Surface plate structure for bottom of microwave oven chamber

A microwave oven and oven cavity technology, applied in the field of microwave ovens, can solve the problems of increasing user dissatisfaction, unable to cook food, unable to heat food evenly, etc., and achieve the effects of increasing the purchase rate and shortening the cooking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

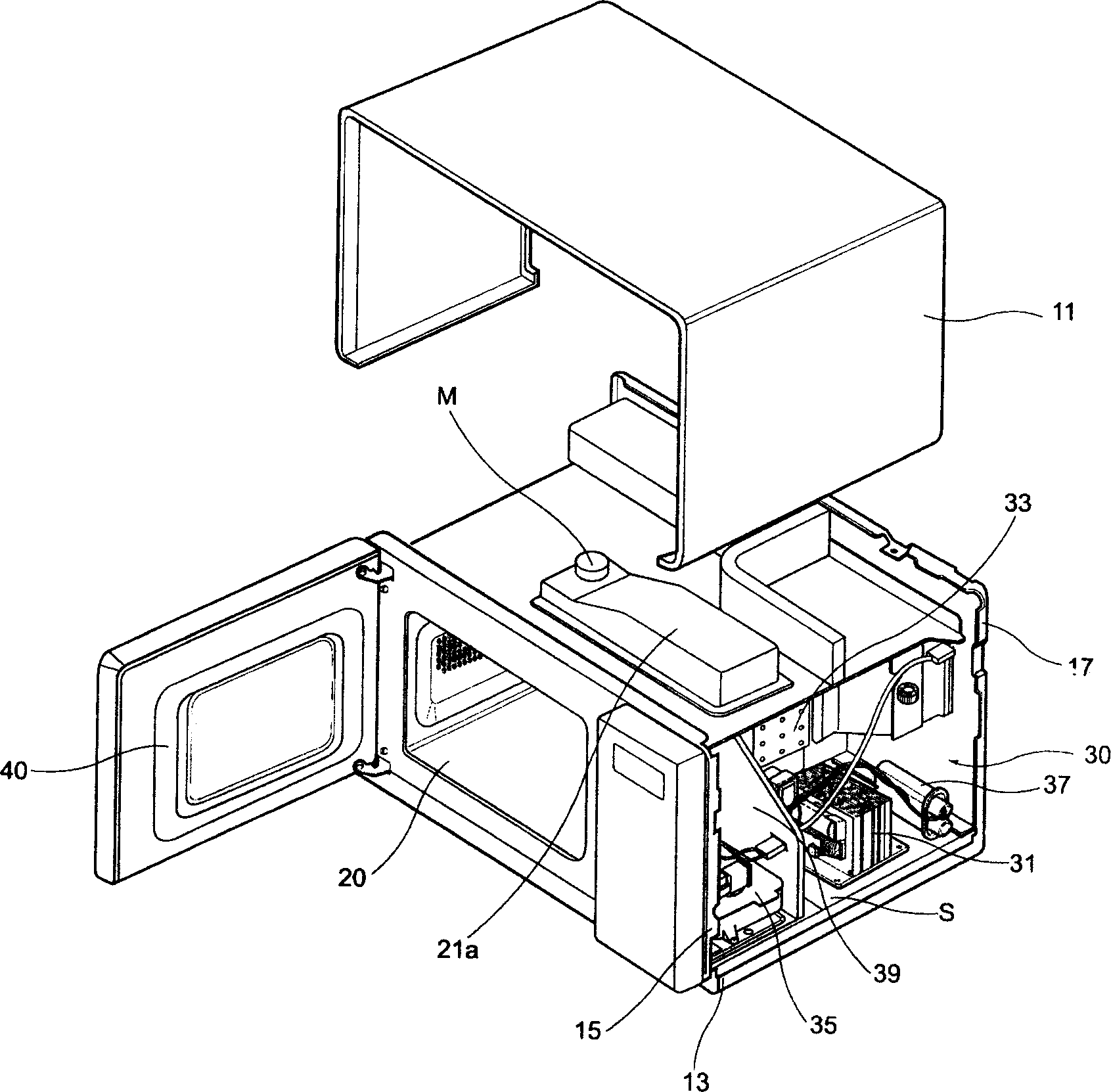

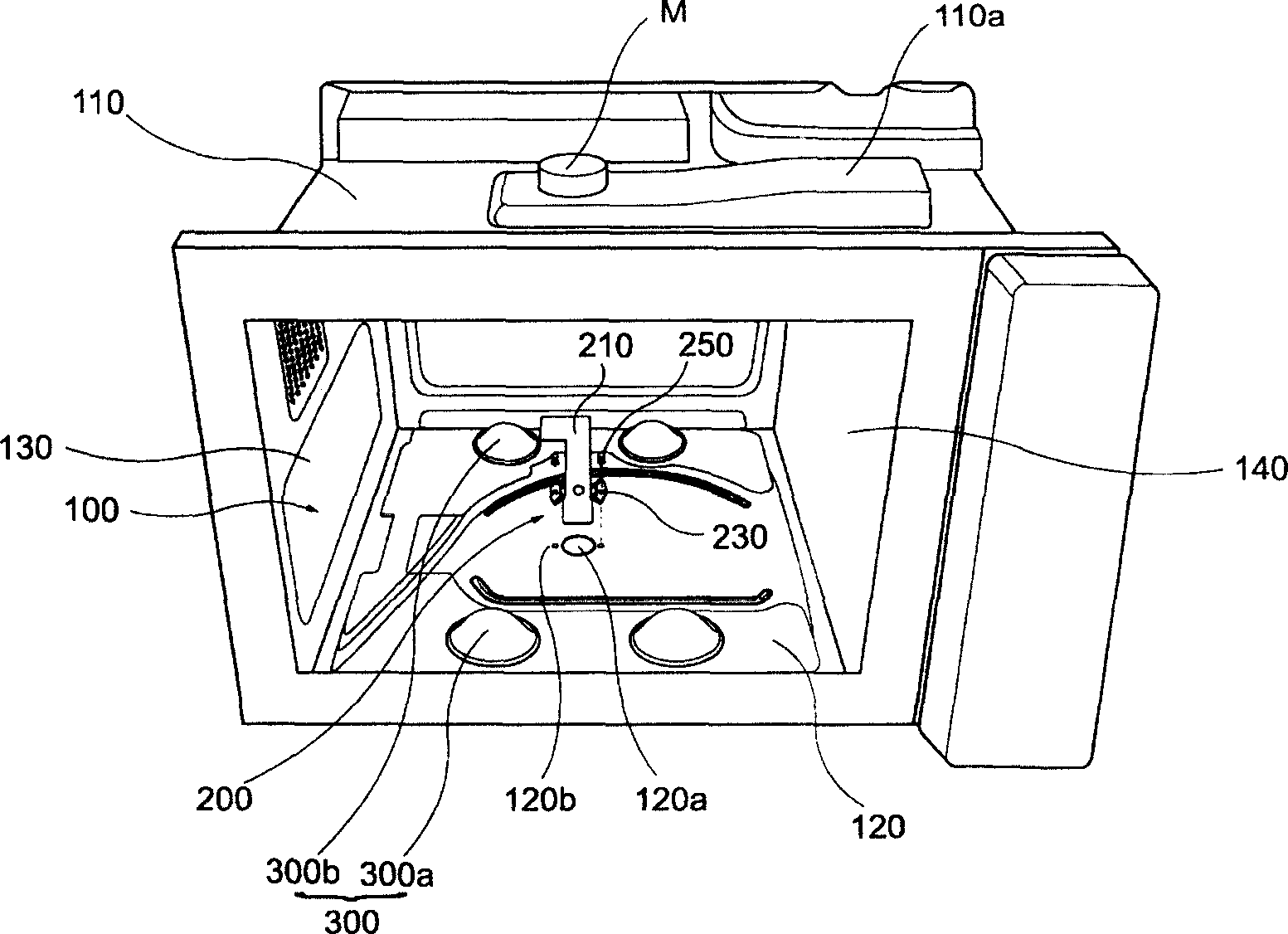

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: image 3 It is an oblique view of the oven cavity of a preferred embodiment of the lower panel structure of the microwave oven cavity of the present invention. As shown in the figure, the oven chamber 100 is roughly shaped like a rectangular box, and has a predetermined space inside for placing food. The oven cavity 100 includes an upper panel 110 disposed above, a lower panel 120 disposed below, a left side panel 130 disposed on the left side, and a right side panel 130 disposed on the right side. Furthermore, the furnace cavity 100 is formed by combining the above panels 110, 120, 130, 140 with each other.

[0045] The above-mentioned upper panel 110 forms the upper surface of the furnace chamber 100, and the waveguide 110a is provided on the outer surface thereof. The waveguide 110a plays a role of guiding the microwave generated by the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com