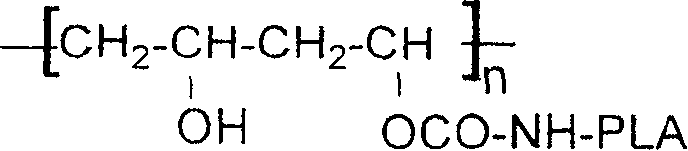

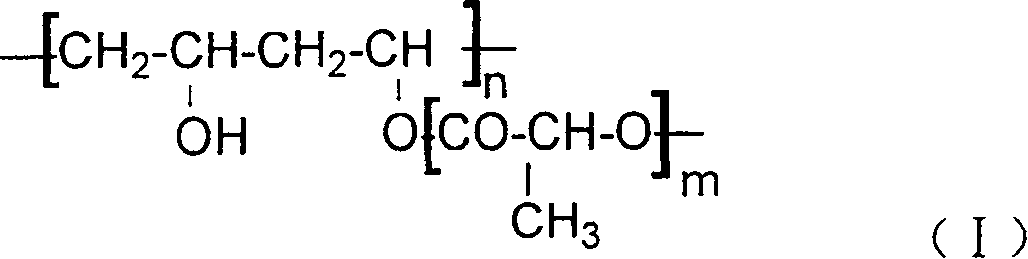

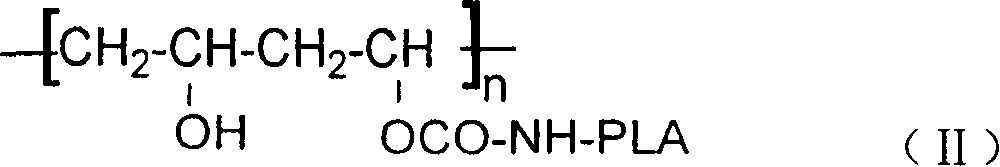

Blend material of vinol/polylactic acid graft copolymer and starch, their preparing method and application

A technology of graft copolymer and polyvinyl alcohol, which is applied in the field of blended materials and their preparation, can solve the problems of decreased yield and increased production cost, and achieve the effects of easy control, improved toughness and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Put 90 parts of polyvinyl alcohol (1799) and 10 parts of lactic acid into the reactor, swell at 70°C for 1.5 hours, add 0.5 parts of stannous chloride catalyst, and then dehydrate and copolymerize at 120°C for 3 hours to obtain polyethylene Alcohol / polylactic acid graft copolymer. The unreacted lactic acid monomer and polylactic acid homopolymer in the copolymer were extracted with toluene, dried in vacuum at 80°C for 48 hours, and the purified product was analyzed by NMR and differential scanning calorimetry. The results showed that the graft chain The degree of graft polymerization is 8, and the grafting rate is 31%. The glass transition temperature of the graft was 52°C and the melting point was 139°C.

Embodiment 2

[0036] Put 80 parts of polyvinyl alcohol (1788) and 20 parts of lactic acid into the reactor, after swelling at 85°C for 2 hours, add 4 parts of stannous octoate catalyst, and then dehydrate and copolymerize at 100°C for 5 hours to obtain polyvinyl alcohol / Polylactic acid graft copolymer. The unreacted lactic acid monomer and polylactic acid homopolymer in the copolymer were extracted with toluene, dried in vacuum at 80°C for 48 hours, and the purified product was analyzed by NMR and differential scanning calorimetry. The results showed that the graft chain The degree of graft polymerization is 5, and the grafting rate is 39%. The glass transition temperature of the graft was 53°C and the melting point was 138°C.

Embodiment 3

[0038] Put 30 parts of polyvinyl alcohol (0599) and 70 parts of lactic acid into the reactor, after swelling at 90°C for 2.5 hours, add 2.5 parts of zinc chloride catalyst, and then dehydrate and copolymerize at 125°C for 3.5 hours to obtain polyvinyl alcohol / Polylactic acid graft copolymer. The unreacted lactic acid monomer and polylactic acid homopolymer in the copolymer were extracted with toluene, dried in vacuum at 80°C for 48 hours, and the purified product was analyzed by NMR and differential scanning calorimetry. The results showed that the graft chain The degree of graft polymerization is 12, and the grafting rate is 43%. The glass transition temperature of the graft was 58°C and the melting point was 104°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com