Bi*WO*/oxide fiber cloth with multistage heterogeneous structure, method and application

A technology of heterostructures and oxides, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, botanical equipment and methods, etc., to achieve the effects of simple preparation process, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] TiO for electrospinning 2 The precursor sol is composed of polyvinylpyrrolidone (PVP) with a mass concentration of 5%, 20% acetic acid, 20% tetrabutyl titanate and the rest of ethanol, which are stirred and mixed. At room temperature, the above-mentioned precursor sol was added to the electrospinning equipment, so that the precursor was formed as TiO in the injection device 2 Ejection in the form of nanowires, obtaining TiO on the receiving device 2 Fiber cloth composed of precursor nanowires. TiO 2 The precursor fiber cloth was sintered at 500 °C for 2 hours to obtain TiO 2 Fiber cloth.

[0029] Alcohothermal synthesis of Bi 2 WO 6 The precursor used is 0.485g Bi(NO 3 ) 3 ·5H 2 O (analytically pure) and 0.165g Na 2 WO 4 2H 2 O (analytical grade), dissolved in 40mL ethylene glycol. Bi 2 WO 6 Precursors and nano TiO 2 Fiber cloth joins in the alcohol heat kettle, wherein Bi 2 WO 6 Precursor and Nano TiO 2 The mass ratio of the fiber cloth is 800:1. Aft...

Embodiment 2

[0033] TiO for electrospinning 2 The precursor sol is composed of polyvinylpyrrolidone (PVP) with a mass concentration of 8%, 10% acetic acid, 10% tetrabutyl titanate and the rest of ethanol, which are stirred and mixed. At room temperature, the above precursors were added to the electrospinning equipment, so that the precursors were transformed into TiO in the injection device 2 Ejection in the form of nanowires, obtaining TiO on the receiving device 2 Fiber cloth composed of precursor nanowires. TiO 2 The precursor fiber cloth was sintered at 500 °C for 2 hours to obtain TiO 2 Fiber cloth.

[0034] Bi for alcohol thermal synthesis 2 WO 6 The precursor is composed of 0.796g bismuth citrate (analytical pure) and 0.329g Na 2 WO 4 2H 2 O (analytical grade), dissolved in 40mL glycerol. Bi 2 WO 6 Precursors and nano TiO 2 Fiber cloth joins in the alcohol heat kettle, wherein Bi 2 WO 6 Precursor and Nano TiO 2 The mass ratio of the fiber cloth is 100:1. After sealin...

Embodiment 3

[0037] TiO prepared by electrospinning 2 The preparation method of fiber cloth is the same as embodiment 1.

[0038] Bi for alcohol thermal synthesis 2 WO 6 The precursor is composed of 0.323g bismuth oxalate (analytical pure) and 0.066g Na 2 WO 4 2H 2 O (analytical grade), dissolved in 40mL ethylene glycol. Bi 2 WO 6 Precursors and nano TiO 2 Fiber cloth joins in the alcohol heat kettle, wherein Bi 2 WO 6 Precursor and Nano TiO 2 The mass ratio of the fiber cloth is 1200:1. After sealing the kettle, put it in an oven, and heat it with alcohol at a temperature of 160° C. for 16 hours to make Bi 2 WO 6 nanoparticles form nanosheets and further grow on TiO 2 On the fiber cloth, the Bi with hierarchical heterostructure 2 WO 6 / TiO 2 Fiber cloth.

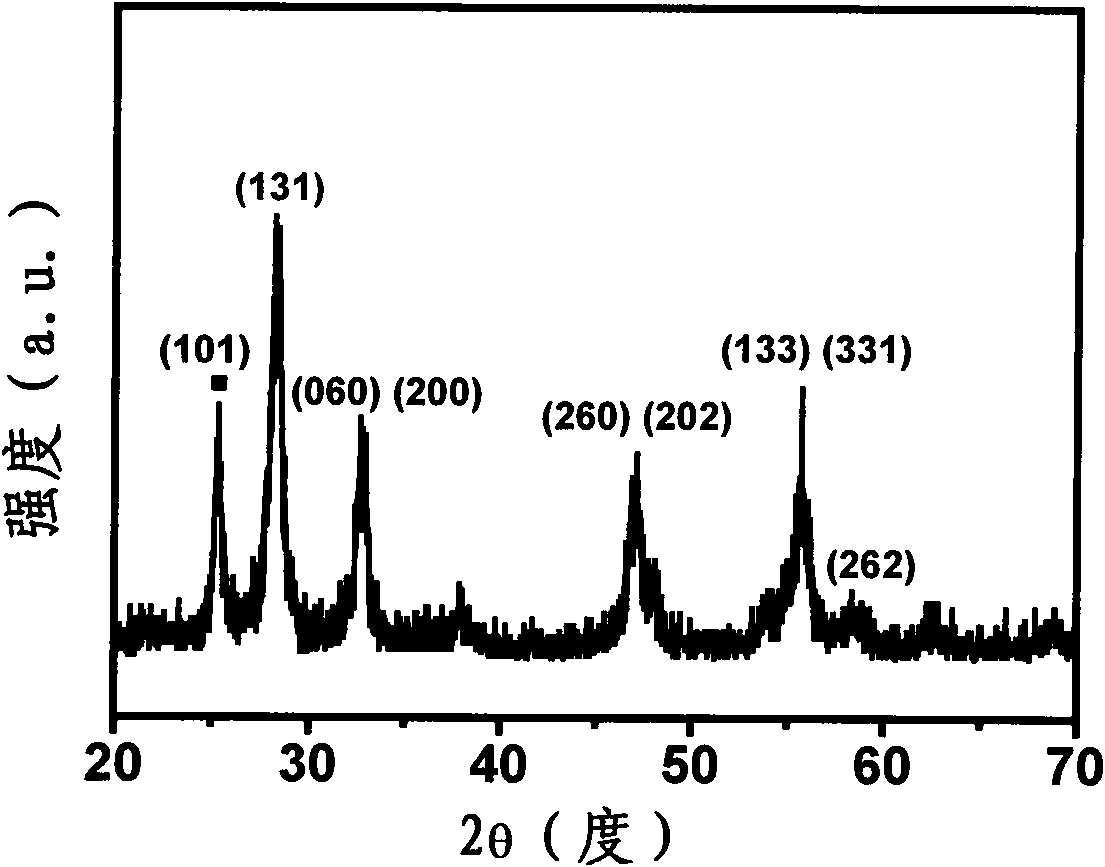

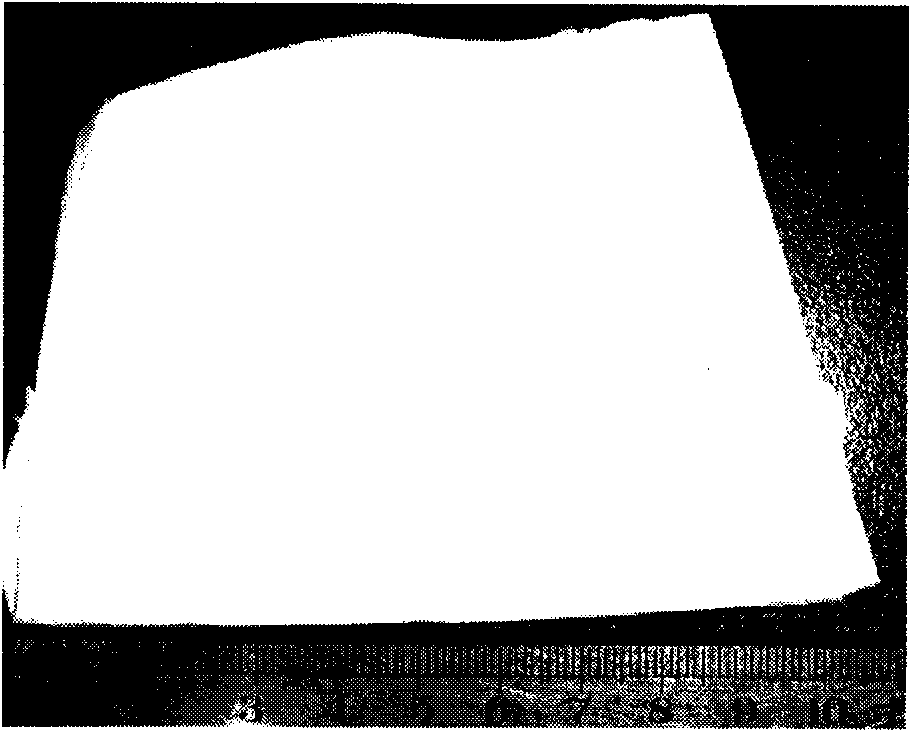

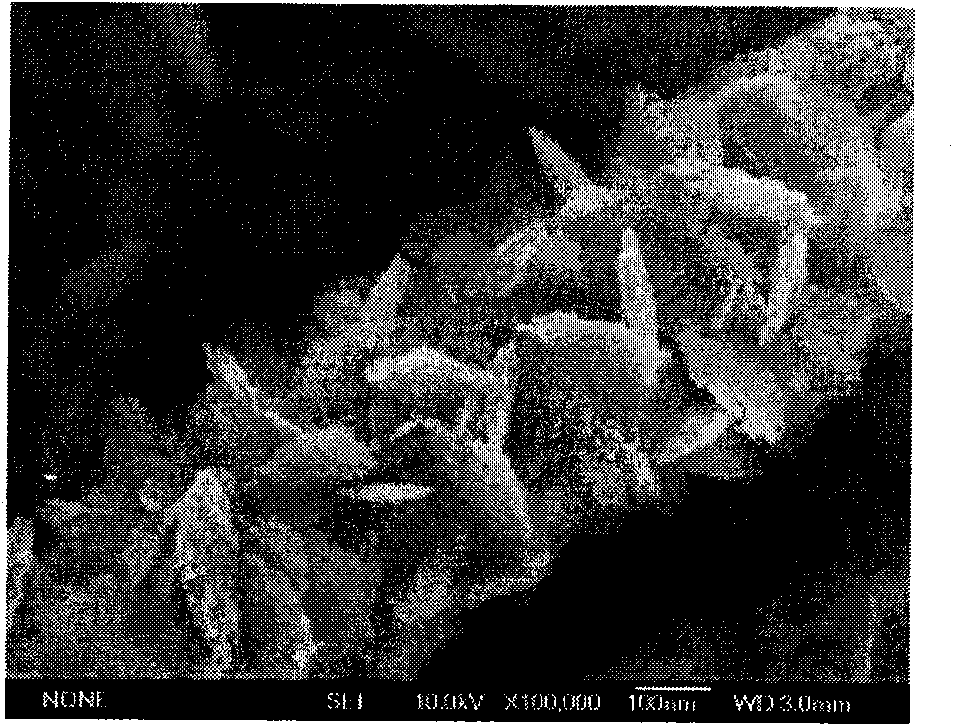

[0039] After XRD component analysis, Bi 2 WO 6 with TiO 2 Composite nanofiber cloth. According to electron microscope observation, the fiber cloth is made of Bi with a side length of 70nm and a thickness of 15nm pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com