Soil and underground water in-situ synergistic repair method

A technology of collaborative restoration and groundwater, applied in the restoration of polluted soil, etc., can solve problems such as the inability to provide living conditions for microorganisms, the inability of microorganisms to degrade pollutants, and the secondary pollution of chemical reagents. , the effect of eliminating pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] (3) the preparation method of described petroleum degrading bacterium agent can comprise the following steps:

[0029] Step 1, using an extractant to extract petroleum pollutants from polluted soil and groundwater, and then evaporating the extractant to obtain petroleum pollutants.

[0030] Step 2, NaCl, NH 4 Cl, MgSO 4 , KCl, FeSO 4 ·7H 2 O, CaCl 2 Added to the petroleum pollutants and diluted with distilled water to prepare inorganic salt culture medium with a pH value of 7.0-7.5. Among them, every 1000ml inorganic salt medium uses 10g NaCl, 0.5g NH 4 Cl, 0.5g MgSO 4 , 0.1g KCl, 0.02g FeSO 4 ·7H 2 O, 0.1g CaCl 2and 1ml of petroleum contamination from step 1.

[0031] Step 3. According to the ratio of using 200mL of the inorganic salt medium for every 15g of contaminated soil, add the contaminated soil to the inorganic salt medium, and acclimatize it in a constant temperature oscillator with a temperature of 30°C and a rotation speed of 180r / min Cultivate fo...

Embodiment 1

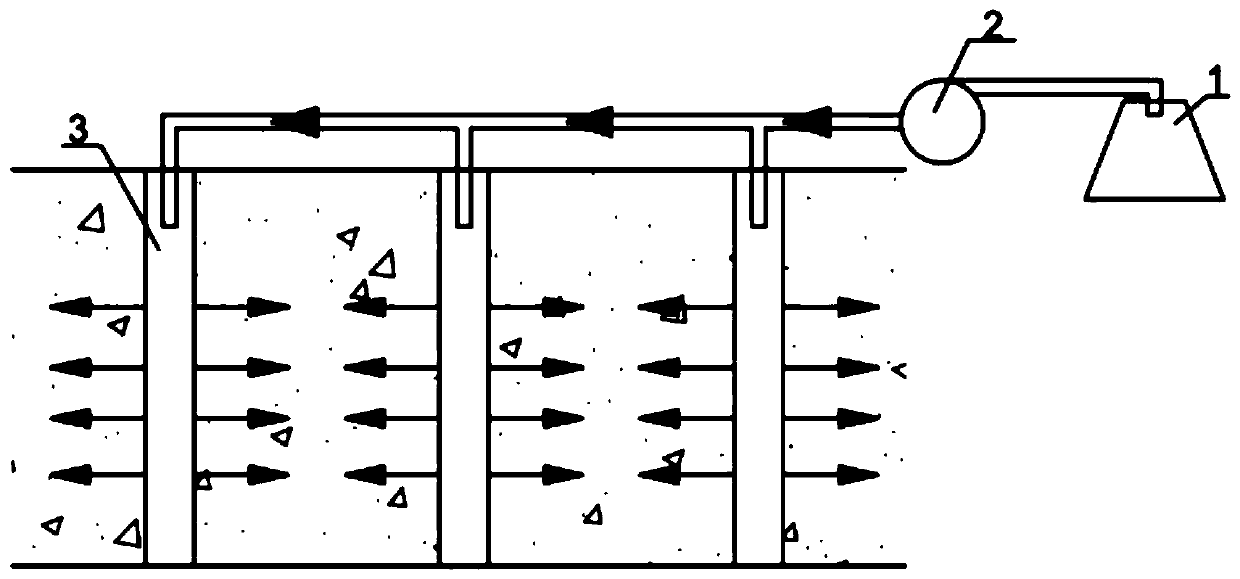

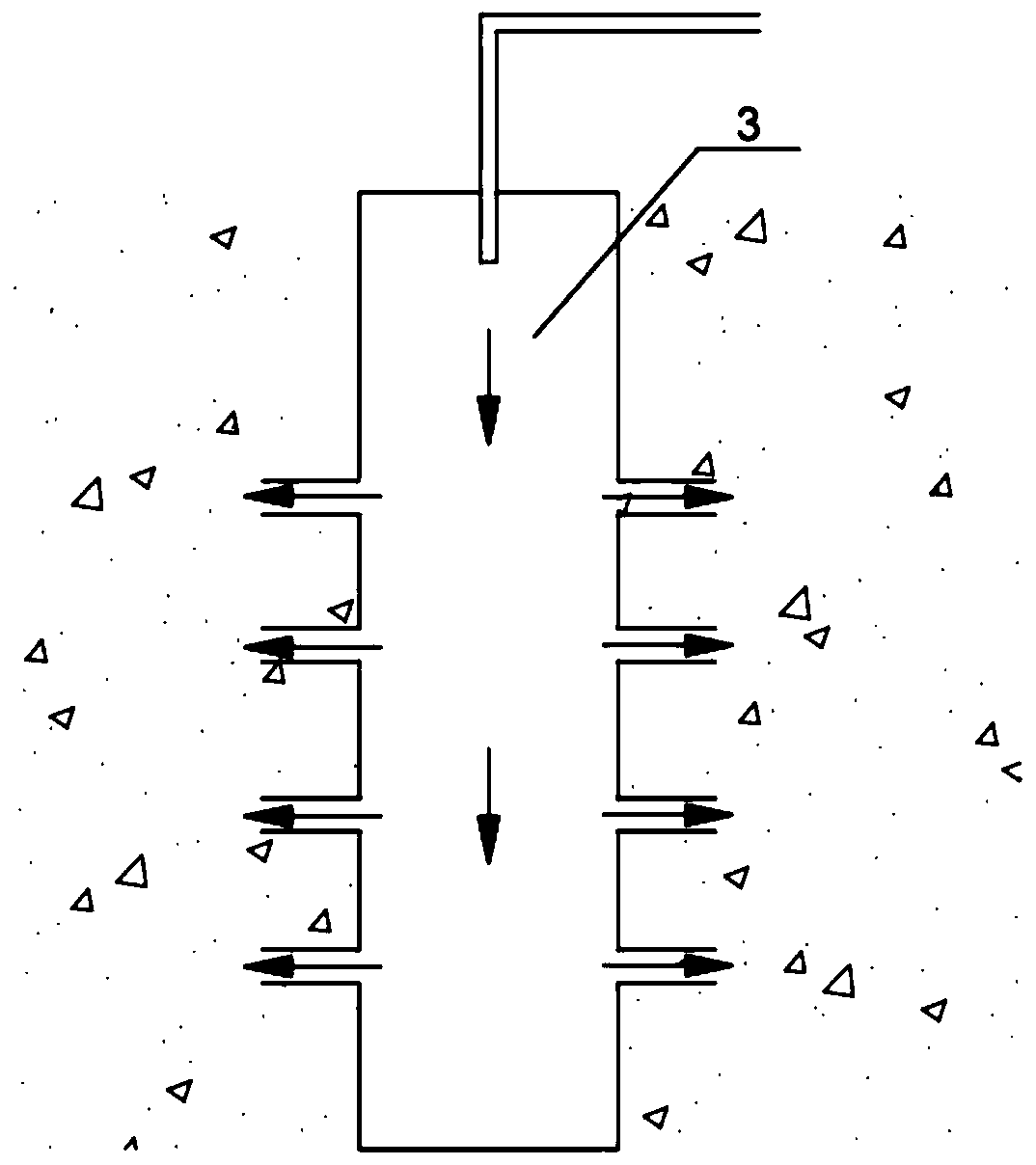

[0041] An in-situ collaborative restoration method for soil and groundwater, comprising: adding carbon elements, nitrogen elements, phosphorus elements, and oil-degrading bacterial agents with a concentration of 5,000 to 10,000 mg / L accounting for 0.6% of the total volume of the reinjection water to the reinjection water, and the carbon element , The weight ratio of nitrogen and phosphorus is C:N:P=100:5:1, and the reinjection water is aerated, and the aeration rate is kept at 1.8mg / L, thereby forming the final reinjection water; liquid injection pump 2 The final reinjection water is drawn from the bioaugmentation regulating pool 1, and reinjected into the formation through the reinjection well 3, so that the soil and groundwater can be restored in situ.

[0042] Specifically, the preparation method of the petroleum degrading bacterial agent may comprise the following steps:

[0043] Step A1, using an extractant to extract petroleum pollutants from polluted soil and groundwate...

Embodiment 2

[0049] An in-situ collaborative restoration method for soil and groundwater, comprising: adding carbon elements, nitrogen elements, phosphorus elements, and oil-degrading bacterial agents with a concentration of 5,000 to 10,000 mg / L accounting for 1% of the total volume of the reinjection water to the reinjection water, and the carbon element , the weight ratio of nitrogen and phosphorus is C:N:P=100:5:1, and the reinjection water is aerated, and the aeration rate is maintained at 2mg / L, thereby forming the final reinjection water; the injection pump 2 starts from The final reinjection water is extracted from the bioaugmentation regulating pool 1 and reinjected into the stratum through the reinjection well 3, so that the soil and groundwater can be restored synergistically in situ.

[0050] Specifically, the preparation method of the petroleum degrading bacterial agent may comprise the following steps:

[0051] Step B1, using an extractant to extract petroleum pollutants from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com