Graphene-based flexible composite electrode material and preparation method and application thereof

An alkenyl-based flexible and composite electrode technology, applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc. Chemical properties, high film strength, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Correspondingly, an embodiment of the present invention provides a method for preparing a graphene-based flexible composite electrode material, comprising the following steps:

[0027] S01. Provide graphene and two-dimensional active materials respectively;

[0028] S02. dispersing the graphene and the two-dimensional active material in a solvent to form a mixed dispersion;

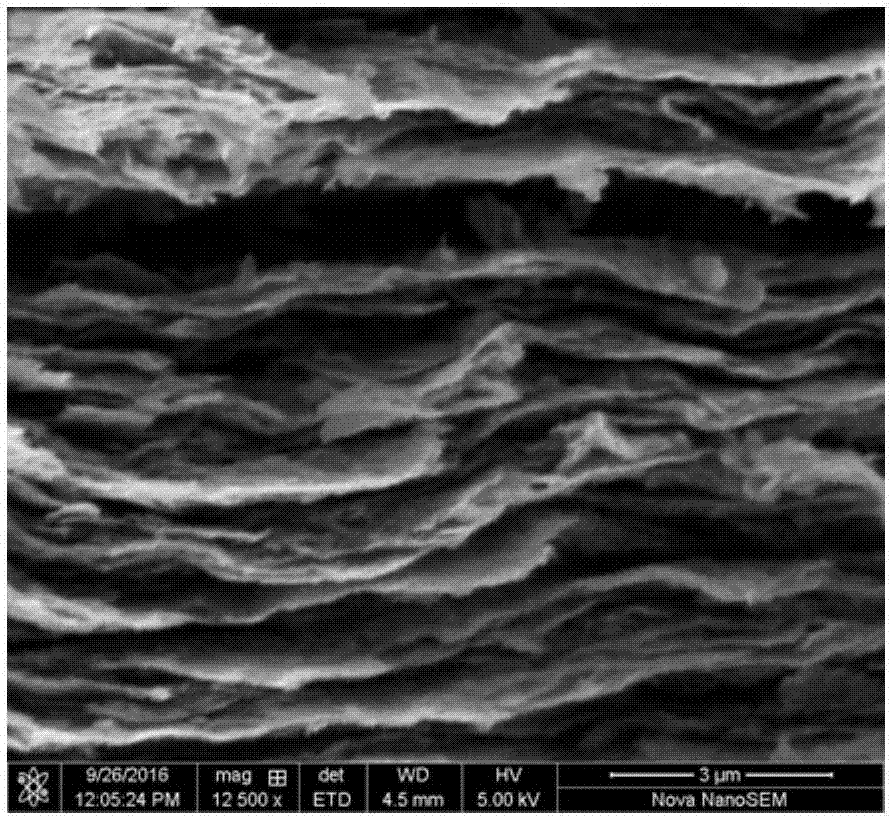

[0029] S03. The mixed dispersion liquid is subjected to layer-by-layer assembly processing to obtain a graphene-based flexible composite electrode material; or the mixed dispersion liquid is subjected to layer-by-layer assembly processing and then heat-treated to obtain a graphene-based flexible composite electrode material.

[0030] In the above step S01, the graphene is two-dimensional graphene, and the graphene is prepared by electrochemical exfoliation, or the preparation method of the graphene is: preparing graphene oxide by chemical oxidation exfoliation, for the graphite oxide Graphene is o...

Embodiment 1

[0049] A preparation method of a graphene-based flexible composite electrode material, comprising the following steps:

[0050] S11. Provide graphene and two-dimensional active materials, respectively.

[0051] Electrochemical exfoliation of graphite rods to prepare graphene: use high-purity graphite rods as working electrodes, platinum sheets as counter electrodes, 0.1MNa 2 SO 4 The aqueous solution is an electrolyte, and the working voltage is 10V. After the peeling is complete, the few-layer graphene is collected by washing, ultrasonication, and centrifugation; and the graphene is dispersed in the organic solvent DMF with a solubility of 0.5 mg / mL.

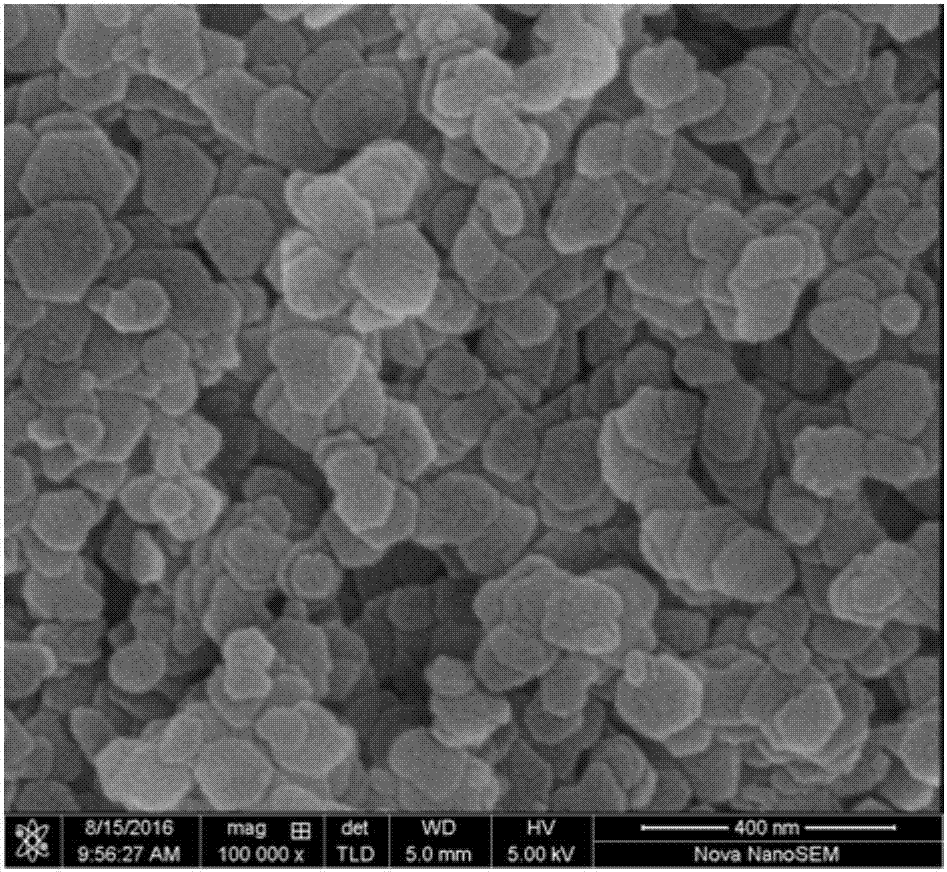

[0052] Preparation of nickel hydroxide nanosheets by chemical method: dissolve 1mL ammonia water (38%) in 50mL water, gradually add dropwise to 50mL0.04M NiCl 2 ·6H 2 O aqueous solution, stirred at 60°C for 12h, collected and dried; and dispersed nickel hydroxide nanosheets in the organic solvent DMF, with a solubility of 0....

Embodiment 2

[0059] A preparation method of graphene-based flexible composite electrode material, on the basis of preparing nickel hydroxide / graphene composite electrode material in embodiment 1, the nickel hydroxide / graphene composite electrode material is carried out in-situ heat treatment, in Ar atmosphere The heating rate was 5°C / min, the temperature was kept at 400°C for 2h, and the nickel oxide / graphene composite electrode material was obtained by natural cooling. The electrical conductivity of the graphene film, nickel oxide, and the prepared flexible composite electrode material of Example 2 are shown in Table 2.

[0060] Table 2

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com