Production process of waterproof willow

A production process and willow technology, applied in the field of willow handicrafts, can solve the problems affecting the use and beauty, affecting the bonding effect, poor paint adhesion, etc., and achieve the effects of excellent mechanical properties, excellent waterproof performance, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

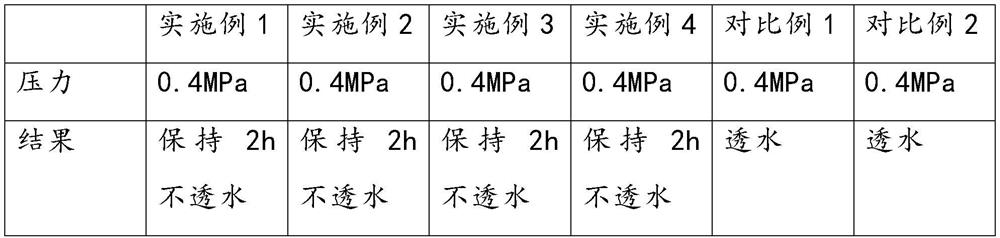

Examples

Embodiment 1

[0022] A kind of production technology of waterproof willow, comprises the steps:

[0023] Step S1, adding KH550 into dichloromethane, stirring at a high speed for 15 minutes, raising the temperature to 45°C, adding willow, soaking for 1 hour, filtering and drying to obtain treated willow;

[0024] Step S2, place the treated willow in a vacuum pressurized tank, pressurize after vacuuming, pump in the composition during the pressurization process, pressurize to 0.5MPa, keep the pressure until the pressure drops to 0MPa, and pressurize again to 0.5MPa, keep warm for 10min, repeat 3 times, and make strengthened willow;

[0025] Step S3: Heat the polyether diol N-220 to 110°C at -0.10MPa, heat and dehydrate for 3h, then slowly add 2,4-toluene diisocyanate dropwise, and control the temperature of the system at 40°C during the dropping process. After the dropwise addition, the temperature was raised to 75°C, reacted for 3 hours, and cooled to room temperature after the reaction, to...

Embodiment 2

[0030] A kind of production technology of waterproof willow, comprises the steps:

[0031] Step S1, adding KH550 into dichloromethane, stirring at a high speed for 15 minutes, raising the temperature to 45°C, adding willow, soaking for 1 hour, filtering and drying to obtain treated willow;

[0032] Step S2, place the treated willow in a vacuum pressurized tank, pressurize after vacuuming, pump in the composition during the pressurization process, pressurize to 0.5MPa, keep the pressure until the pressure drops to 0MPa, and pressurize again to 0.5MPa, keep warm for 10min, repeat 3 times, and make strengthened willow;

[0033] Step S3: Heat the polyether diol N-220 to 110°C at -0.10MPa, heat and dehydrate for 3h, then slowly add 2,4-toluene diisocyanate dropwise, and control the temperature of the system at 40°C during the dropping process. After the dropwise addition, the temperature was raised to 75°C, reacted for 3 hours, and cooled to room temperature after the reaction, to...

Embodiment 3

[0038] A kind of production technology of waterproof willow, comprises the steps:

[0039] Step S1, adding KH550 into dichloromethane, stirring at high speed for 15 minutes, raising the temperature to 50°C, adding willow, soaking for 1 hour, filtering and drying to obtain treated willow;

[0040] Step S2, place the treated willow in a vacuum pressure tank, pressurize after vacuuming, pump the composition during the pressurization process, pressurize to 1.0MPa, keep the pressure until the pressure drops to 0.1MPa, and pressurize again To 1.0MPa, keep warm for 10min, repeat 3 times, and make strengthened willow;

[0041]Step S3: Heat the polyether diol N-220 to 110°C at -0.10MPa, heat and dehydrate for 3h, then slowly add 2,4-toluene diisocyanate dropwise, and control the temperature of the system at 45°C during the dropping process. After the dropwise addition, the temperature was raised to 75°C, reacted for 3 hours, and cooled to room temperature after the reaction to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com