Method for grafting redox mediator on surface of inorganic filler and application

An inorganic filler and mediator technology, which is applied in the field of redox mediator grafting on the surface of inorganic fillers, can solve the problems of porous structure bacterial group blockage, low final yield, long reaction steps, etc., and achieve increased biodegradation rate, The effect of simple reaction process and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

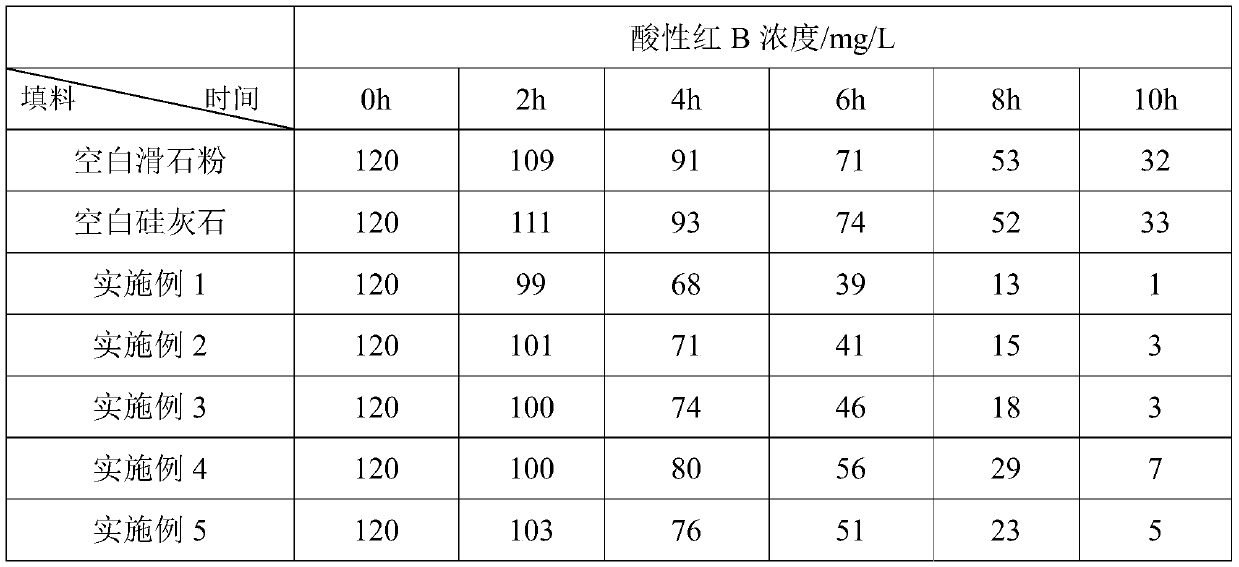

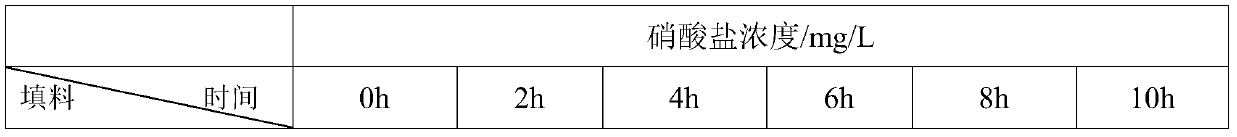

Examples

Embodiment 1

[0037]Stir 100 parts of methanol, 12 parts of 3-mercaptopropyltrimethoxysilane and 1 part of dilute hydrochloric acid with a mass concentration of 0.1 wt% at room temperature for 0.5 hours, add them to 50 parts of 5 μm talcum powder, raise the temperature to 50 ° C, and react 2 hours, cooling down, filtering, filtering out solids, washing with absolute ethanol three times, and drying to obtain mercaptopropyl modified talc powder 1.

[0038] Add 100 parts of mercaptopropyl modified talc powder 1, 10 parts of 1-allyloxy-4-hydroxyanthraquinone-9,10-dione, 300 parts of tetrahydrofuran and 3 parts of benzoin ethyl ether into the container, and stir at room temperature Irradiate for 5 minutes under ultraviolet light with a dominant wavelength of 365 nm and a light intensity of 100 W / cm, filter, wash the filtered solid with absolute ethanol three times, and dry to obtain talc powder 1 grafted with a redox mediator.

[0039] FT-IR analysis, the product is at 1669cm -1 A strong and sh...

Embodiment 2

[0041] Stir 100 parts of methanol, 20 parts of 3-mercaptopropyltrimethoxysilane and 1 part of dilute hydrochloric acid with a mass concentration of 0.1 wt% at room temperature for 0.5 hours, add them to 50 parts of 20 μm talcum powder, heat up to 50 ° C, and react 2 hours, cooling down, filtering, filtering out solids, washing with absolute ethanol 3 times, and drying to obtain mercaptopropyl modified talc powder 2.

[0042] Add 100 parts of mercaptopropyl-modified talc powder 2, 20 parts of 1-allyloxy-4-hydroxyanthraquinone-9,10-dione, 500 parts of tetrahydrofuran and 4 parts of benzoin dimethyl ether into the container at room temperature Under stirring, irradiate for 25 minutes under ultraviolet light with a dominant wavelength of 365 nm and a light intensity of 20 W / cm, filter, and wash the filtered solid three times with absolute ethanol, and dry to obtain talc powder 2 grafted with a redox mediator.

[0043] The S element content of talc powder before and after grafting ...

Embodiment 3

[0045] Stir 100 parts of absolute ethanol, 25 parts of 3-mercaptopropyltriethoxysilane and 1 part of dilute hydrochloric acid with a mass concentration of 0.1 wt% at room temperature for 1 hour, add them to 100 parts of 100 μm tourmaline, and heat up to 70 °C , reacted for 3 hours, lowered the temperature, filtered, the filtered solid was washed 3 times with absolute ethanol, and dried to obtain mercaptopropyl-modified wollastonite 1.

[0046] Add 100 parts of mercaptopropyl modified wollastonite 1, 30 parts of 1-allyloxy-4-hydroxyanthraquinone-9,10-dione, 800 parts of toluene and 6 parts of benzoin dimethyl ether into the container, Under stirring at room temperature, irradiate for 5 minutes under ultraviolet light with a dominant wavelength of 365 nm and a light intensity of 150 W / cm, filter, and wash the filtered solid with absolute ethanol three times, and dry to obtain wollastonite 1 grafted with a redox mediator.

[0047] The S element content of wollastonite before and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com