Preparation method and application of plastic with anthraquinone compound-grafted surface

A technology of surface grafting and compounding, which is applied in the field of preparation of anthraquinone compound grafting on the surface of plastics, can solve the problems of poor versatility and high price of macroporous foam, and achieve the effects of low cost, accelerated biodegradation rate, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

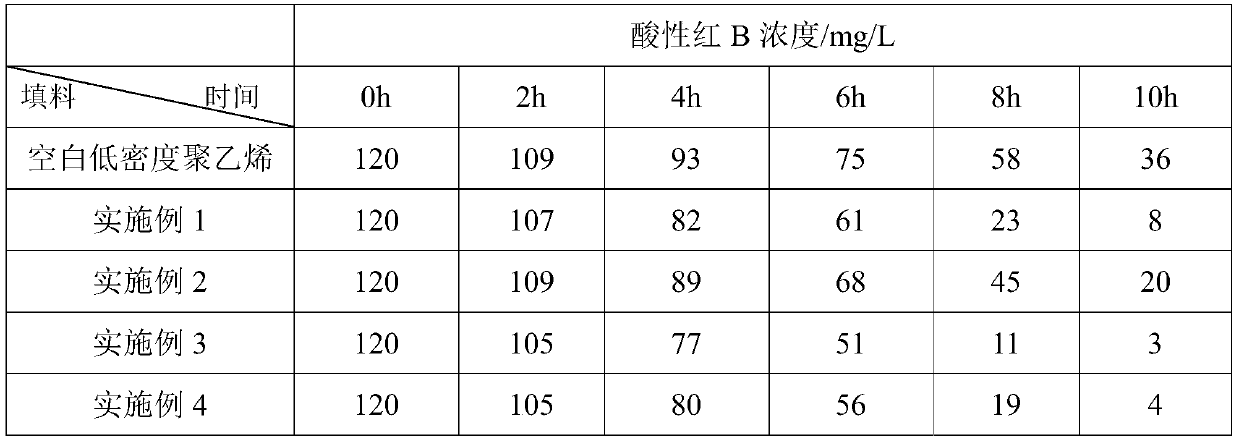

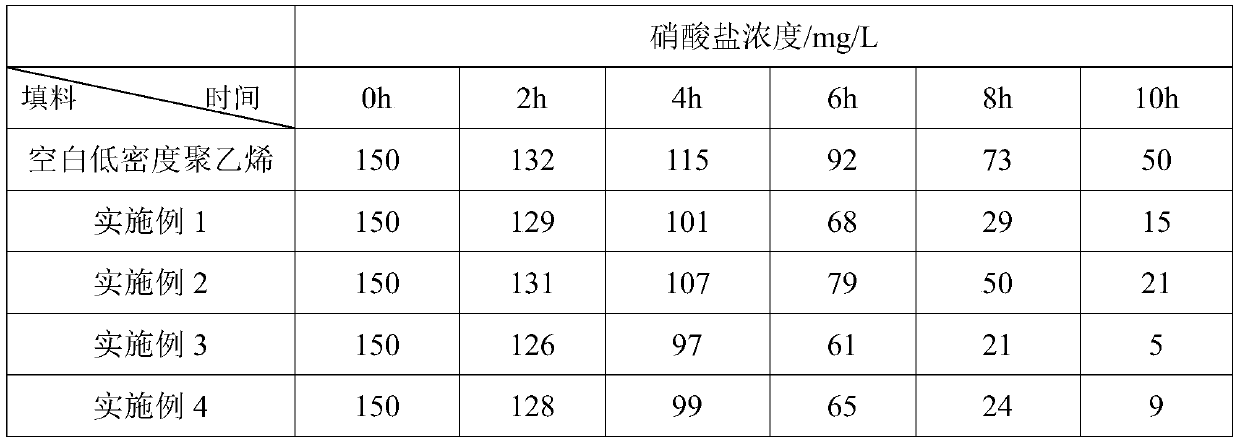

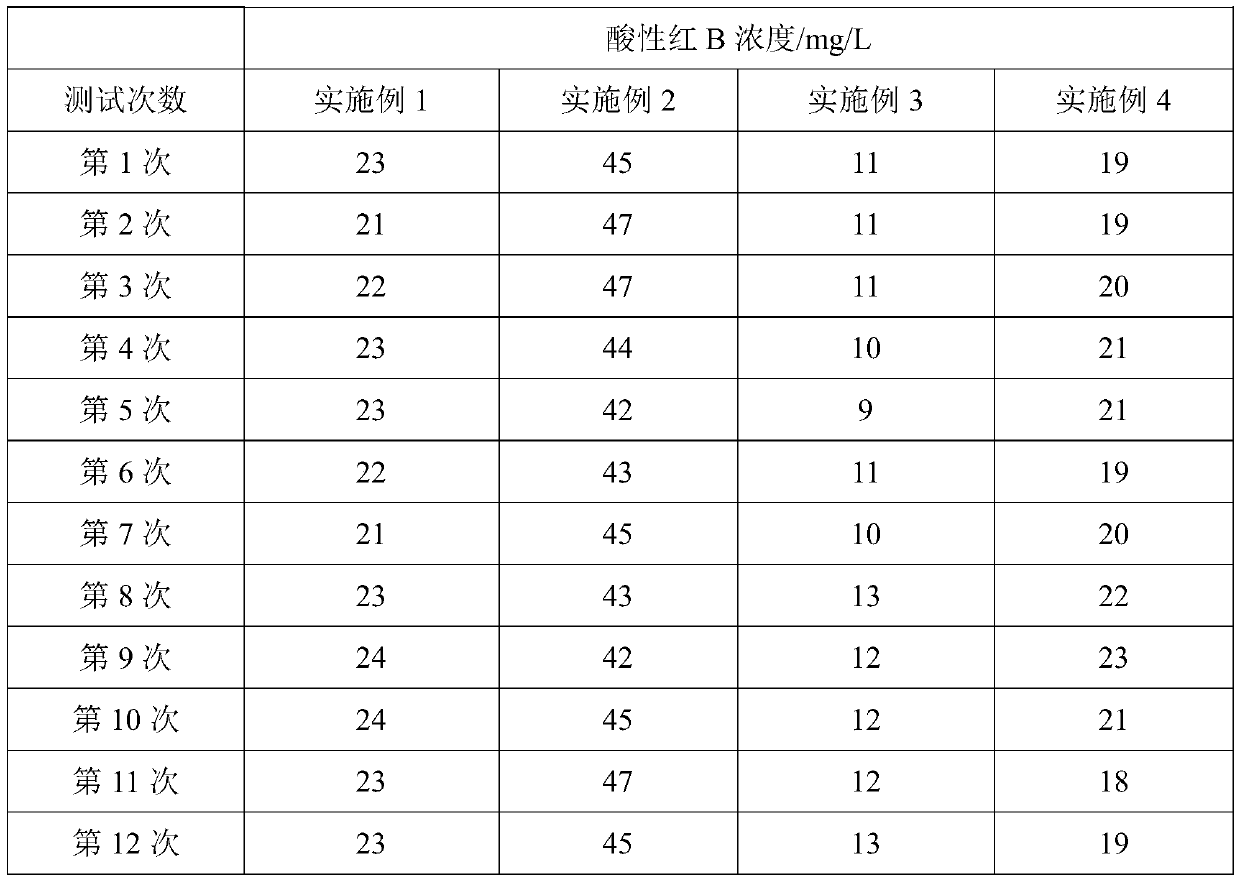

Examples

Embodiment 1

[0037] The surface of low-density PE plastic with an average particle size of 0.2 mm is hydrophilically modified by ozone.

[0038] Add 7 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, and add 30 parts of the above-mentioned surface hydrophilic low-density PE For plastics, heat up to 60°C, react for 2 hours, filter, filter out solids, wash with absolute ethanol three times, and dry to obtain epoxy-modified low-density PE plastics.

[0039] Add 100 parts of 2-aminoanthraquinone and 2 parts of triethylamine into 400 parts of tetrahydrofuran, stir evenly, add 100 parts of the above-mentioned epoxy-modified low-density PE plastic, stir at room temperature for 1 hour, filter, and filter out the solid with free Washing with water and ethanol for three times and drying to obtain low-density PE plastics grafted with anthraquinone compound on the surface. FT-IR analysis, the product is at 15...

Embodiment 2

[0042] Hydrophilic modification of the surface of semi-soft packing used in sewage treatment was carried out by using ozone.

[0043] Add 5 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, and add 30 parts of the above-mentioned semi-soft surface hydrophilic The filler was heated to 60°C, reacted for 2 hours, filtered, and the filtered solid was washed three times with absolute ethanol and dried to obtain an epoxy-modified semi-soft filler.

[0044] Add 100 parts of 2-aminoanthraquinone and 3 parts of triethylamine into 500 parts of tetrahydrofuran, stir evenly, add 150 parts of the above-mentioned epoxy-modified semi-soft filler, stir at room temperature for 5 hours, filter, and filter out the solid with free Washing with water and ethanol for three times and drying to obtain a semi-soft filler grafted with anthraquinone compound on the surface.

[0045] The elemental analysis method...

Embodiment 3

[0047] The surface of PP plastic with an average particle size of 0.05 mm is hydrophilically modified by plasma.

[0048] Add 8 parts of 3-(2,3-glycidoxy)propyltriethoxysilane to 100 parts of alcohol aqueous solution with a volume ratio of 95:5, stir for half an hour, and add 30 parts of the above-mentioned surface-hydrophilic PP plastic , heated up to 65°C, reacted for 2 hours, filtered, and the filtered solid was washed three times with absolute ethanol and dried to obtain epoxy-modified PP plastic.

[0049] Add 100 parts of 1-amino-2-bromo-4-hydroxyanthraquinone and 2 parts of triethylamine into 500 parts of tetrahydrofuran, stir evenly, add 100 parts of the above-mentioned epoxy-modified PP plastic, stir at room temperature for 2 hours, filter , filtered out the solid, washed three times with absolute ethanol, and dried to obtain a PP plastic grafted with anthraquinone compound on the surface. FT-IR analysis, product at 1589cm -1 The sharp absorption peak at 1635cm is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com