Topological optimization design method of self-supporting structure in additive manufacturing

A self-supporting structure, topology optimization technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as poor practicability, and achieve the effects of good practicability, easy convergence, and less compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

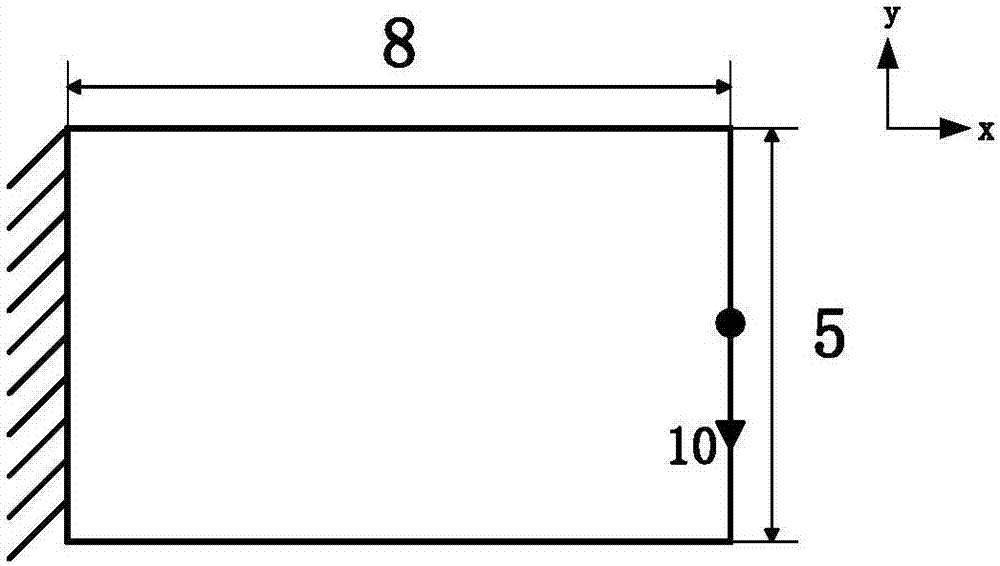

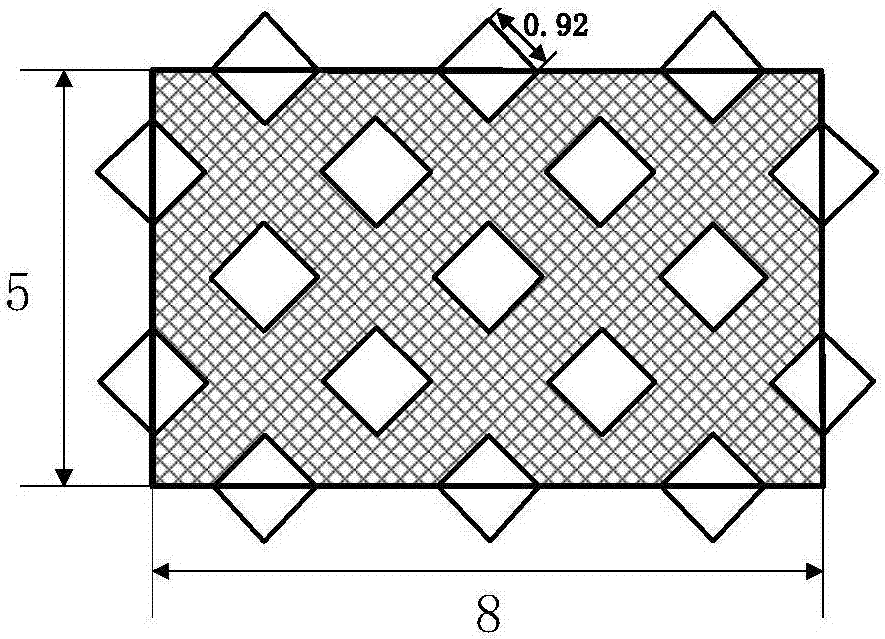

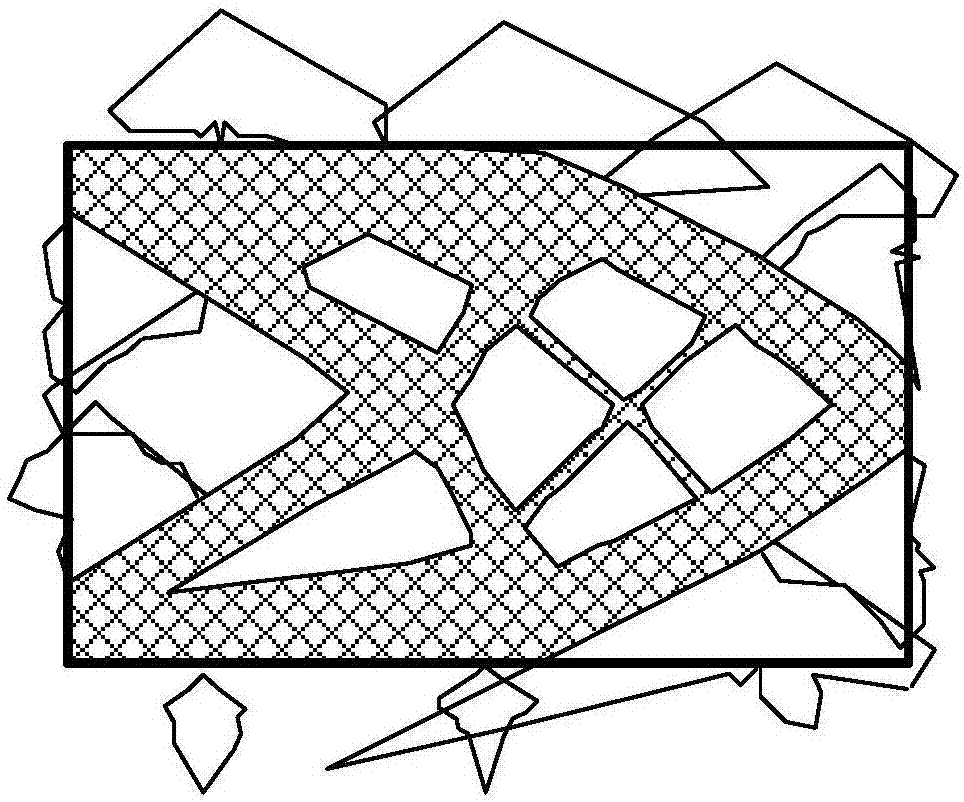

[0027] refer to Figure 1-3 . The topology optimization design method of the self-supporting structure in the additive manufacturing of the present invention takes the cantilever beam structure under a fixed load as an example to illustrate the present invention. The structure size of the cantilever beam is 8 in length and 5 in height, its Young's modulus is 1, and Poisson's ratio is 0.3. The material distribution in the cantilever beam is designed such that its compliance is minimal and the total material usage volume fraction is maximum 50%. Specific steps are as follows:

[0028] 1. Define the design variables. In this embodiment, a 24-sided hole is used, and the included angles between any adjacent vertices and the central point are required to be equal, and the included angle can be obtained to be 15°. The critical ratio of the distances from two adjacent vertices to the center point is solved in sequence. This critical ratio makes the angle between the side where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com