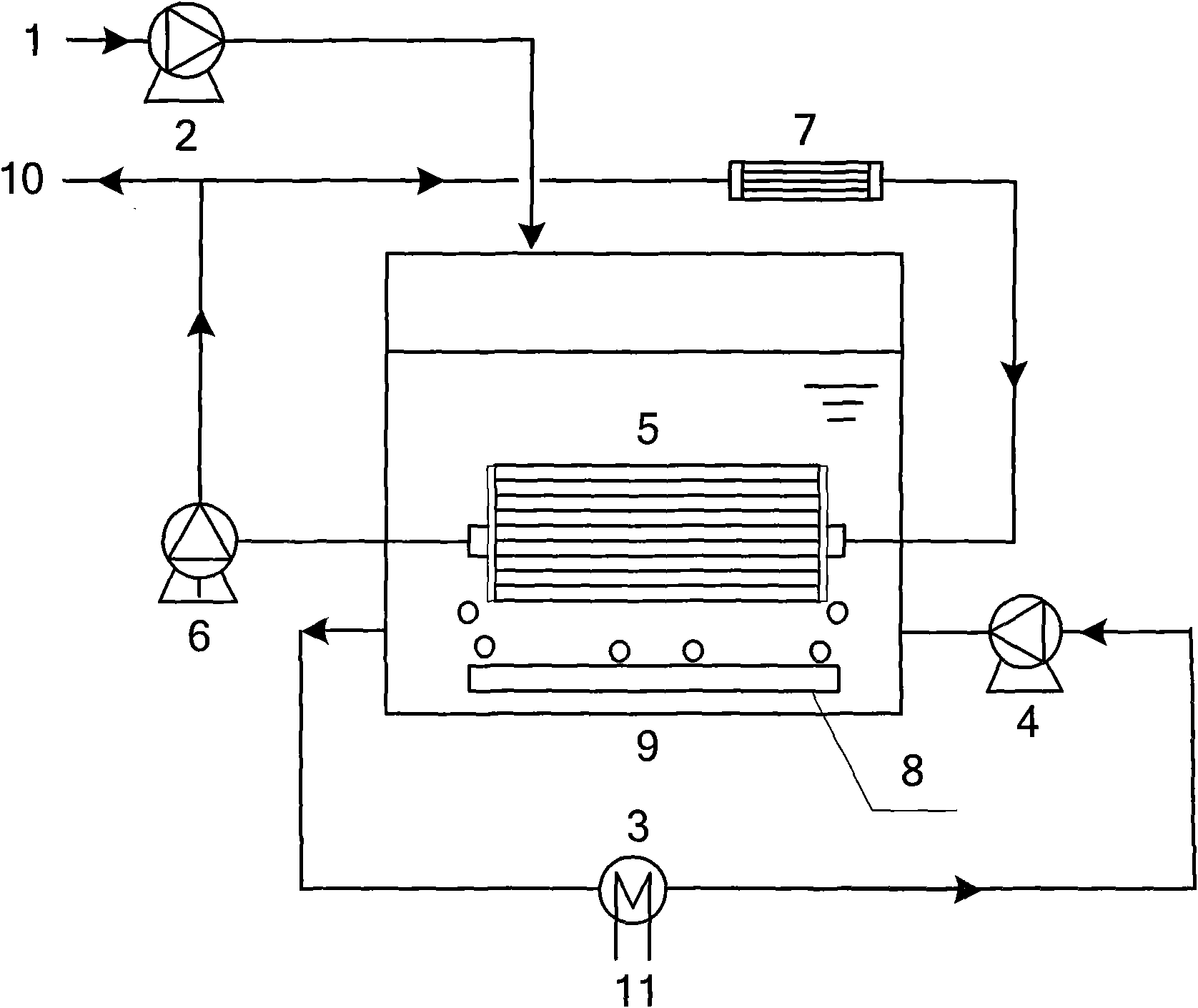

Membrane distillation bioreactor device and method

A bioreactor and membrane distillation technology, applied in the field of membrane distillation, can solve the problems of large floor space and poor color removal effect, and achieve the effects of small floor space, improved activity and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Small test of food processing wastewater treatment and reuse project, the treatment capacity is 10m 3 / d, raw water COD cr 200-500mg / L, BOD 100-200mg / L, SS 150-200mg / L. The flow rate of the condensate is 0.42-0.46m / s, the boiling water temperature is 50°C, 60°C, and 70°C respectively, the cooling water temperature is 32-35°C, the cooling water is reverse osmosis deionized water, and the conductivity is 18.8-21.2μs / cm . The pilot test results show that the membrane flux reaches 13kg / m under all operating conditions 2 More than h, effluent COD cr less than 0.5mg / L, the conductivity of stable product water is maintained between 25.1-26.3μs / cm, compared with the conductivity value of reverse osmosis pure water (18.8-21.2μs / cm), it can be concluded that the membrane module has no obvious permeability Leakage phenomenon, the effect is good.

Embodiment 2

[0031] Example 2: domestic sewage treatment and reuse project, the treatment capacity is 8m 3 / d, raw water COD cr 500-1000mg / L, BOD 150-400mg / L, SS 200-450mg / L. The condensate flow rate is 0.44-0.47m / s, the wastewater temperature is 50°C, 60°C, and 70°C respectively, the cooling water temperature is 32-35°C, the cooling water is reverse osmosis deionized water, and the conductivity is 18.8-21.2μs / cm . The pilot test results show that the membrane flux reaches 13kg / m under all operating conditions 2 More than h, effluent COD cr less than 0.5mg / L, the conductivity of stable product water is maintained between 25.1-26.3μs / cm, compared with the conductivity value of reverse osmosis pure water (18.8-21.2μs / cm), it can be concluded that the membrane module has no obvious permeability Leakage phenomenon, the effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com