Full-biodegrade composite material taking oriented poly butylene succinate as nucleating agent and preparation method of full-biodegrade composite material

A technology of polybutylene succinate and polybutylene succinate, which is applied in the field of fully biodegradable composite materials and its preparation, can solve the problems of toughness, elongation at break, strength defects, biodegradation rate, The problem of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

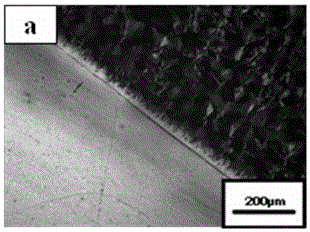

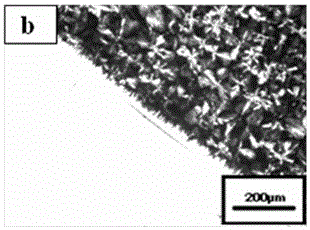

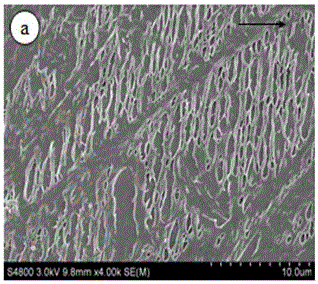

Image

Examples

Embodiment 1

[0022] Take polybutylene succinate as the preparation method of the polybutylene adipate composite material of nucleating agent, it is characterized in that, comprises the following steps:

[0023] 1) Dry polybutylene adipate under vacuum at 40°C for 3 hours, and dry polybutylene succinate under vacuum at 100°C for 3 hours;

[0024] 2) Mechanically blend 30% polybutylene adipate and 70% polybutylene succinate, put the mixed powder into a screw extruder, blend and extrude to obtain a composite material , the temperature of the screw extruder is 90 to 200°C;

[0025] 3) The composite material of polybutylene adipate and polybutylene succinate was rolled and pressed on one side at a processing temperature of 115°C; the pressure of the composite material was 150 Pa, and it was subjected to a single The pressure time is 150s;

[0026] 4) Take out the formed composite material and heat treat it at 40°C.

[0027] The tensile strength of the composite material was tested with a ten...

Embodiment 2

[0029] The preparation method of the fully biodegradable composite material using orientation polybutylene succinate as a nucleating agent is characterized in that it comprises the following steps:

[0030] 1) Dry the polybutylene adipate under vacuum at 25°C for 8 hours, and dry the oriented polybutylene succinate under vacuum at 60°C for 8 hours;

[0031] 2) Mechanically blend 50% polybutylene adipate and 50% polybutylene succinate, put the mixed powder into a screw extruder, blend and extrude to obtain a composite material , the temperature of the screw extruder is 90 to 200°C;

[0032] 3) Perform single-side rolling and plate pressing on the composite material of polybutylene adipate and polybutylene succinate at a processing temperature of 116°C; the pressure of the composite material is 400Pa, subjected to a single constant The pressure time is 170s;

[0033] 4) Take out the formed composite material and heat treat it at 30°C.

[0034] The tensile strength of the comp...

Embodiment 3

[0036] The preparation method of the fully biodegradable composite material using orientation polybutylene succinate as a nucleating agent is characterized in that it comprises the following steps:

[0037] 1) Dry the polybutylene adipate under vacuum at 25°C for 8 hours, and dry the oriented polybutylene succinate under vacuum at 60°C for 8 hours;

[0038] 2) Mechanically blend 70% polybutylene adipate and 30% polybutylene succinate, put the mixed powder into a screw extruder, blend and extrude to obtain a composite material , the temperature of the screw extruder is 90 to 200°C;

[0039] 3) The polybutylene adipate and polybutylene succinate composite material is rolled and pressed on one side at 118°C; the pressure of the composite material is 600Pa, and the time for a single constant pressure is 200s;

[0040] 4) Take out the formed composite material and heat treat it at 0°C.

[0041] The tensile strength of the composite was tested with a tensile machine; its thermody...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com