Textured geocell

a geocell and textured technology, applied in soil conditioning compositions, excavations, applications, etc., can solve the problems of increasing the manufacturing cost of texturized cell materials, the friction between retained geocells b>4/b> and backfills is not large enough to prevent backfill from being washed away, and the retaining capacity of backfills is not enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

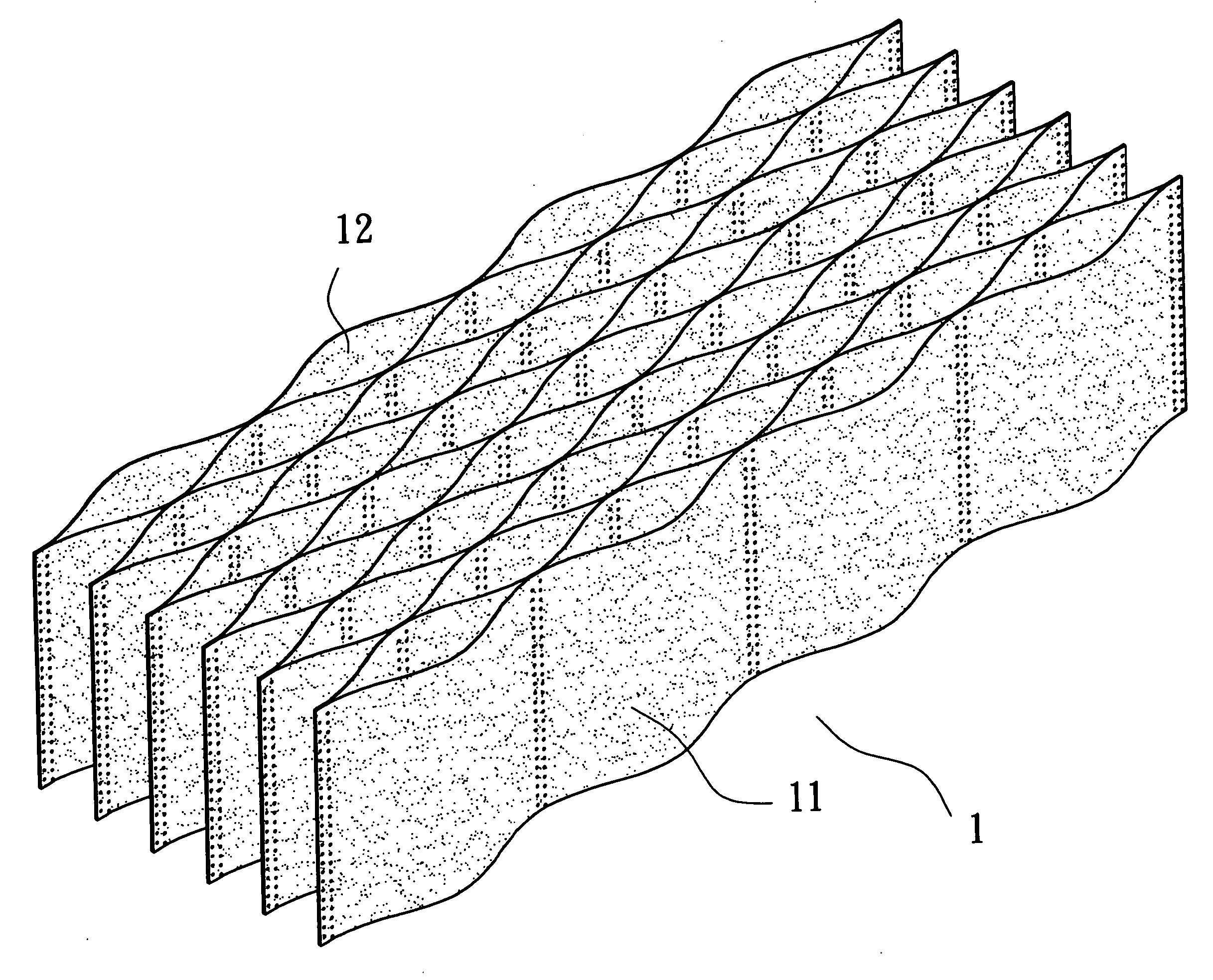

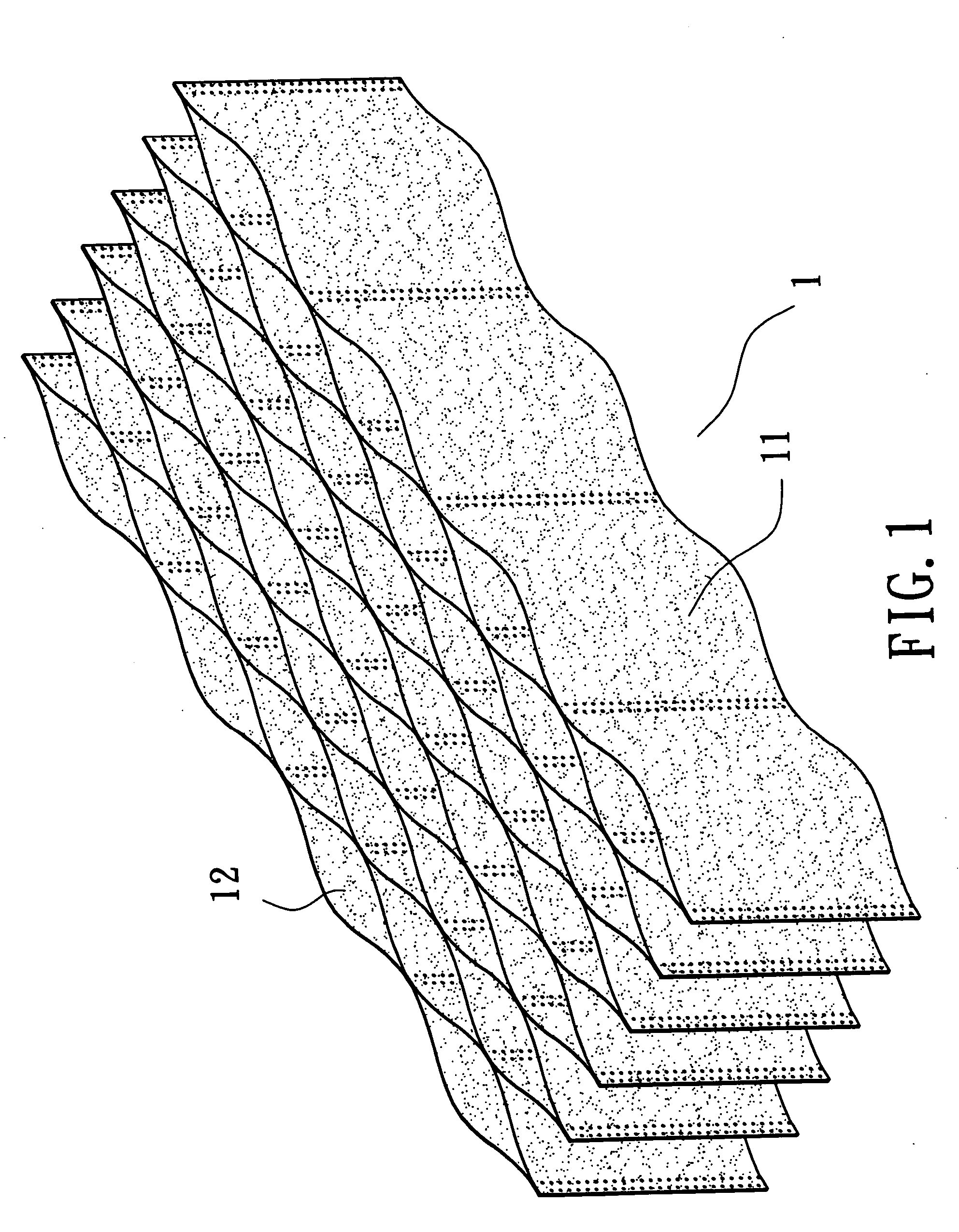

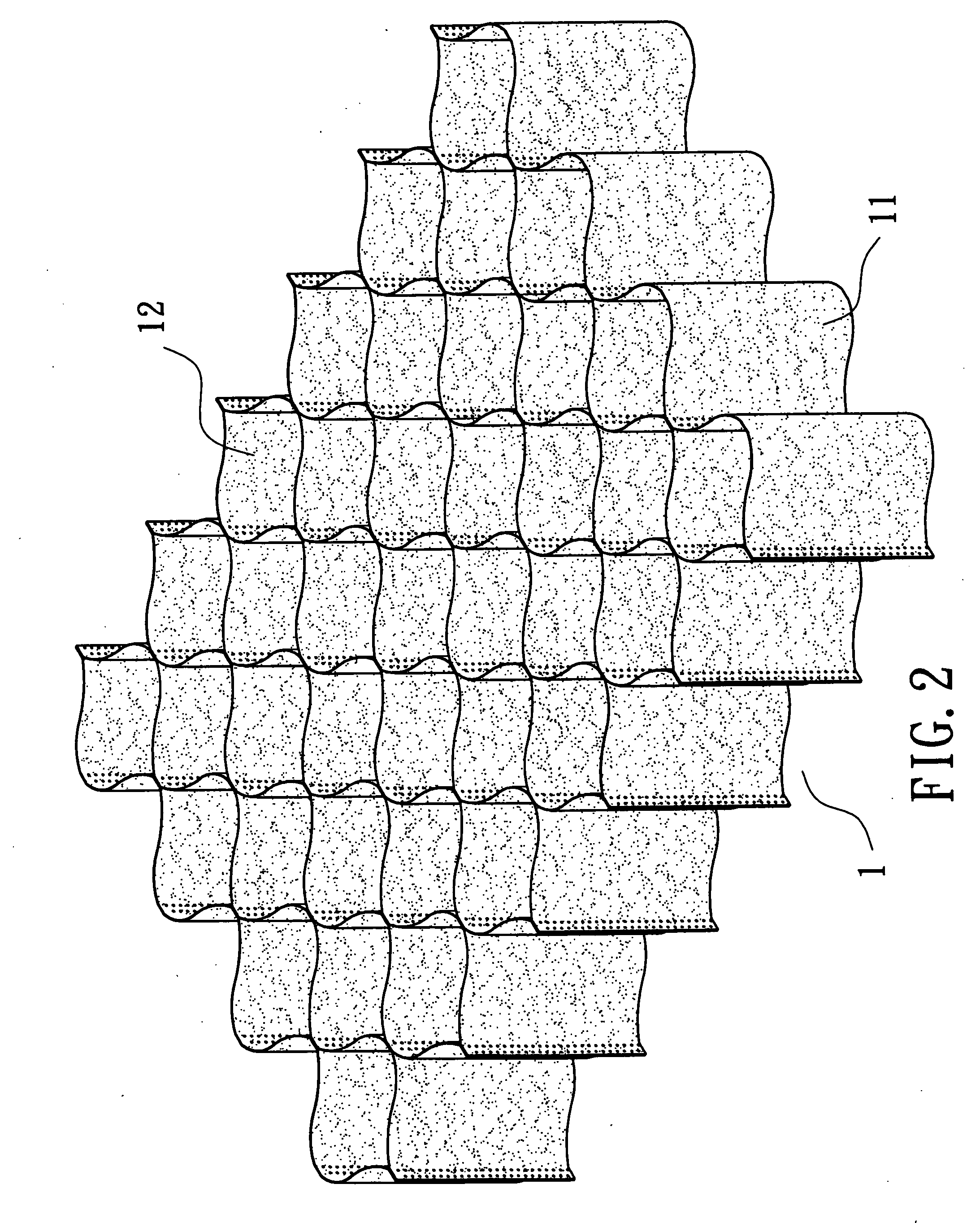

[0023] Referring to FIGS. 1 to 3, a preferred embodiment 1 of a geocell for retaining infill in geotechnical structure includes several plastic plates with rough finishes 11 with irregular projections on both sides. Every two adjacent plastic plates are connected together at several spaced apart elongate joints, each of which elongate joints includes several aligned points, and in turns, the present geocell will be in the shape of a honeycomb, which includes many cells 12 for containing backfill therein, when it is expanded, as shown in FIG. 2; welding with ultrasonic wave or other methods can be used for connecting the plastic plates together. Because the plastic plates have rough finishes 11 with irregular projections, the backfill 2 can be effectively retained in the textured infill retained geocell 1 of the present invention.

[0024] The rough finishes 11 on the plastic plates are made by means of the following steps:

[0025] 1. mixing materials: plastic materials, stains, and proc...

second embodiment

[0033] Referring to FIG. 7, in a second embodiment, the plastic plates of the textured geocell 1 are further formed with several through holes 13 over them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com