Bi2WO6 nano-fiber cloth and preparation method and application thereof

A nanofiber and fiber technology, which is applied in the field of Bi2WO6 nanofiber cloth, preparation and application, can solve the problems of reduced catalytic performance and reduced surface area of catalyst, and achieve the effects of short cycle, convenient recycling and reuse, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

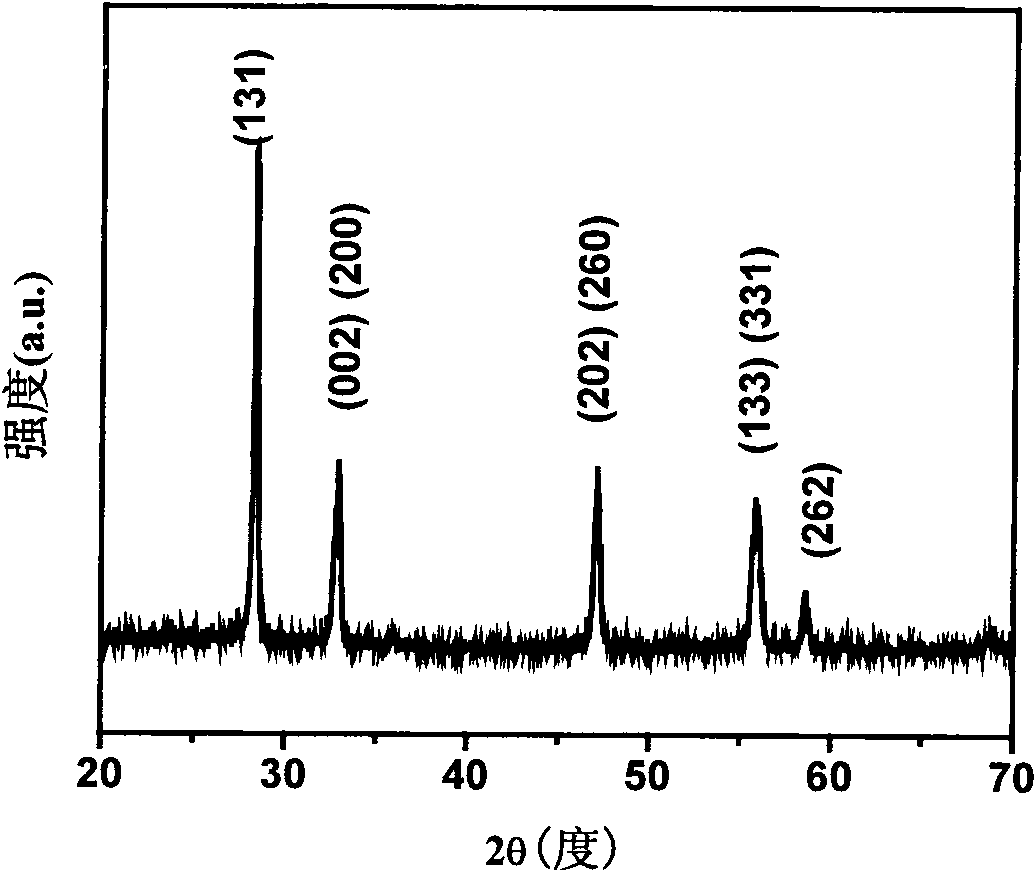

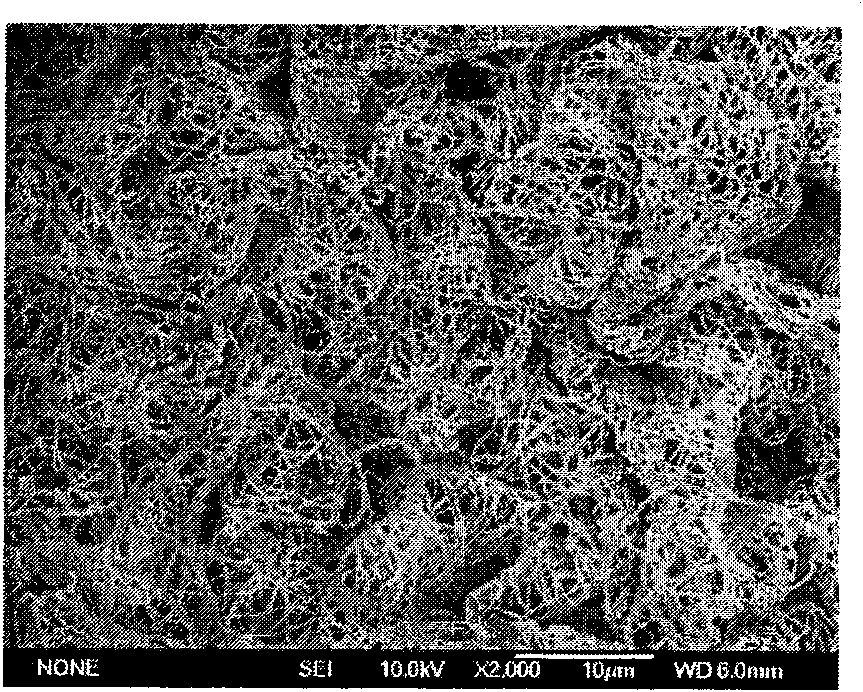

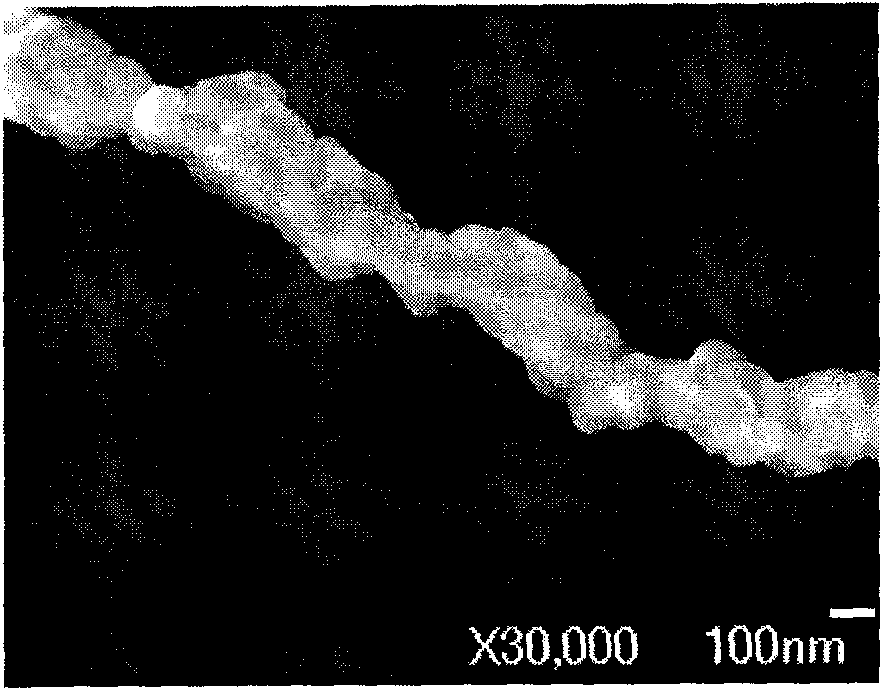

[0025] Bi 2 WO 6 Using Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O (analytical pure) is synthesized as a raw material, and according to the stoichiometric ratio, weigh 0.97g Bi(NO 3 ) 3 ·5H 2 O (analytical grade) was dissolved in 20 mL of ethanol, and then 0.329 g of Na 2 WO 4 2H 2 O (analytically pure), 1g of PVA was stirred to form a white suspension precursor. Then put the precursor solution into the syringe for electrospinning. After comparative experiments, the working distance is 10cm and the working voltage is 20KV. After the reaction, the obtained nanofiber cloth was sintered at 500°C. Such as figure 1 , according to XRD composition analysis and Debye Scherer formula calculation, the nanofiber Bi composed of about 100nm particles was obtained 2 WO 6 . Figure 2 is a typical scanning electron micrograph of the spinning sample. It can be seen from the figure that the diameter of the self-supporting nanofiber is about 150nm, which is actually made of nano-Bi ...

Embodiment 2

[0029] Bi 2 WO 6 Using bismuth citrate and Na 2 WO 4 2H 2 O (analytical pure) is synthesized as a raw material, according to the stoichiometric ratio, weigh 0.796g bismuth citrate (analytical pure) and dissolve it in 20mL of ethanol, then add 0.329gNa 2 WO 4 2H 2 O (analytically pure), 0.5g PEO was stirred to form a white suspension precursor. Then put the precursor solution into the syringe for electrospinning. After comparative experiments, the working distance was selected as 20cm, and the working voltage was 25KV. After the reaction, the obtained nanofiber cloth was sintered at 400°C. The product was determined to be Bi by XRD component analysis 2 WO 6 , the particle size is about 200nm observed by electron microscope, and visible light with a wavelength > 420nm degrades acetaldehyde to produce CO 2 Experimental result is slightly lower than embodiment 1, CO 2 The concentration is 117ppm.

Embodiment 3

[0031] Bi 2 WO 6 Using bismuth oxalate and H 40 N 10 o 41 W 12 ·xH 2 O (analytical pure) is synthesized as a raw material, according to the stoichiometric ratio, weigh 1.617g bismuth oxalate (analytical pure) and dissolve it in 20mL ethanol, then add 0.329g Na 2 WO 4 2H 2 O (analytically pure), 1g of PVP was stirred to form a white suspension precursor. Then put the precursor solution into the syringe for electrospinning. After comparative experiments, the working distance is 25cm and the working voltage is 10KV. After the reaction, the obtained nanofiber cloth was sintered at 550°C. The product was determined to be Bi by XRD component analysis 2 WO 6 , the particle size is about 300nm observed by electron microscope, and visible light with a wavelength > 420nm degrades acetaldehyde to produce CO 2 Experimental result is lower than embodiment 1, CO 2 The concentration is 95ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com