Method and device for preparing cut expanded plant stems

A technology for stems and plants, applied in the field of processing of plant stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] Taking the tobacco stem as the expansion processing object, the preferred embodiment of the present invention is as follows:

[0027] 1. Remoisturize the tobacco stems, and control the moisture content at 22%-25%.

[0028] 2. The rehydrated tobacco stems are blasted with superheated steam, the pressure temperature of the superheated steam is controlled between 180 and 220 degrees, and the inlet pressure is controlled at 8-10 bar, preferably 9.5 bar.

[0029] 3. Carry out moisture adjustment treatment on the expanded tobacco stems, and control the moisture content at 11%-13% to ensure no agglomeration, so as to facilitate the later screening and shredding treatment.

[0030] 4. The tobacco stems after moisture adjustment are screened, and cut into filamentous stems by a double-roller slitting machine.

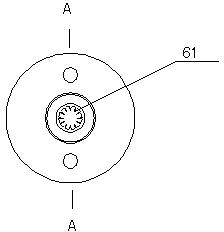

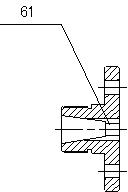

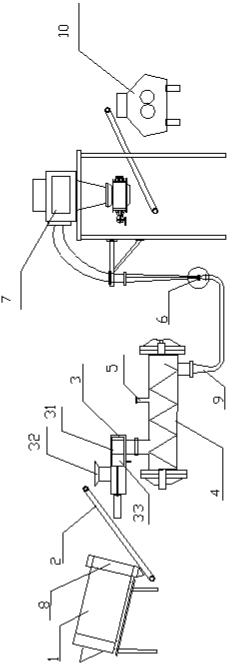

[0031] Such as figure 1 As shown, as a preferred solution, the equipment system of the present invention includes a dampening barrel 1, a conveyor belt 2, a piston typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com