Degradable cotton swab and preparation method thereof

A cotton swab and accelerator technology, applied in the field of medical supplies, can solve the problems of non-degradable polypropylene and environmental pollution, and achieve the effects of good antibacterial effect, reducing pollution and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

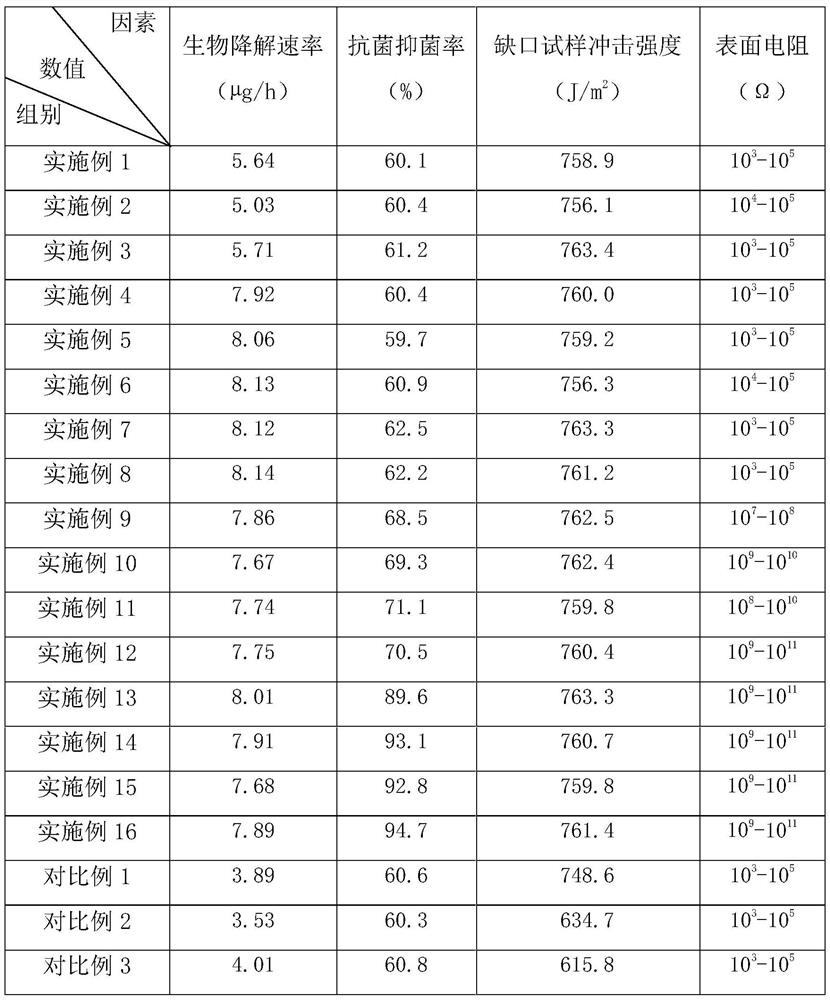

Examples

Embodiment 1

[0035] This embodiment discloses a degradable cotton swab stick;

[0036] Wherein the production of the degradable cotton swab stick is as follows:

[0037] S1, 130g polybutylene succinate, 85g polylactic acid, 15g kaolin (filler), 10g polypropylene carbonate (toughener), 4g aluminate coupling agent (compatibilizer) and 2g Adipic acid (degradation accelerator) was heated to 120°C and stirred for 25 minutes to obtain a blend;

[0038] S2, extruding and cooling the blended material to obtain a raw material rod;

[0039] S3, cutting the raw material stick to obtain a shaped cotton swab stick.

Embodiment 2

[0041] This embodiment discloses a degradable cotton swab stick;

[0042] Wherein the production of the degradable cotton swab stick is as follows:

[0043] S1, 126g polybutylene succinate, 90g polylactic acid, 25g kaolin (filler), 5g polypropylene carbonate (toughening agent), 5g aluminate coupling agent (compatibilizer) and 1g Adipic acid (degradation accelerator) was heated to 150°C and stirred for 20 minutes to obtain a blend;

[0044] S2, extruding and cooling the blended material to obtain a raw material rod;

[0045] S3, cutting the raw material stick to obtain a shaped cotton swab stick.

Embodiment 3

[0047] This embodiment discloses a degradable cotton swab stick;

[0048] Wherein the production of the degradable cotton swab stick is as follows:

[0049] S1, 110g polybutylene succinate, 70g polylactic acid, 18g kaolin (filler), 6g polypropylene carbonate (toughener), 3g aluminate coupling agent (compatibilizer) and 1.5 g adipic acid (degradation accelerator) was heated to 130°C and stirred for 23min to obtain a blend;

[0050] S2, extruding and cooling the blended material to obtain a raw material rod;

[0051] S3, cutting the raw material stick to obtain a shaped cotton swab stick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com