Organic fertilizer for fire-cured tobacco and production method thereof

A production method and technology of organic fertilizer, applied in the direction of organic fertilizer and the like, can solve the problems such as effect discount and limited nutrients, and achieve the effects of increasing aroma, increasing oil content and increasing proportion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

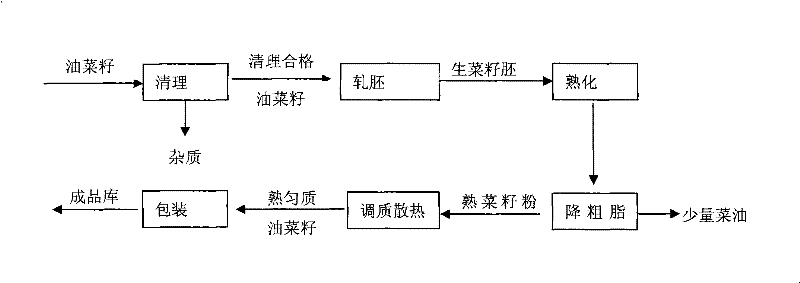

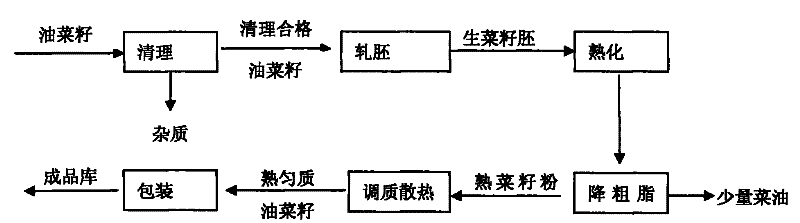

[0029] The production method of flue-cured tobacco organic fertilizer comprises the following steps:

[0030] (1) Clean up:

[0031] The rapeseed is controlled within 10% of water, 30% of oil, and within 2% of impurities. The total impurity can reach 45%, without mildew and deterioration; after cleaning the rapeseed, ensure that the impurity is within 0.5%, and the cleaned out impurities ( Large miscellaneous and small miscellaneous) contain no more than 1% of rapeseed;

[0032] (2) Embossing:

[0033] Adjust the water content of the qualified rapeseed to 5% before rolling, the thickness of the rapeseed embryo is 0.5mm, the embryo sheet is even and firm, less powdery, and no oil;

[0034] (3) ripening:

[0035] After the rapeseed has been flaked, the water content of the raw embryo is adjusted to 20%, and then steamed to 60°C by superheated steam, using direct steam and indirect steam, and the water content is controlled at 5% for 80 minutes;

[0036] (4) Crude fat reducti...

Embodiment 2

[0043] The production method of flue-cured tobacco organic fertilizer comprises the following steps:

[0044] (1) Clean up:

[0045] The rapeseed is controlled within 10% of water, 38% of oil, and within 2% of impurities. The total impurity can reach 5%, without mildew and deterioration; after cleaning the rapeseed, ensure that the impurity is within 0.5%, and the cleaned out impurities ( Large miscellaneous and small miscellaneous) contain no more than 1% of rapeseed;

[0046] (2) Embossing:

[0047] Adjust the water content of the qualified rapeseed to 10% before rolling, the thickness of the rapeseed embryo is 0.35mm, the embryo is uniform and firm, less powdery, and no oil is exposed;

[0048] (3) ripening:

[0049] After the rapeseed has been flaked, the water content of the raw embryo is adjusted to 23%, and then steamed to 80°C by superheated steam, using direct steam and indirect steam, and the water content is controlled at 8%, and the time is 100 minutes;

[0050...

Embodiment 3

[0057] The production method of flue-cured tobacco organic fertilizer comprises the following steps:

[0058] (1) Clean up:

[0059] The rapeseed is controlled within 10% of water, 35% of oil, and within 2% of impurities, and the total impurity can reach 4-5%, without mildew and deterioration; after the rapeseed is cleaned, the impurities are guaranteed to be within 0.5%. Impurities (big and small) contain no more than 1% of rapeseed;

[0060] (2) Embossing:

[0061] Adjust the water content of the qualified rapeseed to 8% before rolling, the thickness of the rapeseed embryo is 0.4mm, the embryo sheet is even and firm, less powdery, and no oil;

[0062] (3) ripening:

[0063] After the rapeseed has been flaked, the water content of the raw embryo is adjusted to 25%, and then steamed to 90°C by superheated steam, using direct steam and indirect steam, and the water content is controlled at 10%, and the time is 120 minutes;

[0064] (4) Crude fat reduction:

[0065] At a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com