Nut leisure food processing equipment

A processing equipment and snack food technology, which is applied in food processing, food science, filtering and screening, etc., can solve the problems of different sizes of nuts and affect the quality, and achieve the effect of uniform nut size, high processing efficiency and convenient sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

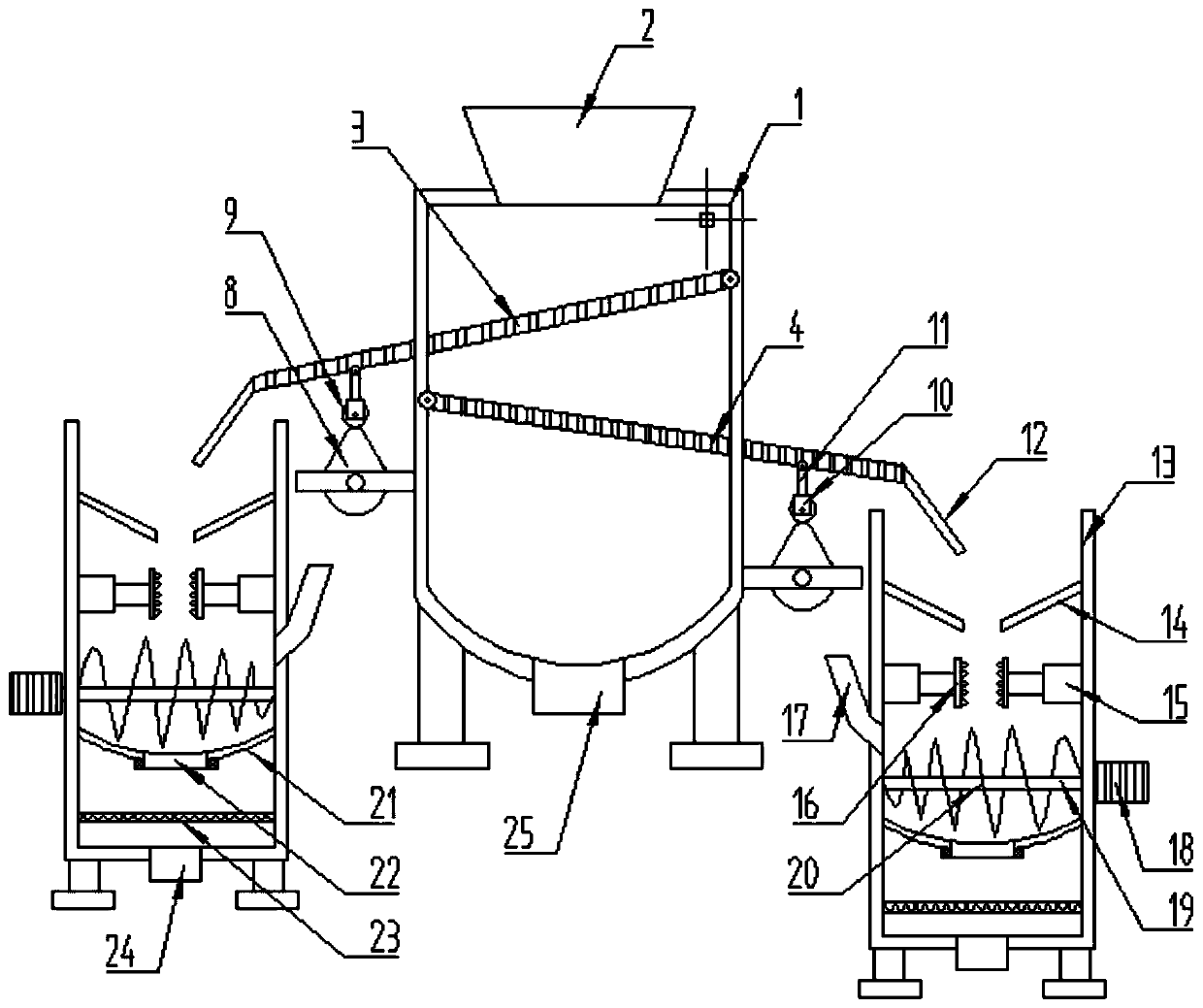

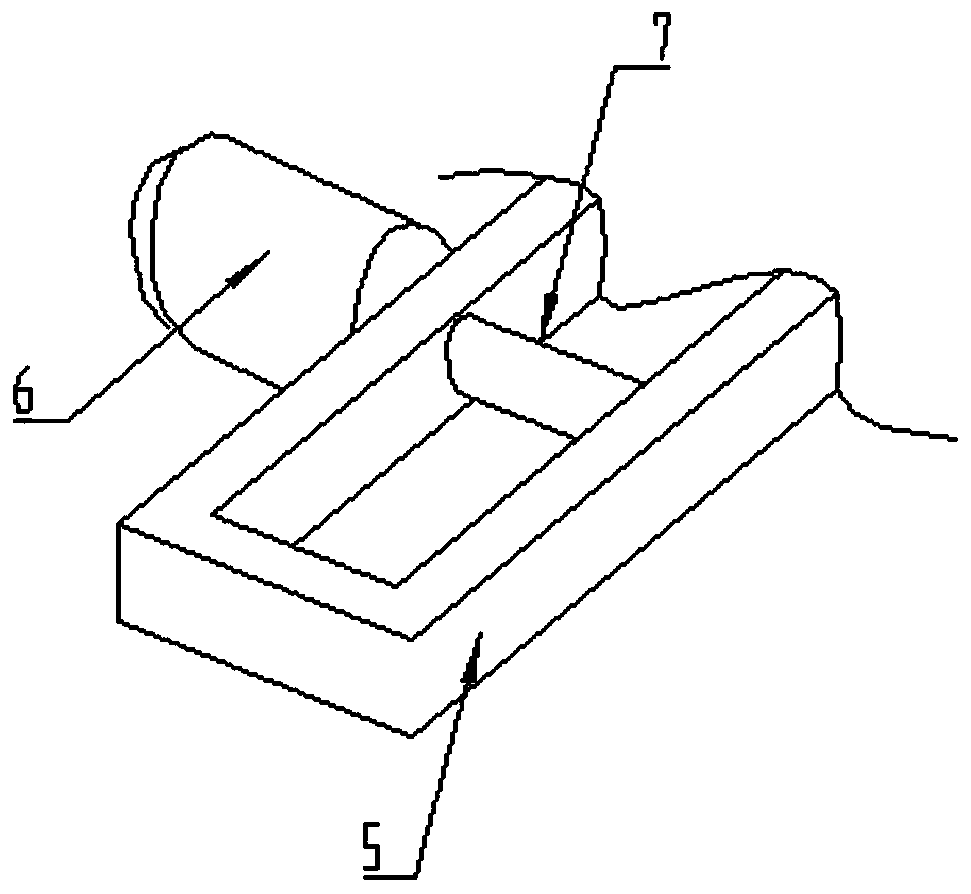

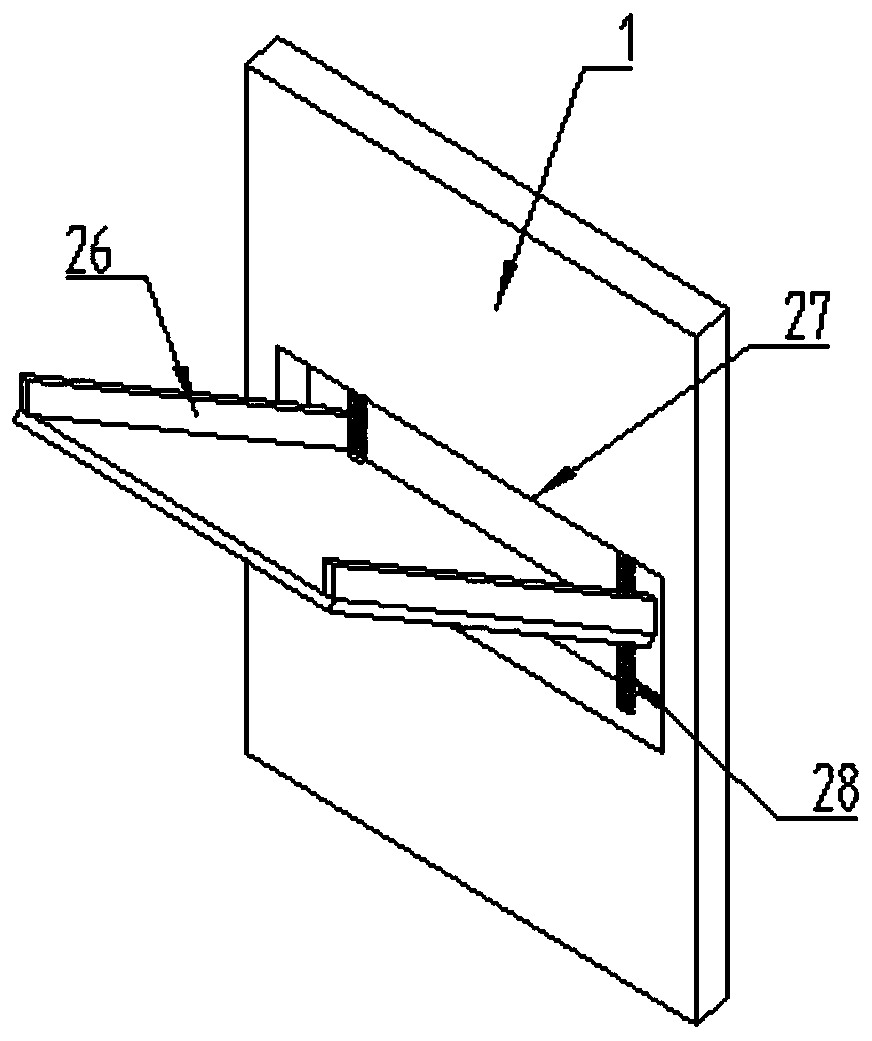

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a kind of nuts snack food processing equipment, and described processing equipment comprises screening box 1, and the top of described screening box 1 is provided with feeding hopper 2, and the bottom of described screening box 1 is provided with The second slag outlet 25, the inside of the screening box 1 is sequentially provided with a primary sieve plate 3 and a secondary sieve plate 4; the primary sieve plate 3 and the secondary sieve plate 4 are movably installed on the The inside of the screening box 1; the tail ends of the primary sieve plate 3 and the secondary sieve plate 4 are fixed with a blanking plate 12, and the blanking plate 12 is located directly above the frying box 13, and the frying box 13 A mixing and frying mechanism is provided inside the mixing and frying mechanism, a screen 23 is arranged below the mixing and frying mechanism, and a first slag outlet 24 is provided at th...

Embodiment 2

[0046] Such as figure 1 As shown, in another embodiment provided by the present invention, a group of symmetrically arranged material guide plates 14 are arranged on the upper end of the inside of the frying box 13, and a first automatic telescopic rod 15 is installed symmetrically below the material guide plate 14. , the bottom of the first automatic telescopic rod 15 is fixed on the left and right inner walls of the frying box 13, and the top of the first automatic telescopic rod 15 is fixed with a pressing plate 16.

[0047] The nuts fall under the action of the blanking plate 12, the falling track of the nuts is limited by the material guide plate 14, and the first automatic telescopic rod 15 is started at the same time, and the first automatic telescopic rod 15 drives the pressing plate 16 to move closer to the middle. The shells of the nuts are broken, and the broken nuts fall into the mixing and frying mechanism, which is more convenient for frying and flavoring, and im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com