Heavy metal precipitating agent

A heavy metal precipitation and weight technology, applied in the field of precipitant, can solve the problems of weak complexation ability, loose floc sedimentation speed, low raw material utilization rate, etc., and achieve the effect of improving precipitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

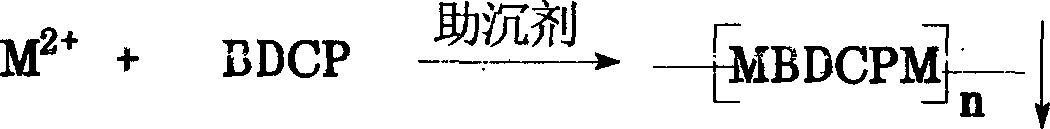

Method used

Image

Examples

Embodiment 1

[0024] Add 9.5mg BDCP to 50ml containing Cu 2+ 50mg.l -1 In the CuSO4 wastewater, the speed is 85rmin -1 After stirring with the mixer for 5 minutes, a brown precipitate appeared in the wastewater solution. After standing still for 4 hours, the turbidity of the measured solution was 42, and the residual Cu in the solution 2+ The concentration is 0.6mg.l -1 .

Embodiment 2

[0026] 9.5mg BDCP and 0.1mg Al 2 (SO 4 ) 3 Add 50ml containing Cu 2+ 50mg.l -1 In the CuSO4 wastewater, the speed is 85rmin -1 After 5 minutes of stirring with the mixer, a large amount of precipitation appeared in the waste water. After standing still for 30 minutes, the turbidity of the solution measured was 26, and the residual Cu in the solution was 2+ The concentration is 0.1mg.l -1 , which are all lower than the national comprehensive wastewater discharge standards. Place this precipitate in water with a pH of 6 for 60 days, Cu 2+ The cumulative dissolution concentration is only 0.08mg.l -1 .

Embodiment 3

[0028] 11 mg CSM (45% by weight N, N-sodium dithiopiperazine formate, 53% by weight activated carbon powder, 1.0% by weight Al 2 (SO4) 3 and 1.0% by weight MgSO4) add 50ml containing Cu 2+ 50mg.l -1 In the CuSO4 wastewater, the speed is 85rmin -1 After 5 minutes of stirring with the mixer, a large amount of precipitation appeared in the waste water. After standing still for 30 minutes, the turbidity of the solution measured was 16, and the residual Cu in the solution 2+ The concentration is 0.07mg.l -1 , which are all lower than the national comprehensive wastewater discharge standards. Place this precipitate in water with a pH of 6 for 60 days, Cu 2+ The cumulative dissolution concentration is only 0.079mg.l -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com