Expanded-feed processing system and processing technology

A technology of extruded feed and processing system, applied in feed, chemical instruments and methods, solid separation, etc., can solve the problems of poor feed quality and low feed efficiency, and achieve convenient extrusion and packaging, ensure processing efficiency, and prevent clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

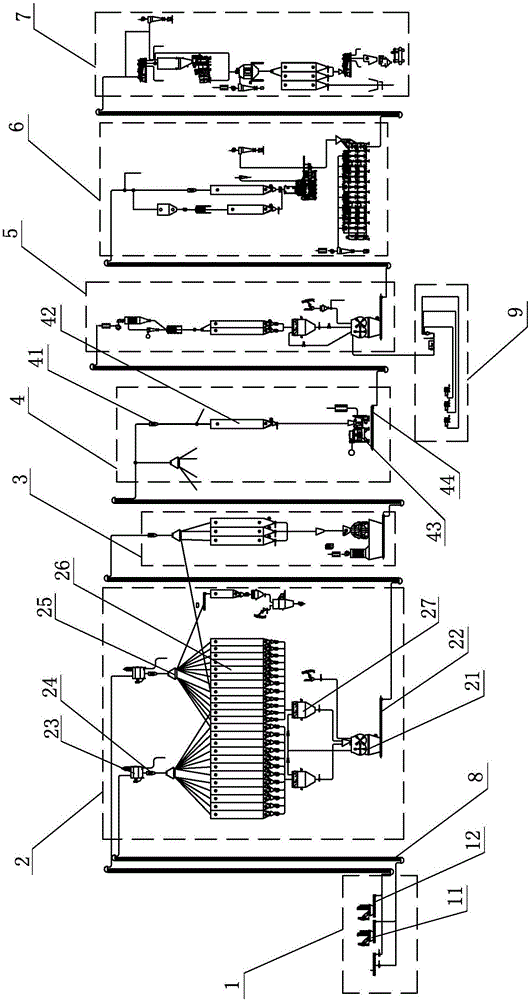

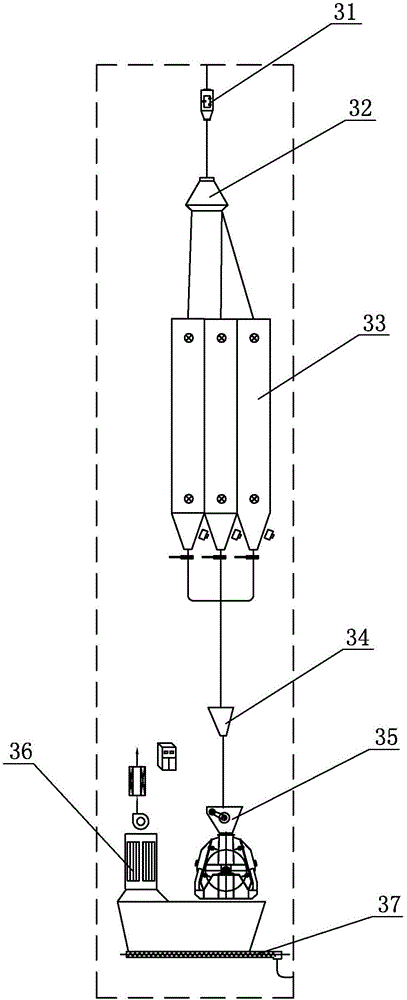

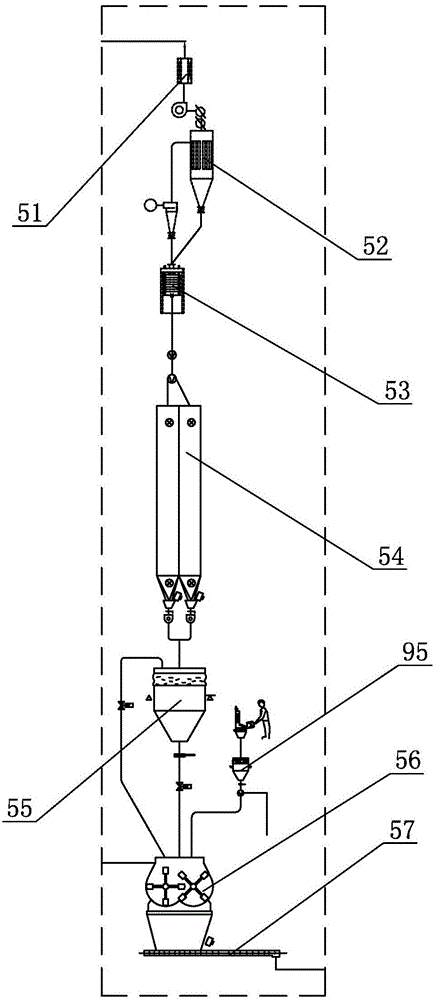

[0031] Embodiment one: see Figure 1~6 As shown, an extruded feed processing system includes a raw material receiving system 1, a primary ingredient mixing system 2, a primary crushing system 3, an ultrafine grinding system 4, a secondary ingredient mixing system 5, an extruded drying system 6 and an extruded material packaging system 7. The raw material receiving system, the primary ingredient mixing system, the primary crushing system, the superfine crushing system, the secondary ingredient mixing system, the puffing drying system and the puffing material packaging system are respectively connected via a raw material hoist 8 .

[0032] In this embodiment, the raw material receiving system is used to receive raw materials. The primary batching system batches the raw materials once, and then the primary crushing system crushes the materials after the primary batching to a certain particle size. In the process of material crushing, the material can be further mixed to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com