Preparation method of self-support lithium ion battery cathode material

A technology for lithium-ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low initial Coulomb efficiency, poor thermodynamic stability, and volume expansion during charge and discharge, and achieve excellent electrochemical performance and mechanical stability. The effect of high performance and high magnification characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

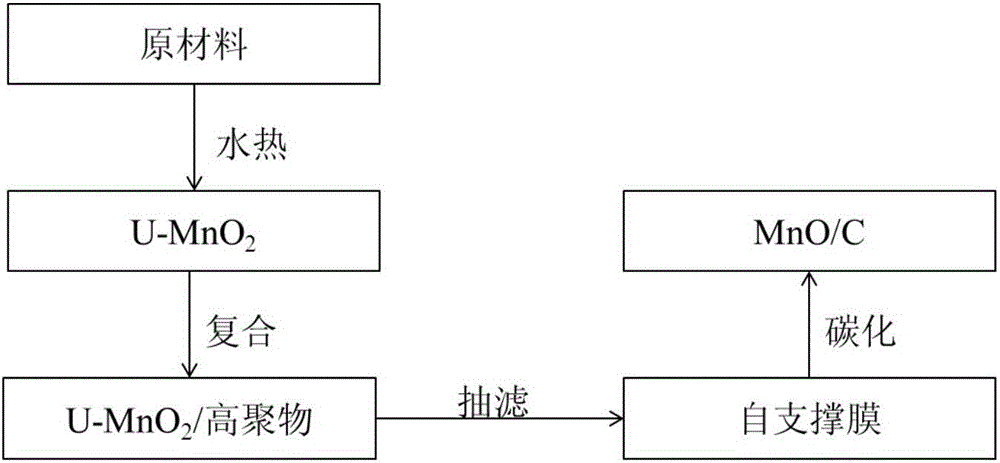

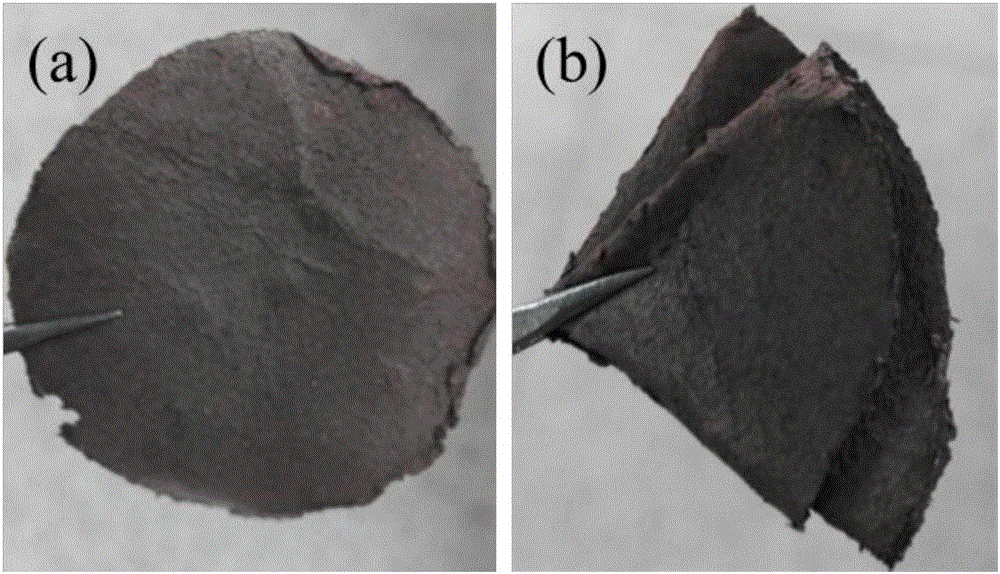

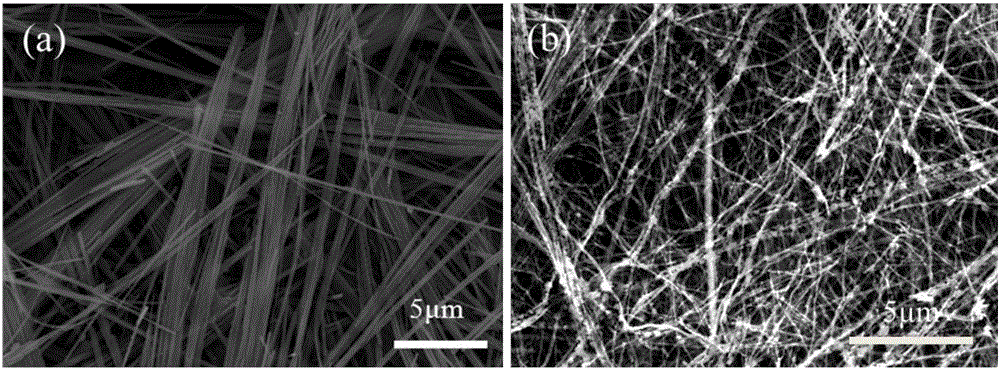

[0028] 1) Weigh 4mmol of manganese sulfate, 6mmol of potassium chlorate, 7mmol of potassium acetate and 4mL of acetic acid into 60mL of deionized water. After fully stirring and dissolving, transfer the solution into a hydrothermal kettle with a capacity of 100mL, and put the hydrothermal kettle into a drying oven heated to 160°C for 12 hours, and cooled naturally to room temperature after the completion of the hydrothermal reaction to obtain U-MnO 2 , washed three times with deionized water and absolute ethanol, and the obtained U-MnO 2 The self-supporting film was dried at 90°C for 24 hours, and the picture of the self-supporting film is attached figure 1 , where (a) is a self-supporting film with a diameter of 50 mm, and (b) is a picture of the self-supporting film after being folded twice, which shows that it has high mechanical strength and toughness. U-MnO 2 The scanning electron microscope picture is attached figure 2 as shown in (a);

[0029] 2) Weigh 200mg of U-M...

Embodiment 2

[0032] 1) Weigh 20mmol of manganese sulfate and 20mmol of ammonium persulfate into 80mL of deionized water, stir evenly, then add 50mmol of ammonium sulfate, stir for 30min, transfer the solution into a hydrothermal kettle with a capacity of 100mL, put the hydrothermal kettle into Put it in a drying oven and heat it to 180°C for 12 hours, and then cool it down to room temperature naturally after the hydrothermal reaction is completed, to obtain U-MnO 2 . Use ultrapure water and absolute ethanol to wash 3 times respectively, and the U-MnO obtained by suction filtration 2 Dry the self-supporting film at 90°C for 24h;

[0033] 2) Weigh 200mg of U-MnO prepared in step 1) 2 , add it to 20mL 0.1M HCl, stir evenly, then add 60μL pyrrole, stir at room temperature for 30min and let it stand for 4h to get U-MnO 2 Polypyrrole was washed three times with ultrapure water and absolute ethanol, filtered to form a film, and dried in vacuum at 60°C for 12 hours;

[0034] 3) U-MnO prepared ...

Embodiment 3

[0036] 1) Weigh 6mmol of manganese nitrate, 8mmol of potassium chlorate, 8mmol of potassium acetate and 4mL of acetic acid and add them into 90mL of ultrapure water. Heat it in the box to 160°C for 16 hours, cool it down to room temperature naturally after the hydrothermal reaction, and get U-MnO 2 , washed three times with ultrapure water and absolute ethanol, and the U-MnO obtained by suction filtration 2 The self-supporting film was air-dried at 90°C for 48 hours;

[0037] 2) Weigh 200mg of U-MnO prepared in step 1) 2 , which was added to 40mL 0.1M HNO 3 , stirred evenly, then added 80 μL of thiophene, stirred at room temperature for 60 minutes, and left to react for 4 hours to obtain U-MnO 2 Polythiophene, washed 3 times with ultrapure water and absolute ethanol, filtered to form a film and dried in vacuum at 60°C for 24 hours;

[0038] 3) U-MnO prepared in step 2) 2 Polythiophene, placed in a tube furnace, at N 2 (120sccm) atmosphere, heat up to 700°C at a heating rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com