Composite fibrous membrane having hydrophobic/hydrophilic wettability difference and preparation method thereof

A composite fiber membrane, wettable technology, used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problem of failure to functional research, impermeability from hydrophilic side to hydrophobic side, and stability to be further Improve and other problems, to achieve the effect of efficient capture and collection capacity, simple preparation method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Heat and stir the analytically pure polymer polyacrylonitrile (PAN) at 60°C until it dissolves in N,N-dimethylformamide (DMF) solvent, and stir until the PAN is completely dissolved to obtain polyacrylonitrile Electrospinning solution A of N,N-dimethylformamide (PAN / DMF). The mass fraction of the obtained electrospinning solution A was 12.5 wt%.

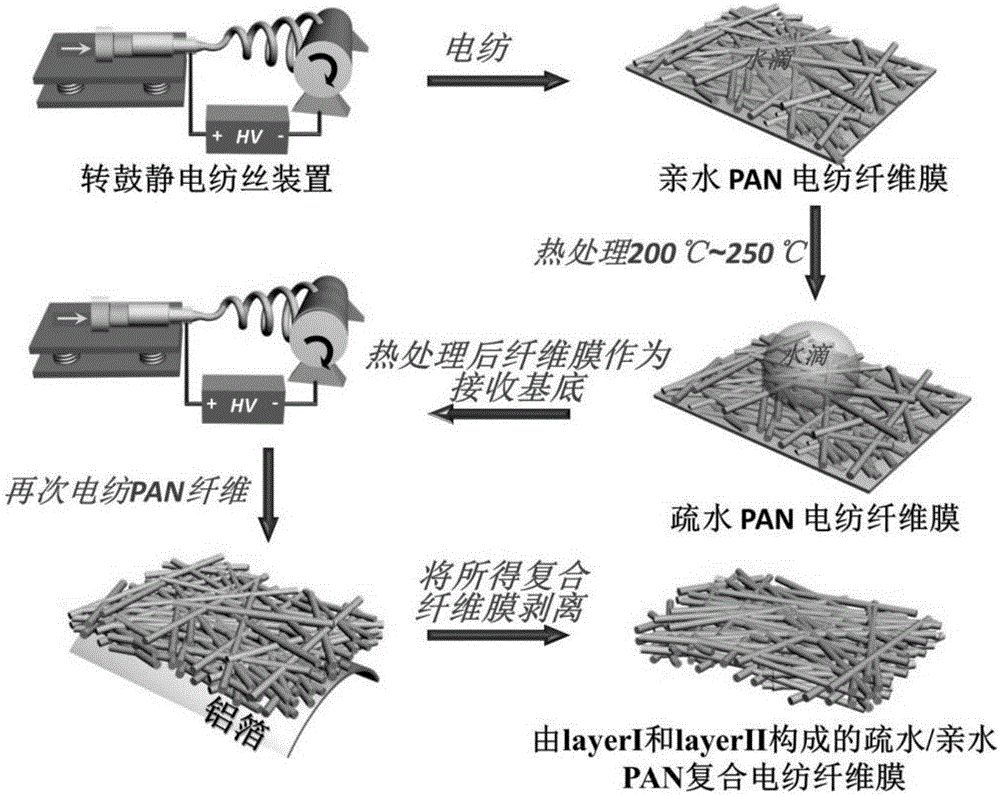

[0025] (2) The electrospinning solution A is placed in the syringe of the electrospinning equipment, and a high-voltage electrostatic field is applied between the metal spinneret of the syringe and the drum receiving base, the high-voltage electrostatic field voltage is 10kV, and the diameter of the metal spinneret is 0.4mm, the rotating speed of the drum is 100r / min, and the receiving substrate A is aluminum foil. The preparation process is as figure 1 As shown, a drum electrospinning device was used. Adjust the distance between the metal spinneret and the receiving base of the drum to be 10 cm, and the applied high-vo...

Embodiment 2

[0031] (1) Heat and stir the analytically pure polymer polyacrylonitrile (PAN) at 100°C until it dissolves in N,N-dimethylformamide solvent, and stir fully until the polymer is completely dissolved to obtain polyacrylonitrile / N , Electrospinning solution A of N-dimethylformamide (PAN / DMF). The mass fraction of the obtained electrospinning solution A was 20 wt%.

[0032] (2) The above-mentioned PAN / DMF electrospinning solution A is placed in the syringe of the electrospinning equipment, and a high-voltage electrostatic field is applied between the metal spinneret of the syringe and the drum receiving substrate. The voltage of the high-voltage electrostatic field is 35kV, and the metal spinneret The diameter of the head is 1.8mm, the rotational speed of the drum is 2000r / min, and the receiving substrate A is aluminum foil. Adjust the distance between the metal spinneret and the receiving substrate of the drum to 30cm, and apply a high-voltage electrostatic field to make the PAN...

Embodiment 3

[0038] (1) Heat and stir the analytically pure polymer polyacrylonitrile (PAN) at 85°C until it dissolves in tetrahydrofuran (THF) solvent, and fully stir until PAN is completely dissolved to obtain polyacrylonitrile / tetrahydrofuran (PAN / THF) Electrospinning solution A. The mass fraction of the obtained electrospinning solution A was 17.5 wt%.

[0039] (2) Place the electrospinning solution A of the above-mentioned PAN / THF in the syringe of the electrospinning equipment, apply a high-voltage electrostatic field between the metal spinneret of the syringe and the receiving base of the drum, the voltage of the high-voltage electrostatic field is 20kV, and the metal spraying The diameter of the wire head is 0.8mm, the rotating speed of the drum is 1000r / min, and the receiving substrate A is aluminum foil. Adjust the distance between the metal spinneret and the receiving base of the drum to be 15 cm, and the applied high-voltage electrostatic field causes the PAN / THF electrospinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com