Method for manufacturing light GMT sheet material

A sheet, lightweight technology, used in non-woven fabrics, textiles and papermaking, fiber processing, etc., can solve the problems of difficult bonding between resin matrix and glass fiber interface, high resin melt viscosity, and difficult thermal impregnation. Fast production speed, light weight and high rigidity for sound insulation, good impregnation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

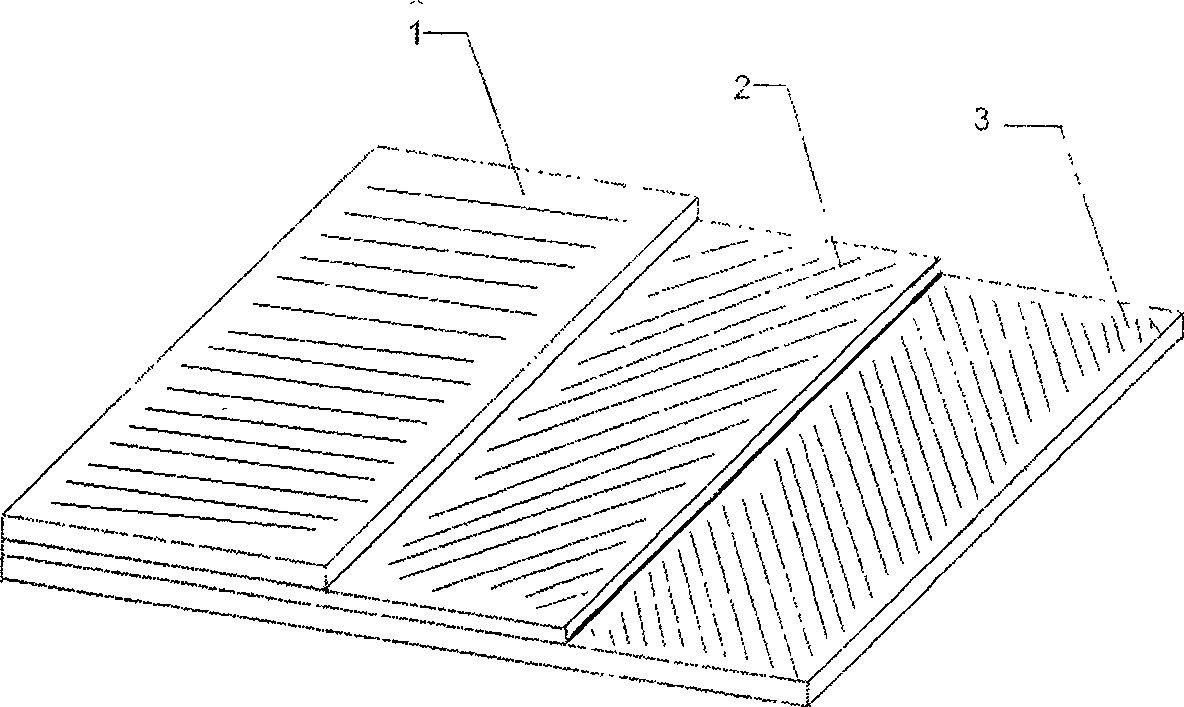

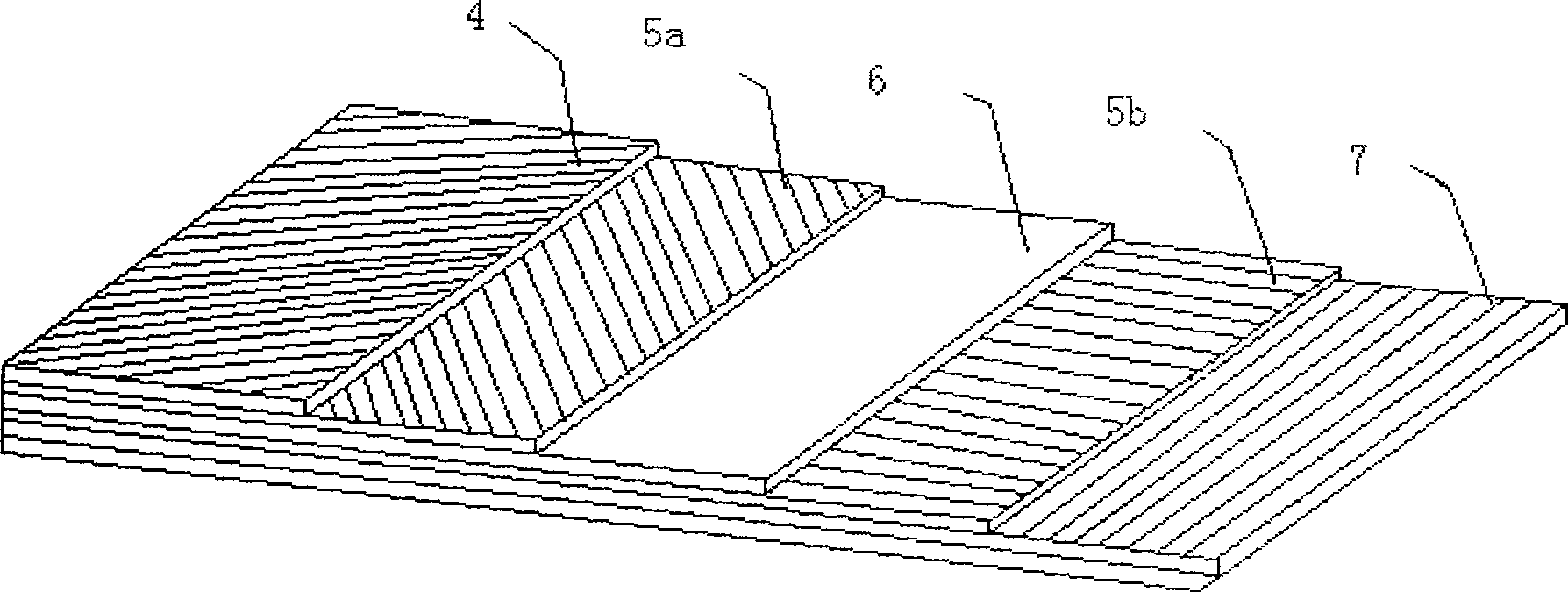

[0027] figure 2 For the structural representation of the lightweight GMT plate prepared by the present invention, refer to figure 2 , the lightweight GMT sheet includes: a surface covering layer 4, an intermediate layer 5a, 5b, a sandwich layer 6, and a bottom layer 7, wherein the intermediate layer is electrostatic dry impregnated glass fiber chopped strand mat (mixed mat), and the sandwich layer is selected from thermoplastic glass One of the roll materials such as fiber cotton, honeycomb foam material, thin aluminum sheet, etc., the bottom layer is non-woven fabric.

[0028] The specific implementation process is shown in the following examples:

Embodiment 1

[0030] Produce lightweight GMT panels for car roofs.

[0031] (1) Material preparation: ① According to the above product requirements, produce 1 roll of E-glass fiber chopped chopped mixed mat uniformly impregnated by electrostatic dry method (specification: 1050g / m 2 , 60m long, width 1.32m), ②PP film 60m (50g / m 2 , width 1.3m), ③ polyester non-woven fabric 60m (100g / m 2 , width 1.3m);

[0032] (2) E-glass fiber chopped chopped mixed mat uniformly impregnated by unwinding electrostatic dry method;

[0033] (3) The alkali-free glass fiber chopped mixed mat uniformly impregnated by electrostatic dry method is baked, plasticized and melted at low temperature (120-140°C), medium temperature (140-170°C) and high temperature (170-210°C) in an oven. Melt impregnation. In the oven, the running speed of the glass fiber mixed felt is ≤8m / min, and the moisture exhaust outlet is opened at the outlet of the high temperature area to remove the smoke. After the glass fiber mixed felt co...

Embodiment 2

[0036] Production of lightweight GMT panels for passenger compartments.

[0037] (1) Material preparation: ① 2 rolls of E-glass fiber chopped chopped mixed mat uniformly impregnated by electrostatic dry method, each 60m (specification: 600g / m 2 , width 1.1m), ②PP film 60m (50g / m 2 , width 1m), ③ polyester non-woven fabric 60m (50g / m 2 , width 1m)); ④ thermoplastic glass fiber cotton 60m (500g / m 2 , width 1m));

[0038] (2) E-glass fiber chopped chopped mixed mat uniformly impregnated by unwinding electrostatic dry method;

[0039] (3) Unwind thermoplastic fiberglass wool on the impregnated even alkali-free glass fiber chopped strand mat of above-mentioned unwinding according to product structure;

[0040] (4) Unwind the alkali-free glass fiber chopped chopped mixed mat uniformly impregnated by electrostatic dry method on the above-mentioned product;

[0041] (5) The three-layer material is subjected to composite double-sided needling, so that the material is entangled int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com