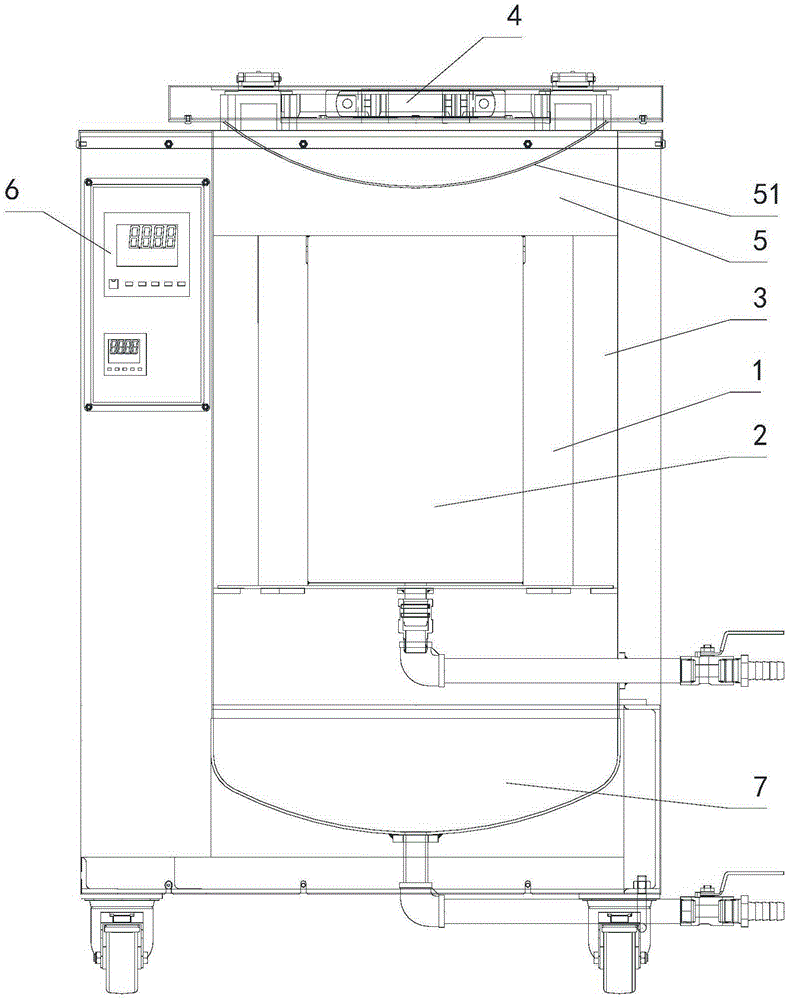

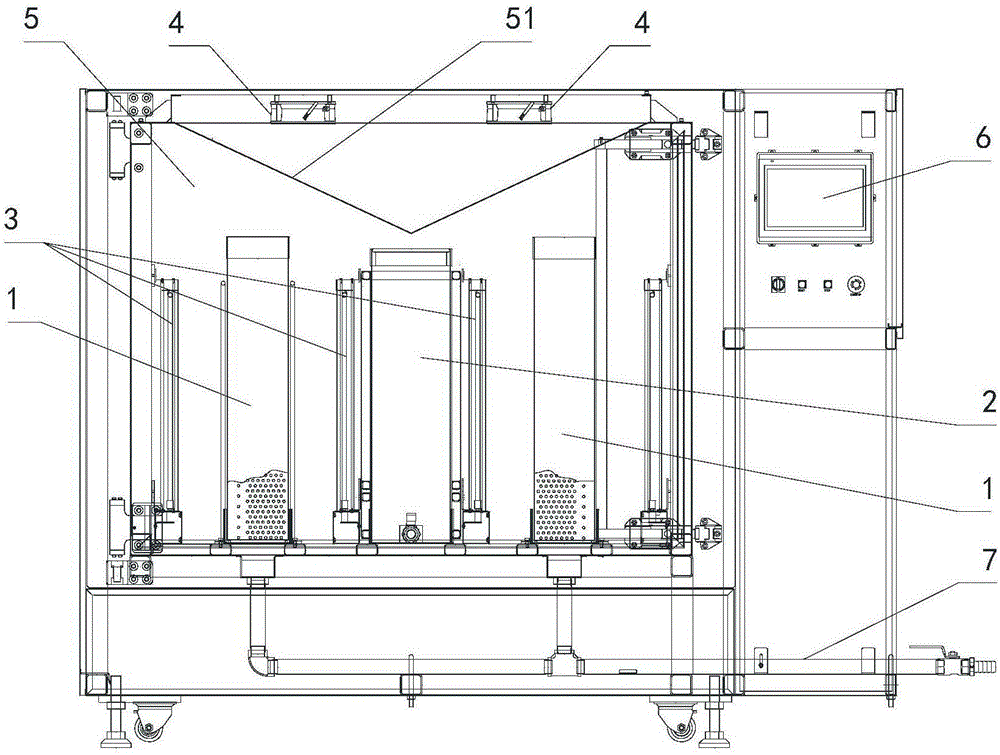

Heterogeneous and synchronous ultramicro original liquid extraction method and apparatus thereof

A technology of out-of-phase synchronous ultramicro and original dew extraction, applied in separation methods, chemical instruments and methods, evaporation, etc., can solve problems such as destruction and achieve the effect of protecting nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 10kg of fresh pine needles is heated to 230°C by high-frequency electromagnetic vibration, and the heating process is completed in 200s;

[0058] Cool the upper part of the plant to keep the temperature at 20-25 ° C, the upper part and the lower part form convection, and form a vacuum negative pressure environment, the pressure of the formed vacuum negative pressure is -0.08 ~ -0.09MPa;

[0059] Lower the temperature of the plants to the first temperature, the first temperature is 90°C, and keep it for 26 hours; then raise the temperature of the plants to the second temperature, the second temperature is 115°C, and keep it for 4 hours; during this process, the steam evaporates continuously, and the Condensation in the upper cooling part;

[0060] Collect the condensate in the upper cooling part to obtain the extract; the extracted pine needles are dry fibrous tissue and oil residue containing heavy metal pesticide residues.

[0061] Obtain 6kg of extracting liquid, thi...

Embodiment 2

[0063] Heat 4kg of fresh jasmine flowers to 190°C by high-frequency electromagnetic vibration, and the heating process is completed in 100s;

[0064] Cool the upper part of the plant to keep the temperature at 15-20 ° C, the upper part and the lower part form convection, forming a vacuum negative pressure environment, and the pressure of the formed vacuum negative pressure is -0.09 ~ -0.10MPa;

[0065] The temperature of the plants is lowered to the first temperature, the first temperature is 75°C, and kept for 16h; then the temperature of the plants is raised to the second temperature, the second temperature is 85°C, and kept for 1h; Condensation in the cooling part;

[0066] The extract is obtained by collecting the condensate in the upper cooling part; the extracted jasmine is dry fibrous tissue and oil residue containing heavy metal pesticide residues.

[0067] Obtain 2.8 kg of extract, which is mainly composed of essential oil and jasmine cell fluid, with a yield of 70%....

Embodiment 3

[0069] Heat 4kg of fresh mint to 180°C by high-frequency electromagnetic vibration, and the heating process is completed in 150s;

[0070] Cool the upper part of the plant to keep the temperature at 15-20 ° C, the upper part and the lower part form convection, and form a vacuum negative pressure environment, the pressure of the formed vacuum negative pressure is -0.08 ~ -0.09MPa;

[0071] Reduce the temperature of the plants to the first temperature, the first temperature is 80°C, and keep for 10h; then raise the temperature of the plants to the second temperature, the second temperature is 90°C, and keep for 1h; during this process, the steam evaporates continuously, and the Condensation in the upper cooling part;

[0072] The extract is obtained by collecting the condensate in the upper cooling part; the mint after extraction is dry fibrous tissue and oil residue containing heavy metal pesticide residues.

[0073] Obtain 2.6 kg of extract, which is cell fluid mainly compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com