Lithium ion battery cathode, preparation method thereof and lithium ion battery applying the same

A lithium-ion battery and negative electrode technology, which is applied in the field of carbon nanotube-based lithium-ion battery negative electrode and its preparation, can solve the problems of poor cycle performance, limited adsorption capacity, good cycle performance, etc., achieve excellent electrical conductivity, and improve stability. , the effect of increasing the amount of embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

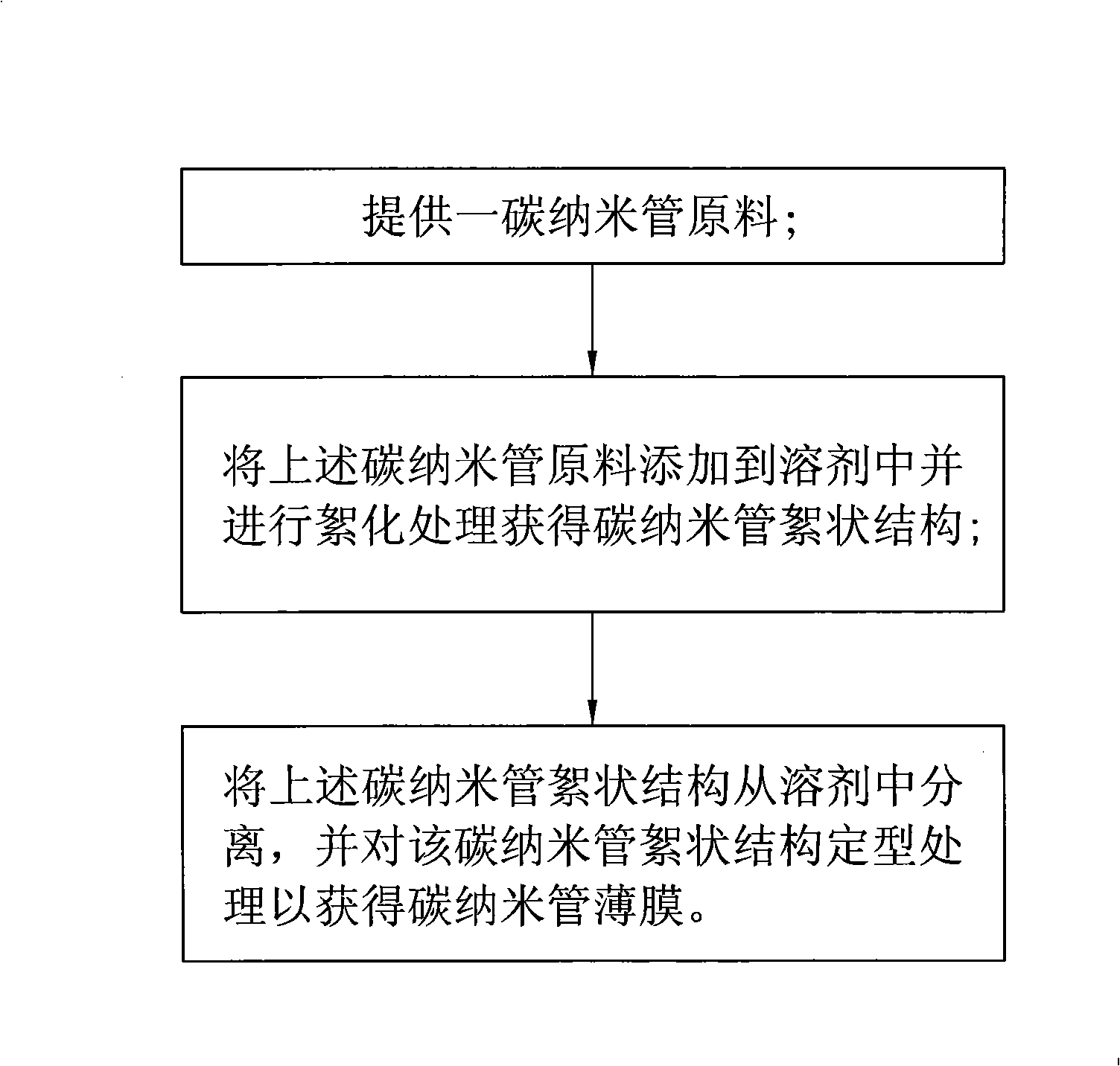

[0038] see figure 2 The embodiment of the technical solution further provides a method for preparing a negative electrode of a lithium-ion battery, which specifically includes the following steps:

[0039] Step 1, providing a carbon nanotube raw material. The obtaining of carbon nanotube raw material comprises the following steps:

[0040] First, a carbon nanotube array is provided.

[0041] In this embodiment, the preparation method of the carbon nanotube array adopts the chemical vapor deposition method, and the specific steps include: (a) providing a flat substrate, which can be a P-type or N-type silicon substrate, or a silicon substrate with an oxide layer formed on it. Silicon substrate, the present embodiment preferably adopts a 4-inch silicon substrate; (b) uniformly form a catalyst layer on the surface of the substrate, and the catalyst layer material can be selected from iron (Fe), cobalt (Co), nickel (Ni) or any of them One of the combined alloys; (c) annealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com