Zero-discharge combination process for livestock and poultry breeding sewage

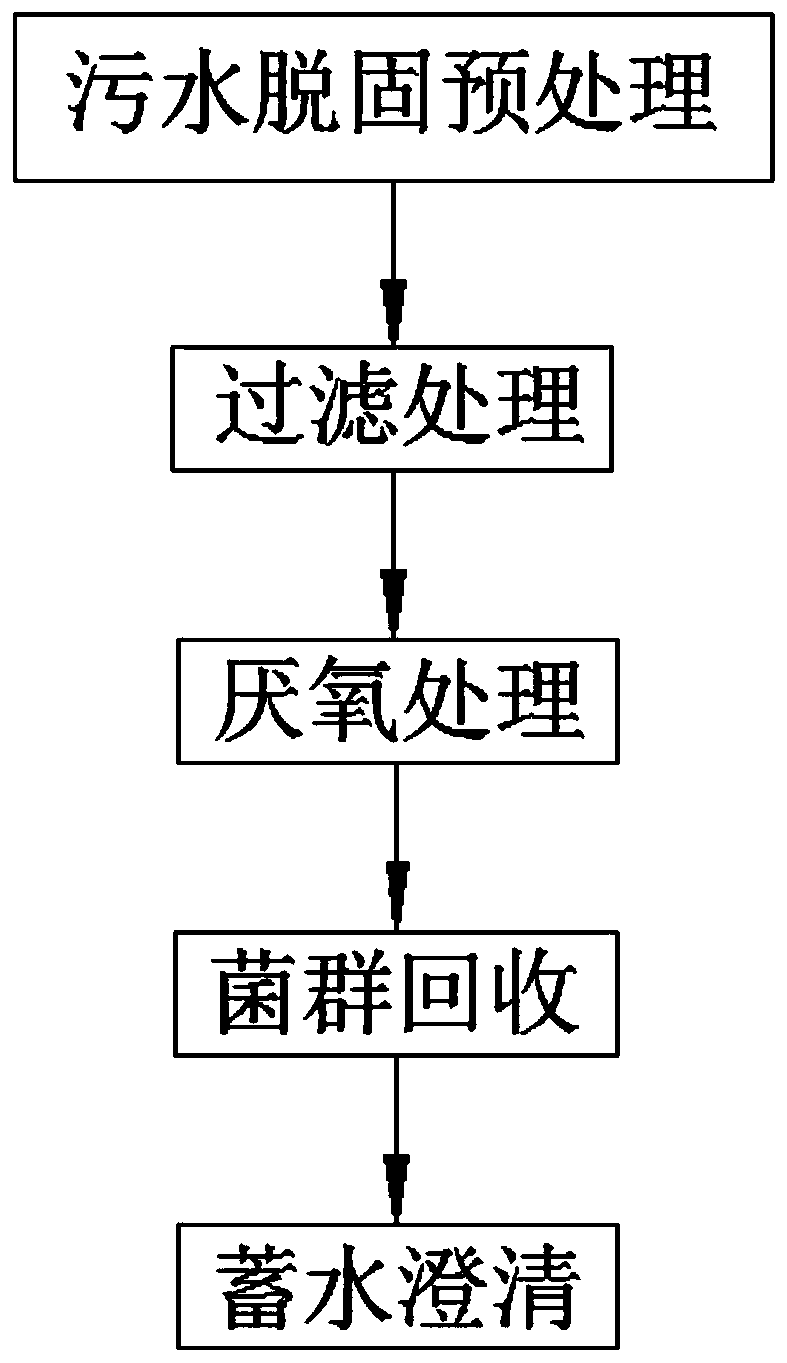

A combined process, livestock and poultry breeding technology, applied in the field of livestock and poultry breeding sewage treatment, can solve the problems of overwhelmed breeding enterprises or individuals, lack of environmental protection technology and technology, investment waste, etc., to achieve targeted selection and improve biodegradation. Speed, the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of livestock and poultry breeding sewage zero-discharge combined process proposed by the present invention is applied to slaughterhouse wastewater treatment, the experimental process is as follows:

[0030] Type of wastewater: slaughter wastewater;

[0031] Location: a slaughterhouse

[0032] Device processing capacity: 60L / h

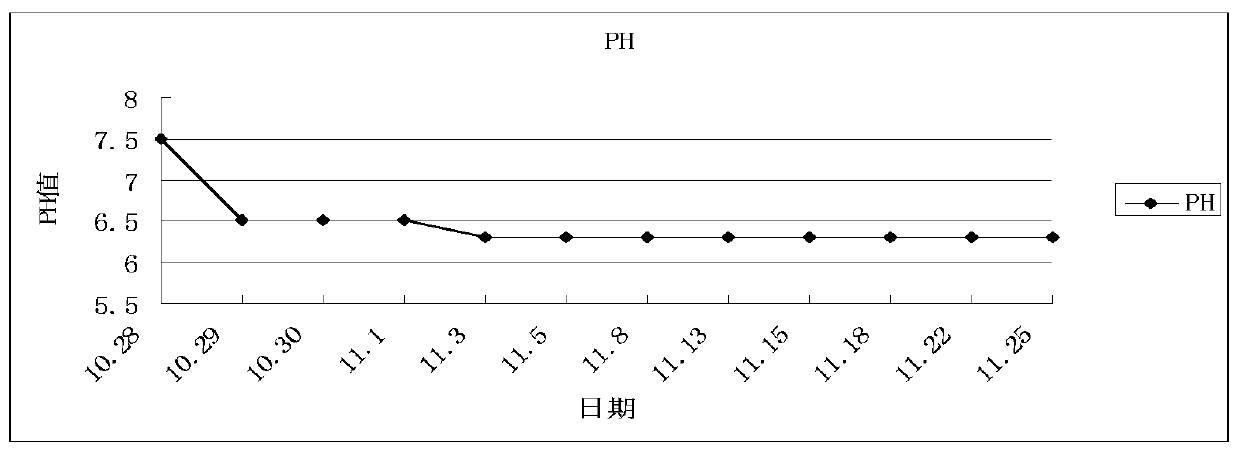

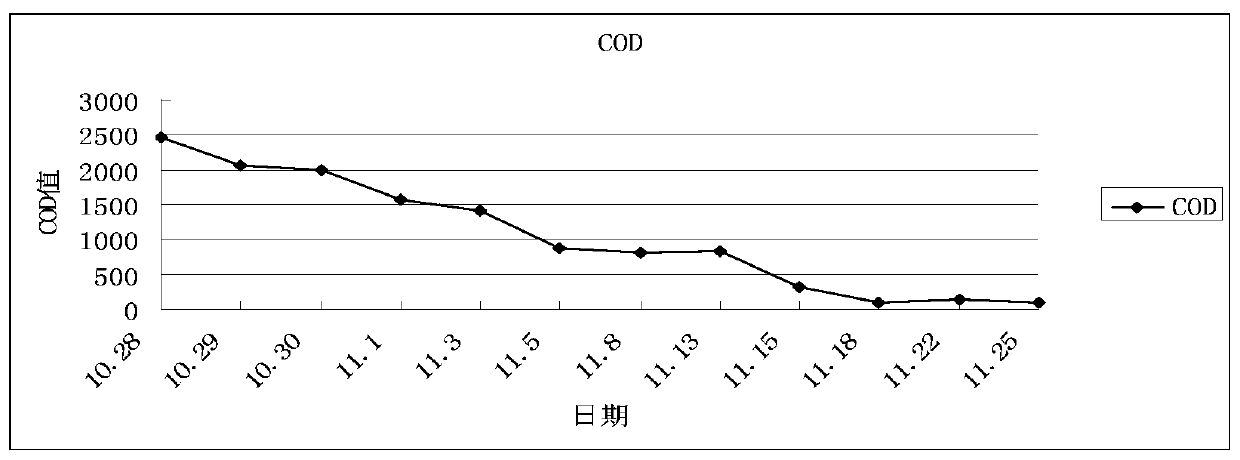

[0033] In addition to pig feces, there are pig viscera in the slaughter wastewater, resulting in a higher COD concentration than conventional slaughter wastewater. Pretreatment of slaughter wastewater is the first key treatment link. Pretreatment includes filter tank filtration + flocculation sedimentation, after filtering in the filter tank , there is no visible suspended matter in the wastewater, the water color is light yellow, and the pH value is 7.5. The flocculant is FeO2.

[0034] Obligate bacteria inoculation operation

[0035] A. Addition amount of inoculum After activation, the obligate bacteria liquid and nutrie...

Embodiment 2

[0051] Embodiment 2, a kind of livestock and poultry breeding sewage zero-discharge combined process proposed by the present invention is applied to pig farm wastewater treatment, the experimental process is as follows:

[0052] Wastewater type: Pig flushing waste water;

[0053] Location: a pig farm

[0054] Device processing capacity: 10m 3 / d (belongs to dry manure)

[0055] Pig farms use dry and clean manure to wash pens, and the waste water is rich in pig excrement. The data are as follows:

[0056]

[0057]

[0058]On the 13th day after 12 days of operation, the water intake starts, and the amount of water intake is as follows:

[0059]

[0060] The dosing position of the microbial strains in the table: the seeding period (first day) is added to the water inlet of the biological aerated filter, and the maintenance period (after the third day) is also added to the water inlet of the biological filter; Agent activation method: Dissolve the product at a rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com