Puffed crispy glutinous rice chips with various tastes and production method thereof

A technology for puffed glutinous rice and a production method, applied in the application, food preparation, food science and other directions, can solve the problems of high investment, maintenance and operation costs, hinder the absorption of oil and protein, reduce the nutritional value of food, etc., and achieve controllable product quality. It has strong properties, is conducive to the application and promotion of technology, and has the effect of short microwave puffing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

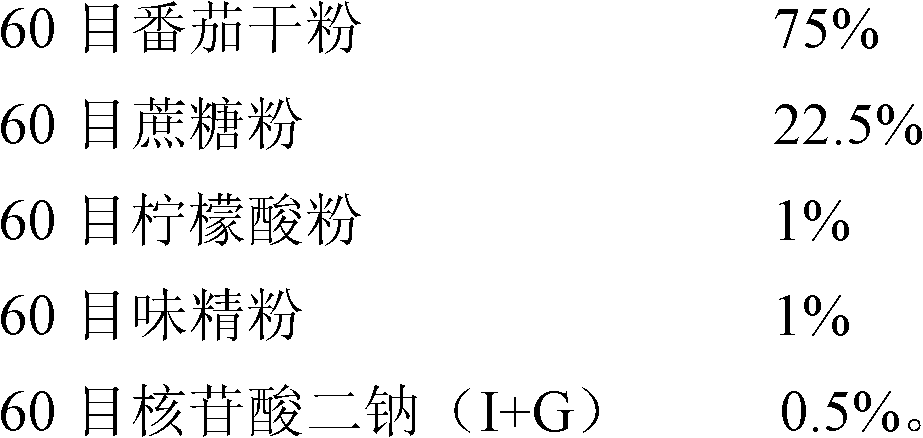

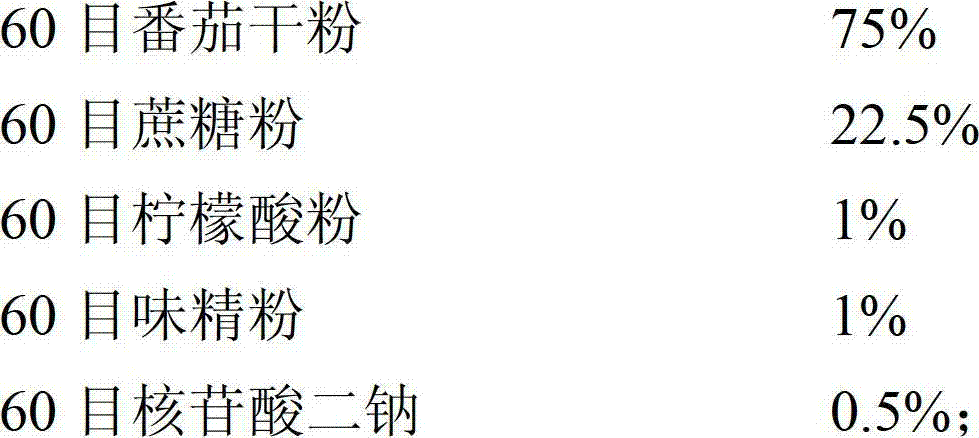

[0039] The preparation method of tomato-flavored puffed glutinous rice crispy strips is as follows:

[0040] (1) Preparation of dough: take 10kg of 80-mesh glutinous rice flour (water mass content is 13%), add 0.3kg of 60-mesh white sugar powder, 0.25kg peanut oil, mix well, add 6.3kg of water, and stir in SZM-40 mixer for 10min , stir to form a dough.

[0041] (2) Gelatinization: Press the dough into a dough sheet with a thickness of 10mm, and cook it in water for 50 minutes, so that the starch can fully absorb water, swell and gelatinize, and the dough sheet becomes viscous and transparent.

[0042] (3) Roller kneading: Cool the cooked noodles to 35°C, and then use the SZM-40 mixer to stir the rollers for 15 minutes to make the dough evenly mixed.

[0043] (4) Hardening: Roll the dough kneaded by the roller into a dough sheet with a thickness of 15mm with a B.P.560 rolling mill, and refrigerate and harden at 4°C for 30 hours.

Embodiment 2

[0053] The preparation method of the sweet puffed glutinous rice crispy strips is as follows:

[0054] (1) Prepare dough: take 10kg 80 mesh glutinous rice flour (moisture mass content is 13%), add 0.3kg soybean protein isolate, 0.65kg 60 mesh white granulated sugar powder, mix evenly, then add 8.2kg water, mix in SZM-40 mixer Stir well within 15 minutes to form a dough.

[0055] (2) Gelatinization: Press the dough into a dough sheet with a thickness of 5 mm, and cook it in water for 20 minutes to make the starch fully absorb water and swell and gelatinize, and the dough sheet becomes sticky and transparent.

[0056] (3) Roller kneading: Cool the steamed noodles to 50°C, and then use the SZM-40 mixer to knead for 15 minutes to form a dough evenly.

[0057] (4) Hardening: Roll the kneaded dough with a B.P.560 rolling mill into a dough sheet with a thickness of 10mm, and refrigerate and harden at about 8°C for 18 hours.

Embodiment 3

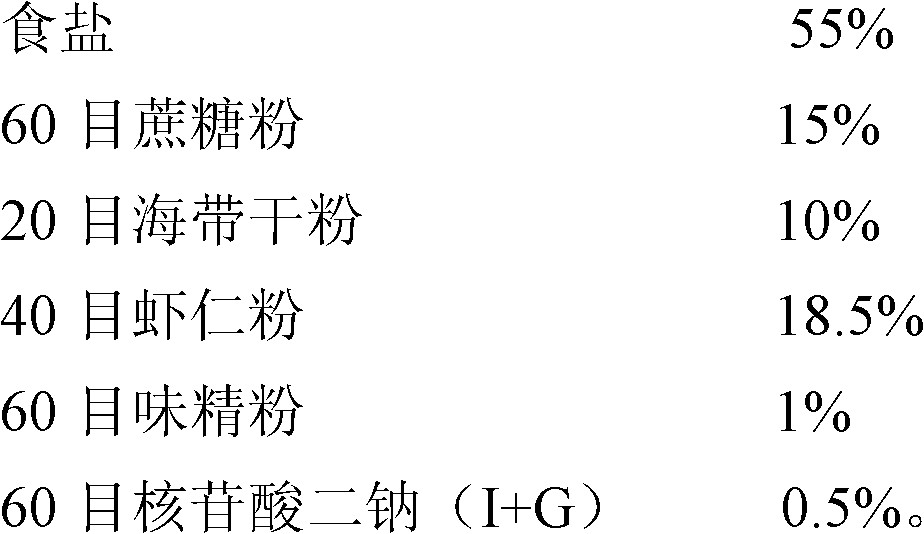

[0067] The preparation method of seafood-flavored puffed glutinous rice crispy strips is as follows:

[0068] (1) Prepare dough: take 10kg 80 mesh glutinous rice flour (moisture mass content is 13%), add 0.1kg soybean protein isolate, 0.55kg peanut oil and 0.1kg salt, mix well, then add 7.5kg water, in SZM-40 Fully stir in the mixer for 12 minutes to form a dough.

[0069] (2) Gelatinization: Press the dough into a dough sheet with a thickness of 8 mm, and cook it in water for 40 minutes to make the starch fully absorb water and swell and gelatinize, and the dough sheet becomes sticky and transparent.

[0070] (3) Roller kneading: Cool the steamed noodles to 40°C, then use the SZM-40 mixer to knead for 10 minutes to form a dough evenly.

[0071] (4) Hardening: Roll the kneaded dough with a B.P.560 rolling mill into a dough sheet with a thickness of 20 mm, and refrigerate and harden at 6°C for 25 hours.

[0072] (5) Slicing: cut the hardened noodles into rice blanks with a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com