Preparation method of individually-self-supporting MIL-53 metal-organic framework membrane material

A metal-organic framework, MIL-53 technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of low cost, easy availability of raw materials and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

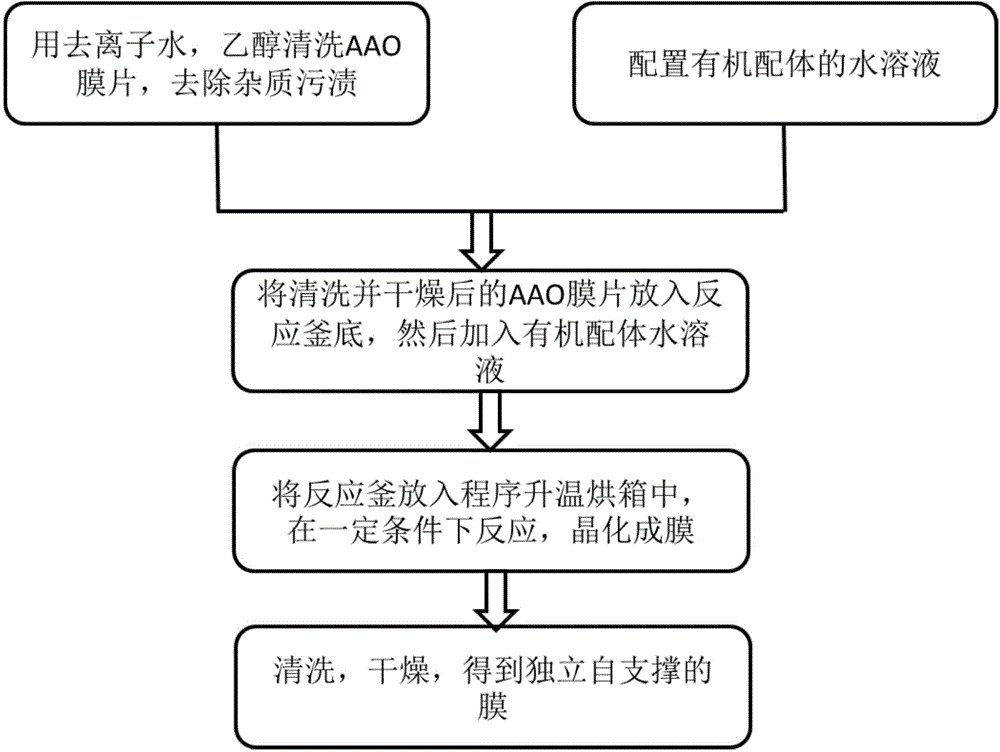

[0039] The steps to prepare a uniform and continuous independent self-supporting MIL-53 film by hydrothermal method are as follows:

[0040] The first step, precursor pretreatment: take a beaker, pour 25ml of deionized water, and immerse 15mg of AAO membrane (diameter 1.2cm, pore diameter 150-200nm, pore spacing 350-400nm, pore depth 50-70μm) Wash twice in deionized water, pour out the cleaning solution; then pour 25ml of absolute ethanol (mass percentage purity 97.0%) into the beaker, continue to wash twice and take it out; then put it into a petri dish, and dry it at a drying temperature of 60°C Dry treatment for 35 minutes; remove and clean the AAO membrane for use;

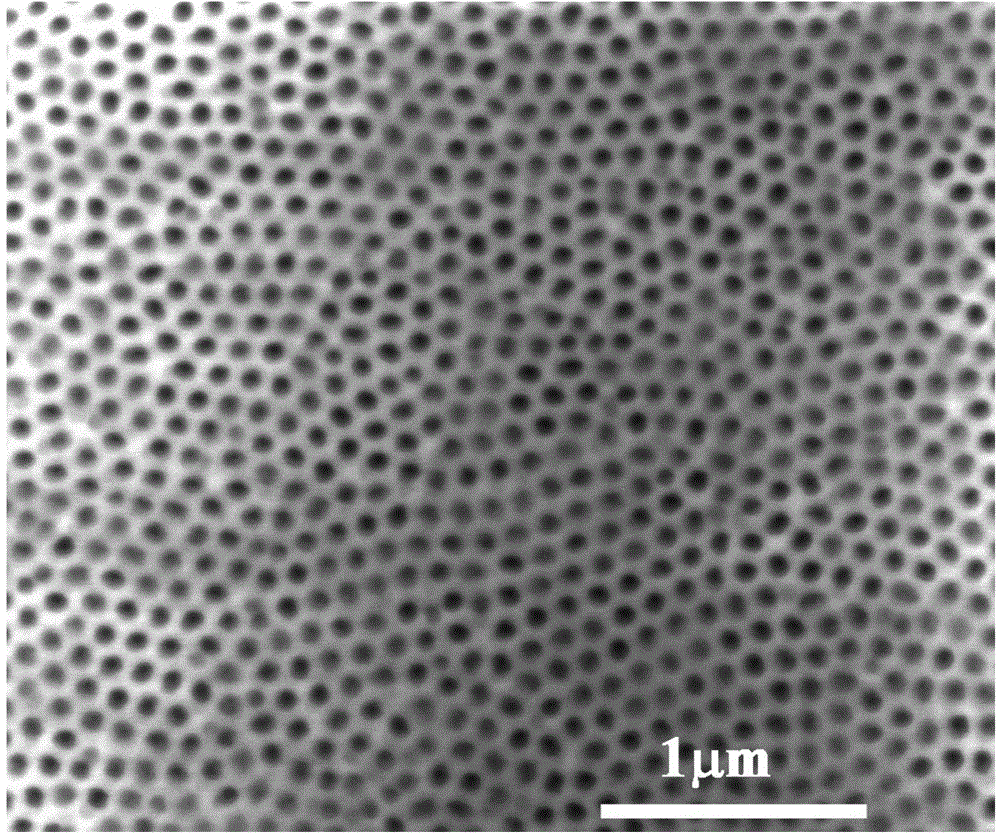

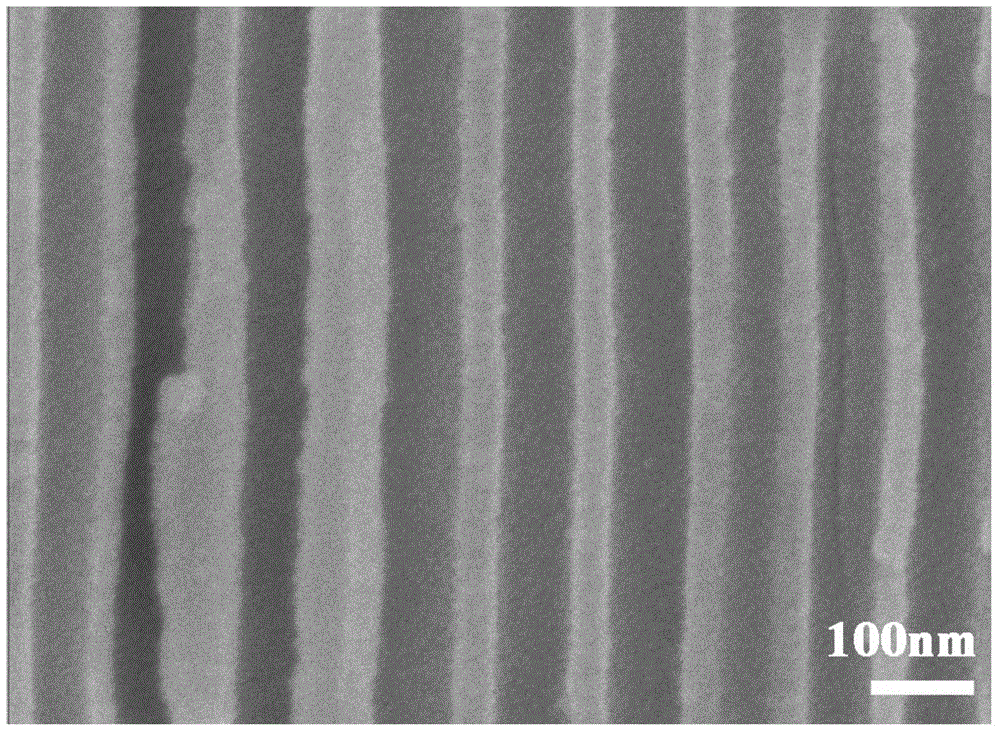

[0041] The anodized aluminum (AAO) diaphragm is selected from the double-pass AAO template produced by Shanghai Shangmu Technology Co., Ltd. Please refer to the SEM photo of the electron microscope scanning of the selected double-pass AAO template figure 2 and Figure 2A shown. figure 2 It is a high-power ...

Embodiment 2

[0049] The steps to prepare a uniform and continuous independent self-supporting MIL-53 film by hydrothermal method are as follows:

[0050] The first step, precursor pretreatment: take a beaker, pour 40ml of deionized water, and immerse 15mg of AAO membrane (diameter 2.5cm, pore diameter 150-200nm, pore spacing 350-400nm, pore depth 50-70μm) Wash twice in deionized water, pour out the cleaning solution, then pour 40ml of absolute ethanol (mass percentage purity 97.0%) into the beaker, continue to wash twice and take it out, then put it into a petri dish, and dry it at a drying temperature of 70°C Dry treatment for 50 minutes; remove and clean the AAO membrane for use;

[0051] The second step is to prepare the organic ligand solution: measure 15ml deionized and pour it into a beaker, weigh 100mg of analytically pure terephthalic acid, pour it into a beaker filled with deionized water, and then place the beaker under a magnetic force On the stirrer, after stirring at a consta...

Embodiment 3

[0056] The steps to prepare a uniform and continuous independent self-supporting MIL-53 film by hydrothermal method are as follows:

[0057] The first step, precursor pretreatment: take a beaker, pour 25ml of deionized water, and immerse 15mg of AAO membrane (diameter 1.2cm, pore diameter 150-200nm, pore spacing 350-400nm, pore depth 50-70μm) Wash twice in deionized water, pour out the cleaning solution; then pour 25ml of absolute ethanol (mass percentage purity 97.0%) into the beaker, continue to wash twice and take it out; then put it into a petri dish, and dry it at a drying temperature of 60°C Dry treatment for 35 minutes; remove and clean the AAO membrane for use;

[0058] The second step is to prepare an organic ligand solution: measure 25ml deionized and pour it into a beaker, weigh 100mg of analytically pure terephthalic acid, pour it into a beaker filled with deionized water, and then place the beaker under a magnetic force On the stirrer, after stirring at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com