A method and device for preparing a spray solution

A spraying device and a technology of spraying solution, applied in the field of solution preparation, can solve the problems of insufficient puffing, material waste, and inability to improve the release of nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

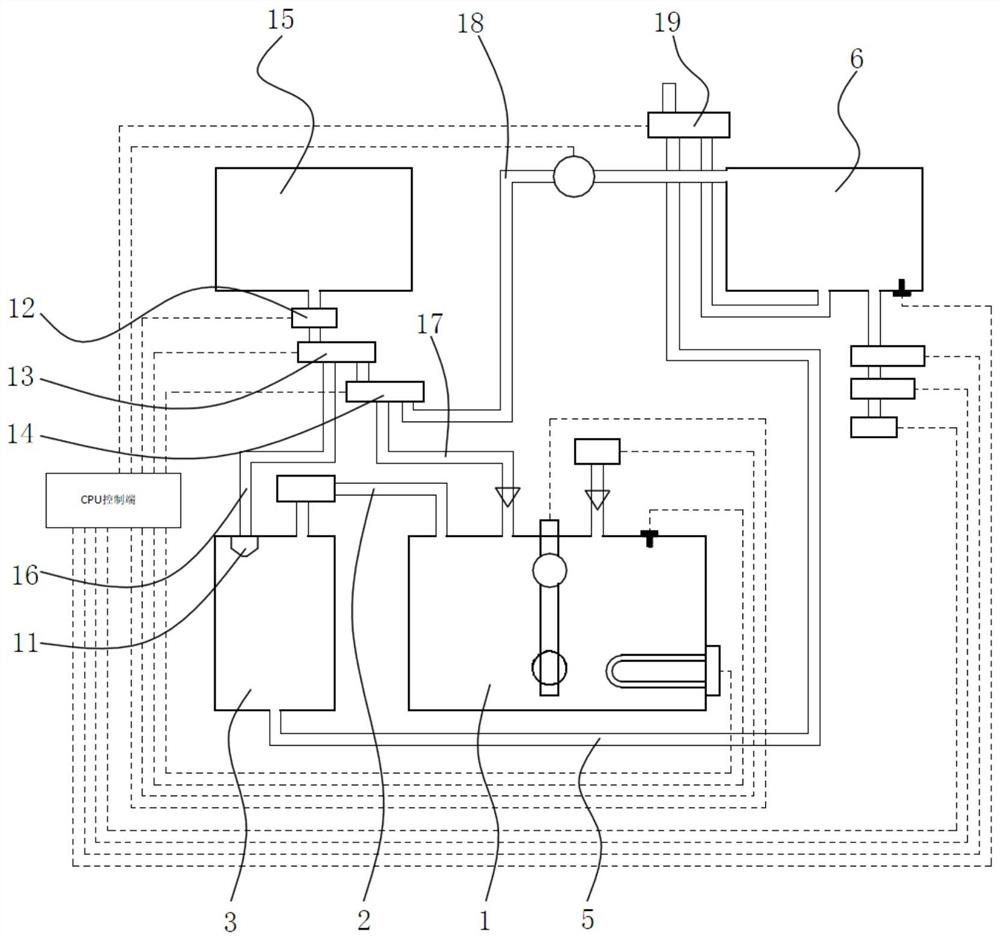

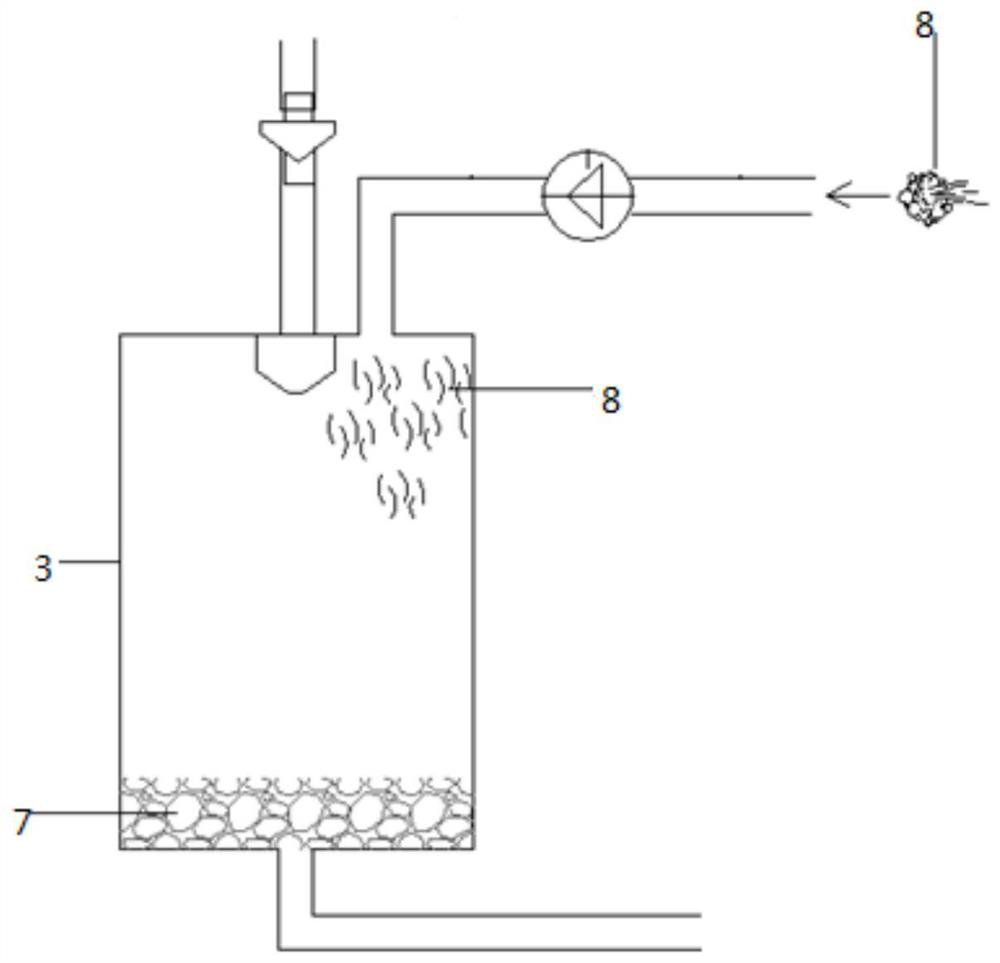

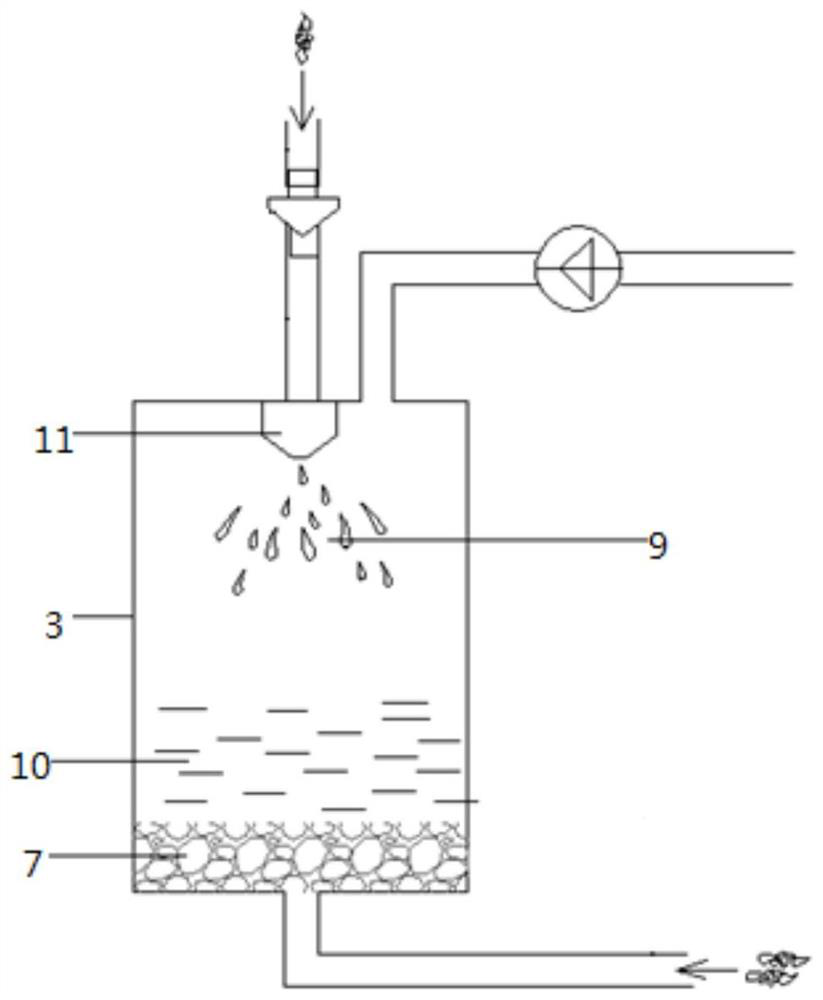

[0030] In this example, if figure 1 Shown is a schematic diagram of the overall working principle of the spray solution preparation device of this embodiment. In the illustration, a steam generator 1 for generating steam is included. The steam generation module is the steam generator 1, and the steam outlet of the steam generator 1 passes through the first A pipe 2 is connected to the material chamber 3, and the steam generator generates steam by heating the water inside it, and the steam is sent to the material chamber through the pipe, and the liquid preparation material to be prepared is stored in the material chamber 3, and the material chamber 3 has An outlet, which extends below the liquid level of the solution container 6 through the second pipeline 5, and a spray device for rapidly forming negative pressure to produce cold boiling is provided in the material chamber 3.

[0031] The basic process of the whole work of the spray solution preparation device in this impleme...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, the steam generation module is a heater 24 for heating the material chamber. The heater 24 generates steam by heating the liquid inside the material chamber, and can distill the liquid inside the material chamber.

[0061] When the heater 24 is heated, the solution in the material chamber will generate steam. During work, it is necessary to add liquid to the material chamber in advance. During the heating process, the continuous generation of steam will cause the liquid in the material chamber to be discharged into the solution container 6 , the liquid in the material chamber cannot be completely discharged, and it needs to be retained in an appropriate amount to prevent the material from drying out and becoming mushy. After part of the liquid is discharged, the steam generated will distill the food. After a period of distillation, in order to prevent all the water from being discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com