbecue function. The electrode of the electric heating tube is arranged in the shaft head 8, and the electrode in the shaft groove is in contact with the electrode of the electric heating tube through a reed or a brush, so as not to affect the putting in and taking out of the cargo compartment 4; 2 linked, when the furnace door 2 is opened, the power electrode is disconnected. The above design enables the microwave oven not only to grill skewered dried fruit but also to grill skewered meat, and to make the food charred on the outside and tender o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com