Preparation method of nanostructure

A nanostructure and carbon nanotube structure technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of small length, limited length of silicon nitride nanowires, affecting product size and uniformity, etc. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

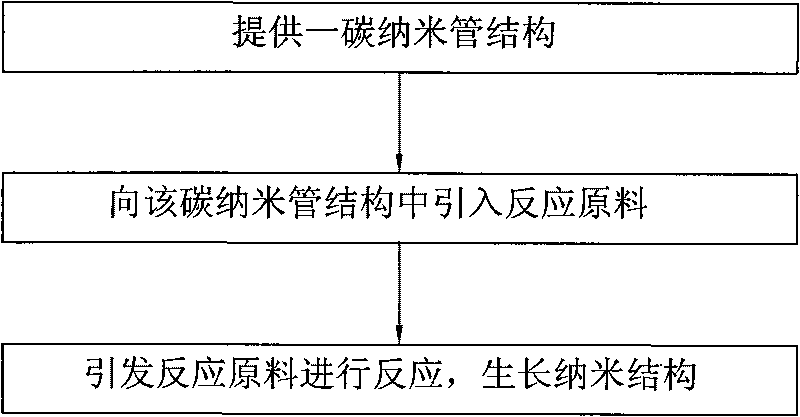

[0030] See figure 1 , The present invention provides a method for preparing nanostructures, which includes the following steps:

[0031] Step 1: Provide a carbon nanotube structure.

[0032] The carbon nanotube structure is a self-supporting structure. The so-called "self-supporting structure" means that the carbon nanotube structure can maintain its own specific shape without being supported by a support. The carbon nanotube structure includes at least one carbon nanotube film, at least one carbon nanotube-like structure or a combination thereof. When the carbon nanotube structure includes a plurality of carbon nanotube films, the carbon nanotube films may be coplanar or stacked. When the carbon nanotube structure only includes a carbon nanotube-like structure, the carbon nanotube-like structure can be folded or wound into a layered carbon nanotube structure. When the carbon nanotube structure includes a plurality of carbon nanotube wire-like structures, the plurality of carbon...

Embodiment 1

[0071] See Picture 9 , The first embodiment of the present invention provides a method for preparing the titanium dioxide nanostructure 104, which specifically includes the following steps:

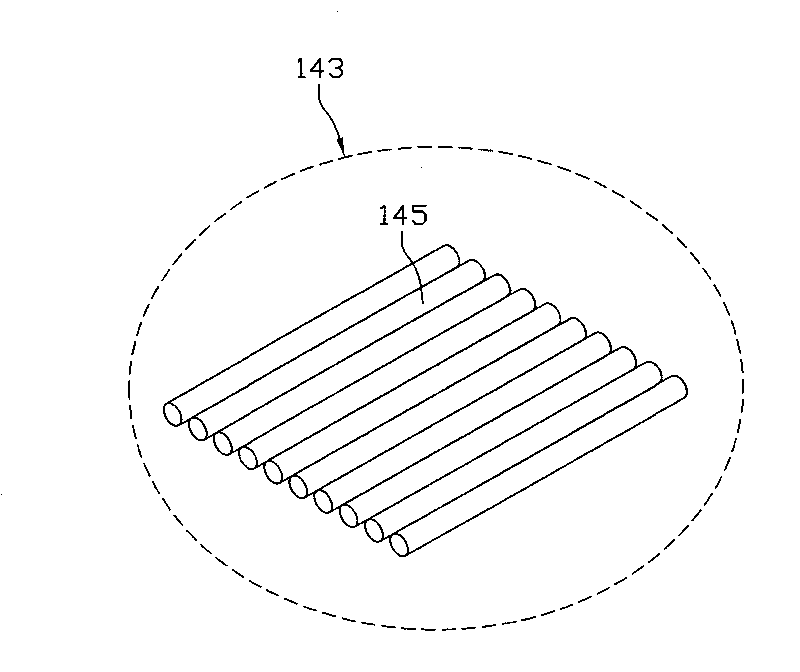

[0072] Step 1: Provide a two-dimensional carbon nanotube structure 100, which includes two drawn carbon nanotube films stacked in the same direction.

[0073] In this embodiment, two drawn carbon nanotube films are laminated and laid on a metal ring to obtain a carbon nanotube structure 100, and the carbon nanotubes in the two drawn carbon nanotube films are arranged in the same direction.

[0074] Step two, introducing titanium reaction raw material 102 and oxygen into the carbon nanotube structure 100.

[0075] In this embodiment, a 100-nanometer-thick titanium layer is deposited on the surface of the carbon nanotube structure 100 by magnetron sputtering. See Picture 10 , The titanium particles are uniformly distributed on the surface of the carbon nanotubes in the drawn carbon nanotube film....

Embodiment 2

[0082] See Figure 14 The second embodiment of the present invention provides a method for preparing the titanium dioxide nanostructure 204. The preparation method of the titanium dioxide nanostructure 204 is basically the same as the preparation method of the titanium dioxide nanostructure in the first embodiment of the present invention. The difference is that: in this embodiment, two carbon nanotube stretched films are stacked and vertically cross-laid as a template Growth of titanium dioxide nanostructures 204.

[0083] This embodiment specifically includes the following steps:

[0084] Step 1: Provide a two-dimensional carbon nanotube structure 200, the carbon nanotube structure 200 includes two stacked and vertically cross-laid drawn carbon nanotube films.

[0085] In this embodiment, two drawn carbon nanotube films are stacked and laid vertically and crosswise on a metal ring to obtain a carbon nanotube structure 200. The arrangement direction of the carbon nanotubes in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com