Biomass hopper briquetting machine

A briquetting machine, biomass technology, applied in the direction of biofuel, material molding press, press, etc., can solve the problem of uneven addition of additives, affecting use, no additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

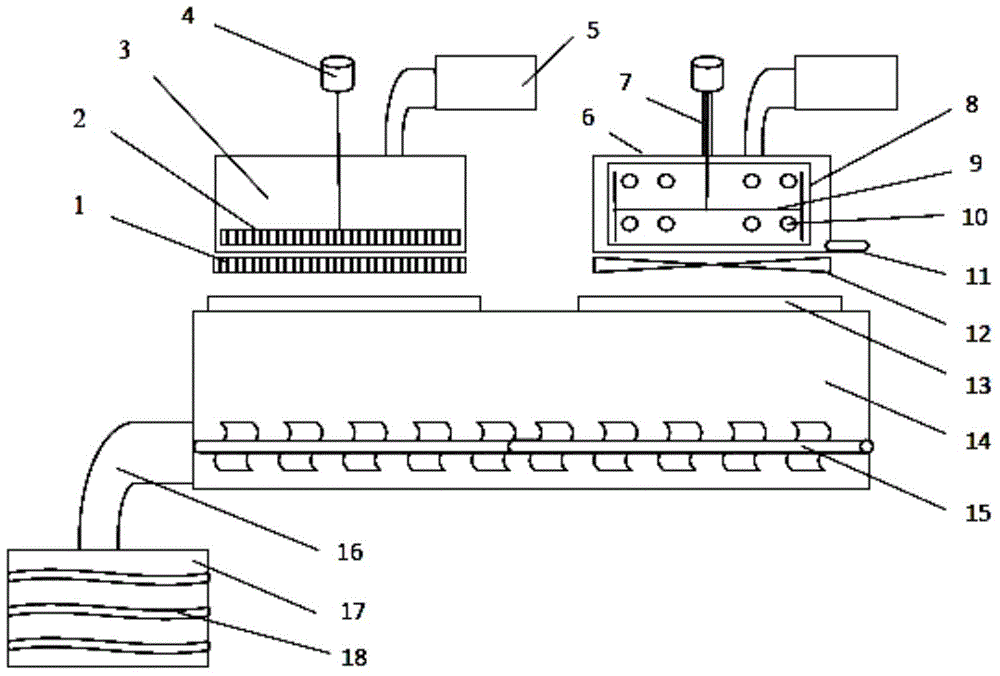

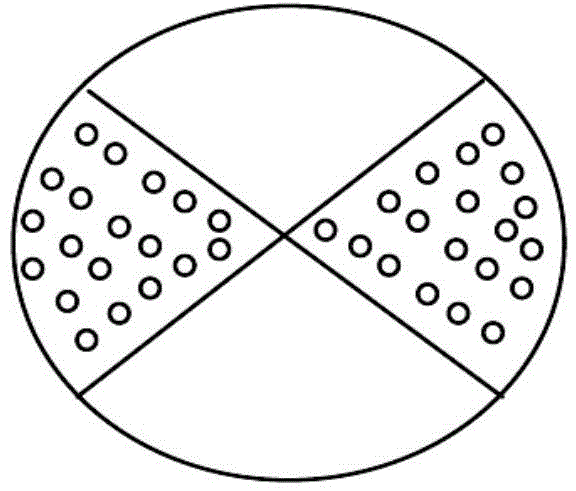

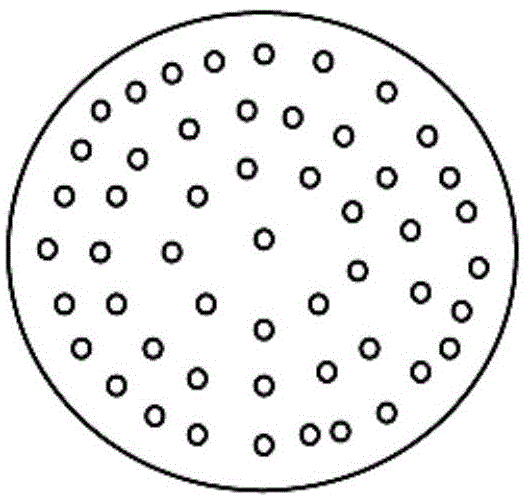

specific Embodiment approach 1

[0009] Embodiment 1: The system is composed of a biomass hopper, an additive hopper, a mixer, and a briquetting machine; the biomass hopper is composed of a feed controller, a mixer, a stirring controller, a dehydration bin, a scraper, and a biomass hopper , drain port, and discharge switch; the feed controller is connected with the biomass hopper, and the biomass hopper is equipped with a mixer and a stirring controller, and the mixer is connected with the dehydration bin and the scraper, and there is a dehydration round hole in the dehydration bin , the scraper is close to the inner wall of the dehydration bin; a dehydration bin is installed inside the biomass hopper, and there is a gap between them. The feed switch is controlled by an infrared controller; the additive hopper is composed of a feed controller, a mixer, an additive hopper, an equalizing pan, and a bottom plate of the additive hopper with round holes; the feed controller is connected with the additive hopper, T...

specific Embodiment approach 2

[0010] This embodiment is based on the specific embodiment 1. The material equalizing pan and the bottom plate of the additive hopper with round holes are all designed as replaceable devices to adjust the size of the holes to produce feed briquettes.

specific Embodiment approach 3

[0011] This embodiment is to adjust the biomass and additives on the basis of the specific embodiment 1, the ratio is 0.5%-99.5%, adding silage feed, palatable agent, trace elements, biological bacteria agent, growth regulator to produce feed briquettes .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com